66832-UIM-D-1205

2

Unitary Products Group

SPECIFIC SAFETY RULES AND PRECAUTIONS

1.

Only Natural gas or Propane (LP) gas are approved for use with

this furnace. Refer to the furnace rating plate or Section IV of

these instructions.

2.

Install this furnace only in a location and position as specified in

SECTION I of these instructions.

3.

A gas-fired furnace for installation in a residential garage must be

installed as specified in SECTION I of these instructions.

4.

Provide adequate combustion and ventilation air to the furnace

space as specified in SECTION VII of these instructions.

5.

Combustion products must be discharged outdoors. Connect this

furnace to an approved vent system only, as specified in SEC-

TION VII of these instructions.

6.

Test for gas leaks as specified in SECTION XI of these instruc-

tions.

7.

Always install the furnace to operate within the furnace’s intended

temperature rise range. Only connect the furnace to a duct system

which has an external static pressure within the allowable range,

as specified on the furnace rating plate.

8.

When a furnace is installed so that supply ducts carry air circulated

by the furnace to areas outside the space containing the furnace,

the return air shall also be handled by duct(s) sealed to the fur-

nace casing and terminating outside the space containing the fur-

nace.

9.

It is permitted to be use the furnace for heating of buildings or

structures under construction. Installation must comply with all

manufacturer’s installation instructions including:

•

Proper vent installation;

•

Furnace operating under thermostatic control;

•

Return air duct sealed to the furnace;

•

Air filters in place;

•

Set furnace input rate and temperature rise per rating plate

marking;

•

Means for providing outdoor air required for combustion;

•

Return air temperature maintained between 55ºF (13ºC) and

80ºF (27ºC);

•

The air filter must be replaced upon substantial completion of

the construction process;

•

Clean furnace, duct work and components upon substantial

completion of the construction process, and verify furnace-

operating conditions including ignition, input rate, temperature

rise and venting, according to the manufacturer’s instructions.

The following requirements to be met:

a.

Clean, outside combustion air is provided to the furnace to

minimize the impact of corrosive adhesives, sealants, and

other construction materials. Drywall dust is a major concern

during construction, which can be pulled into the combustion

air path, leading to plugged gas valves, burners, and inducer

assemblies.

b.

Filter must be installed in the furnace as specified in the

installation instructions, and must be replaced or thoroughly

cleaned prior to occupancy of the home. Again, drywall dust

is the key issue, as that dust can be pulled into the circulating

blower motor, plugging the motor vents, coating the rotors

and stators, etc. which can lead to a potential fire hazard.

c.

The temperature of the return air to the furnace must not be

less than 55 degrees F (13 deg C), with no evening setback

or furnace shutdown, to prevent condensation in the primary

heat exchangers.

d.

The air temperature rise must be within the stated rise range

as indicated on the furnace rating plate, and the firing input

rate must be set to the unit nameplate value.

e.

The external static pressure of the air distribution system

ductwork must at set for heating operation to be at least 0.10

to 0.20 inches water column, based on the input rate of the

furnace, with the lower value for input rates less than 55,000

btu/hr and the upper value for units with input rates above

100,000 btu/hr.

f.

A return air duct must be used, sealed to the furnace cabinet,

and terminated outside the space where the furnace is

installed. This prevents any recirculation of supply air, which

can generate a negative pressure condition at the furnace for

non-direct vent furnaces, leading to possible flame rollout or

combustion problems.

g.

The furnace and ductwork should be thoroughly and com-

pletely cleaned prior to occupancy of the dwelling to insure

the proper operation of the furnace and to avoid potential

health concerns.

10. When installed in a Non-HUD-Approved Modular Home or building

constructed on-site, combustion air shall not be supplied from

occupied spaces.

11.

The size of the unit should be based on an acceptable heat loss

calculation for the structure. ACCA, Manual J or other approved

methods may be used.

SAFETY REQUIREMENTS

•

This furnace should be installed in accordance with all national

and local building/safety codes and requirements, local plumbing

or wastewater codes, and other applicable codes. In the absence

of local codes, install in accordance with the National Fuel Gas

Code ANSI Z223.1/NFPA 54, National Fuel Gas Code, and/or

CAN/CGA B149.1 Natural Gas and Propane Installation Code

(latest editions). Furnaces have been certified to the latest edition

of standard ANSI Z21-47 • CSA 2.3.

•

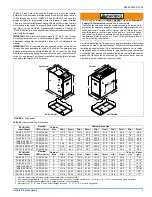

Refer to the unit rating plate for the furnace model number, and

then see the dimensions page of this instruction for return air ple-

num dimensions in Figure 5. The plenum must be installed

according to the instructions.

•

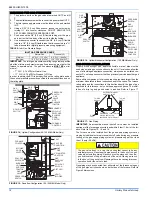

Provide clearances from combustible materials as listed under

Clearances to Combustibles.

•

Provide clearances for servicing ensuring that service access is

allowed for both the burners and blower.

•

These models ARE NOT CSA listed or approved for installation

into a HUD Approved Modular Home or a Manufactured

(Mobile) Home.

•

This furnace is not approved for installation in trailers or recre-

ational vehicles.

•

Failure to carefully read and follow all instructions in this

manual can result in furnace malfunction, death, personal

injury and/or property damage.

•

Furnaces for installation on combustible flooring shall not be

installed directly on carpeting, tile or other combustible material

other than wood flooring.

•

Check the rating plate and power supply to be sure that the elec-

trical characteristics match. All models use nominal 115 VAC, 1

Phase, 60-Hertz power supply. DO NOT CONNECT THIS APPLI-

ANCE TO A 50 HZ POWER SUPPLY OR A VOLTAGE ABOVE

130 VOLTS.

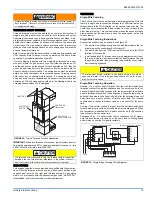

FIRE OR EXPLOSION HAZARD

Failure to follow the safety warnings exactly could result in serious

injury, death or property damage.

Never test for gas leaks with an open flame. Use a commercially

available soap solution made specifically for detection of leaks to

check all connections. A fire or explosion may result causing prop-

erty damage, personal injury or loss of life.