66832-UIM-D-1205

4

Unitary Products Group

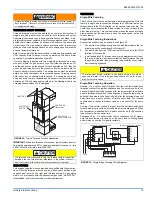

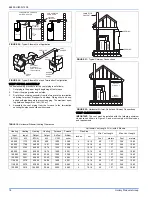

Installation in a residential garage:

A gas-fired furnace for installation in a residential garage must be

installed so the burner(s) and the ignition source are located not less

than (18) inches (46 cm) above the floor, and the furnace must be

located or protected to avoid physical damage by vehicles.

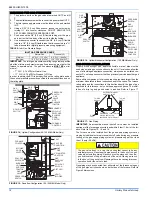

SECTION II: DUCTWORK

DUCTWORK GENERAL INFORMATION

The duct system’s design and installation must:

1.

Handle an air volume appropriate for the served space and within

the operating parameters of the furnace specifications.

2.

Be installed in accordance with standards of NFPA (National Fire

Protection Association) as outlined in NFPA pamphlets 90A and

90B (latest editions) or applicable national, provincial, or state, and

local fire and safety codes or in Canada, refer to the Natural Gas

and Propane Installation Code B149.1-00.

3.

Create a closed duct system. For residential and Non-HUD Modu-

lar Home installations, when a furnace is installed so that the sup-

ply ducts carry air circulated by the furnace to areas outside the

space containing the furnace, the return air shall also be handled

by a duct(s) sealed to the furnace casing and terminating outside

the space containing the furnace.

4.

Complete a path for heated or cooled air to circulate through the

air conditioning and heating equipment and to and from the condi-

tioned space.

When the furnace is used in conjunction with a cooling coil, the coil

must be installed parallel with, or in the supply air side of the furnace to

avoid condensation in the primary heat exchanger. When a parallel flow

arrangement is used, dampers or other means used to control airflow

must be adequate to prevent chilled air from entering the furnace. If

manually operated, the damper must be equipped with means to pre-

vent the furnace or the air conditioner from operating unless the damper

is in full heat or cool position.

INSTALLATION POSITION (50-125 MBH Models)

This furnace may be installed in an upflow, downflow or horizontal posi-

tion. Depending on the configuration shipped from the factory, it may be

necessary to convert the furnace from downflow to upflow or from

upflow to downflow configuration. Use conversion instructions in this

document.

INSTALLATION POSITION (150 MBH Models)

This furnace may be installed in an upflow or horizontal position. No

conversion is necessary. This furnace is not approved for downflow

application.

CONVERSION INFORMATION (50-125 MBH Models)

This furnace may be shipped in either the upflow or the downflow con-

figuration. To convert from upflow to downflow or vice-versa it is neces-

sary only to exchange the top and bottom casing caps and to rotate the

vent blower 180 degrees. Use the step by step instructions to perform

the conversion.

Downflow furnaces for installation on combustible flooring only

when installed on the accessory combustible floor base on wood

flooring only and shall not be installed directly on carpeting, tile or

other combustible material.

Check the rating plate and power supply to be sure that the electri-

cal characteristics match. All models use nominal 115 VAC, 1

Phase 60Hz power supply.

Furnace shall be installed so the electrical components are pro-

tected from water.

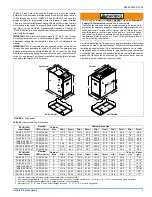

TABLE 1: Unit Clearances to Combustibles

APPLICATION

TOP

FRONT

REAR

SIDES SINGLE WALL VENT

FLOOR/

BOTTOM

CLOSET ALCOVE ATTIC

LINE

CONTACT

In. (cm) In. (cm) In. (cm) In. (cm)

In. (cm)

UPFLOW

1 (25.4)

2 (5.08)

0 (0.0)

0 (0.0)

6 (15.24)

COMBUSTIBLE

YES

YES

YES

NO

UPFLOW B-VENT

1 (25.4)

3 (7.62)

0 (0.0)

0 (0.0)

6 (15.24)

COMBUSTIBLE

YES

YES

YES

NO

HORIZONTAL

1 (25.4)

2 (5.08)

0 (0.0)

1 (5.08)

6 (15.24)

COMBUSTIBLE

NO

YES

YES

YES

1

1. Line contact only permitted between lines formed by the intersection of the rear panel and side panel (top in horizontal position) of the furnace jacket and building

joists, studs or framing.

HORIZONTAL B-VENT

1 (25.4)

3 (7.62)

0 (0.0)

0 (0.0)

6 (15.24)

COMBUSTIBLE

NO

YES

YES

YES

1

DOWNFLOW

1 (25.4)

2 (5.08)

0 (0.0)

0 (0.0)

6 (15.24)

NON-COMBUSTIBLE

YES

YES

YES

NO

DOWNFLOW B-VENT

1 (25.4)

3 (7.62)

0 (0.0)

0 (0.0)

6 (15.24)

NON-COMBUSTIBLE

YES

YES

YES

NO

The cooling coil must be installed in the supply air duct, down-

stream of the furnace. Cooled air may not be passed over the heat

exchanger.

The duct system must be properly sized to obtain the correct airflow

for the furnace size that is being installed.

Refer to Table 8 and the furnace rating plate for the correct rise

range and static pressures

If the ducts are undersized, the result will be high duct static pres-

sures and/or high temperature rises which can result in a heat

exchanger OVERHEATING CONDITION. This condition can result

in premature heat exchanger failure, which can result in personal

injury, property damage, or death.