66832-UIM-D-1205

Unitary Products Group

3

•

Furnace shall be installed so the electrical components are pro-

tected from water.

•

Installing and servicing heating equipment can be hazardous due

to the electrical components and the gas fired components. Only

trained and qualified personnel should install, repair, or service

gas heating equipment. Untrained service personnel can perform

basic maintenance functions such as cleaning and replacing the

air filters. When working on heating equipment, observe precau-

tions in the manuals and on the labels attached to the unit and

other safety precautions that may apply.

•

These instructions cover minimum requirements and conform to

existing national standards and safety codes. In some instances

these instructions exceed certain local codes and ordinances,

especially those who have not kept up with changing residential

and non-HUD modular home construction practices. These

instructions are required as a minimum for a safe installation.

COMBUSTION AIR QUALITY

(LIST OF CONTAMINANTS)

The furnace will require OUTDOOR AIR for combustion when the fur-

nace is located in any of the following environments.

•

Restricted Environments

•

Commercial buildings

•

Buildings with indoor pools

•

Furnaces installed in laundry rooms

•

Furnaces installed in hobby or craft rooms

•

Furnaces installed near chemical storage areas

•

Chemical Exposure

The furnace will require OUTDOOR AIR for combustion when the fur-

nace is located in an area where the furnace is being exposed to the fol-

lowing substances and / or chemicals.

•

Permanent wave solutions

•

Chlorinated waxes and cleaners

•

Chlorine based swimming pool chemicals

•

Water softening chemicals

•

De-icing salts or chemicals

•

Carbon tetrachloride

•

Halogen type refrigerants

•

Cleaning solvents (such as perchloroethylene)

•

Printing inks, paint removers, varnishes, etc.

•

Hydrochloric acid

•

Cements and glues

•

Antistatic fabric softeners for clothes dryers

•

Masonry acid washing materials

If outdoor air is used for combustion, the combustion air intake duct sys-

tem termination must be located external to the building and in an area

where there will be no exposure to the substances listed above.

INSPECTION

As soon as a unit is received, it should be inspected for possible dam-

age during transit. If damage is evident, the extent of the damage

should be noted on the carrier’s freight bill. A separate request for

inspection by the carrier’s agent should be made in writing. Also, before

installation the unit should be checked for screws or bolts, which may

have loosened in transit, and any shipping or spacer brackets which

need to be removed.

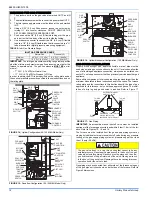

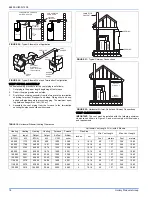

FURNACE LOCATION AND CLEARANCES

The furnace shall be located using the following guidelines:

1.

Where a minimum amount of air intake/vent piping and elbows will

be required.

2.

As centralized with the air distribution as possible.

3.

Where adequate combustion air will be available (particularly

when the appliance is not using outdoor combustion air).

4.

Where it will not interfere with proper air circulation in the confined

space.

5.

Where the outdoor vent terminal will not be blocked or restricted.

Refer to “VENT CLEARANCES” located in SECTION VII of these

instructions. These minimum clearances must be maintained in

the installation.

6.

Where the unit will be installed in a level position with no more

than 1/4” (0.64 cm) slope side-to-side and front-to-back to provide

proper condensate drainage.

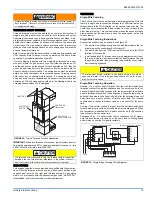

Installation in freezing temperatures:

1.

Furnace shall be installed in an area where ventilation facilities

provide for safe limits of ambient temperature under normal oper-

ating conditions. Ambient temperatures falling below 32° F (0° C)

may result in the flue temperature falling below 260° F (127° C) at

any point in the flue pipe between the furnace and the chimney or

a B-Vent. The flue products will condense in the vent pipe if the

flue temperature falls below 260° F (127° C) causing the vent pipe

to deteriorate rapidly.

2.

Do not allow return air temperature to be below 55º F (13° C) for

extended periods. To do so may cause condensation to occur in

the main heat exchanger, leading to premature heat exchanger

failure.

3.

If this furnace is installed in an unconditioned space and an

extended power failure occurs, there will be potential damage to

the internal components. Following a power failure situation, do

not operate the unit until inspection and repairs are performed.

Clearances for access:

Ample clearances should be provided to permit easy access to the unit.

The following minimum clearances are recommended:

1.

Twenty-four (24) inches (61 cm) between the front of the furnace

and an adjacent wall or another appliance, when access is

required for servicing and cleaning.

2.

Eighteen (18) inches (46 cm) at the side where access is required

for passage to the front when servicing or for inspection or

replacement of flue/vent connections.

In all cases, accessibility clearances shall take precedence over clear-

ances for combustible materials where accessibility clearances are

greater.

The furnace area must not be used as a broom closet or for any

other storage purposes, as a fire hazard may be created. Never

store items such as the following on, near or in contact with the fur-

nace.

1. Spray or aerosol cans, rags, brooms, dust mops, vacuum

cleaners or other cleaning tools.

2. Soap powders, bleaches, waxes or other cleaning com-

pounds; plastic items or containers; gasoline, kerosene, ciga-

rette lighter fluid, dry cleaning fluids or other volatile fluid.

3. Paint thinners and other painting compounds.

4. Paper bags, boxes or other paper products

Never operate the furnace with the blower door removed. To

do so could result in serious personal injury and/or equipment

damage.

Improper installation in an ambient below 32ºF (0.0° C) could create

a hazard, resulting in damage, injury or death.