66832-UIM-D-1205

6

Unitary Products Group

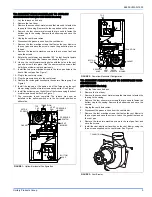

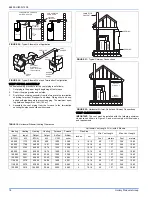

10. Rotate the vent blower 180º so that its outlet points toward the inlet

air end of the furnace. See Figure 2.

11.

Line up the vent blower mounting holes with the holes in the vent

pan and screw it into place. Use the same machine screws that

held the vent blower in place previously.

12. Install the two extra machine screws in the two open holes in the

front of the vent pan. See Figure 2.

13. Plug in the vent motor wires.

14. Plug the pressure hose into the vent blower.

15. Remove the round knockout at the right side of the top cap. See

Figure 4.

16. Install the top cap at the opposite end of furnace from the vent

blower, using the seven sheet metal screws saved earlier. See

Figure

2.

17. Install the bottom cap on the bottom of the furnace using the sheet

metal screws saved earlier. See Figure 2.

18. The conversion is now complete. The furnace may now be

installed in the downflow position or in the horizontal position on

either side.

INSTALLATION POSITION (150 MBH Models)

This furnace may be installed in an upflow or horizontal position. No

conversion is necessary. This furnace is not approved for downflow

application.

FLOOR BASE AND DUCTWORK INSTALLATION

Upflow Instructions

Attach the supply plenum to the furnace outlet duct

connection flanges. This is typically through the use of

S cleat material when a metal plenum is used. The use

of an approved flexible duct connector is recom-

mended on all installations. This connection should be

sealed to prevent air leakage. The sheet metal should

be cross-hatched to eliminate any popping of the

sheet metal when the indoor fan is energized.

When replacing an existing furnace, if the existing plenum is not the

same size as the new furnace then the existing plenum must be

removed and a new plenum installed that is the proper size for the new

furnace. If the plenum is shorter than 12” (30.5 cm) the turbulent air flow

may cause the limit controls not to operate as designed, or the limit con-

trols may not operate at all.

The duct system is a very important part of the installation. If the duct

system is improperly sized the furnace will not operate properly.

The ducts attached to the furnace plenum, should be of sufficient size

so that the furnace operates at the specified external static pressure

and within the air temperature rise specified on the nameplate.

Table 2 is a guide for determining whether the rectangular duct system

that the furnace is being connected to be of sufficient size for proper fur-

nace operation.

Use the Example below to help you in calculating the duct area to deter-

mine whether the ducts have sufficient area so that the furnace oper-

ates at the specified external static pressure and within the air

temperature rise specified on the nameplate.

Example: The furnace input is 80,000 BTUH, 1,200 CFM. The recom-

mended duct area is 280 sq.in, there are two 8 x 14 rectangular ducts

attached to the plenum and there are two 7 inch round ducts attached to

the furnace.

1.

Take 8 x 14, which equals 112 sq.in. X 2, which equals 224 square

inch then go to round duct size located in Table 2.

2.

The square inch area for 7 inch round pipe is 38.4, multiply by 2 for

two round ducts which equals 76.8 square inch.

3.

Then take the 224 square inch from the rectangular duct and add it

to the 76.8 sq.in. of round duct. The total square inch of duct

attached to the furnace plenum is 300.8 square inch. This exceeds

the recommended 280 square inch of duct.

In this example, the duct system attached to the plenum has a sufficient

area so that the furnace operates at the specified external static pres-

sure and within the air temperature rise specified on the nameplate.

Consideration should be given to the heating capacity required and also

to the air quantity (CFM) required. These factors can be determined by

calculating the heat loss and heat gain of the home or structure. If these

calculations are not performed and the furnace is over-sized, the follow-

ing may result:

1.

Short cycling of the furnace.

2.

Wide temperature fluctuations from the thermostat setting.

3.

Reduced overall operating efficiency of the furnace.

The supply and return duct system must be of adequate size and

designed such that the furnace will operate within the designed air tem-

perature rise range and not exceed the maximum designed static pres-

sure. These values are listed Tables 2 and 3.

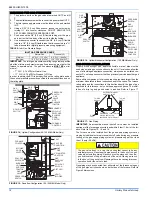

FIGURE 4: Top Cap

UPFLOW

VENT

OPENING

DOWNFLOW

VENT

OPENING

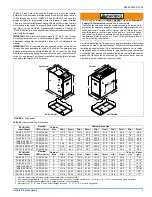

TABLE 2: Minimum Duct Sizing For Proper Airflow

Input

Airflow

Return

1

1. Maximum return air velocity in rigid duct @ 700 feet per minute (19.82 m

3

/

minute).

Rectangular

2

2. Example return main trunk duct minimum dimensions.

Round

2

Supply

3

3. Maximum supply air velocity in rigid duct @ 900 feet per minute (25.49 m

3

/

minute).

BTU/H

(kW)

CFM

(m³)

In²

(cm²)

in. x in.

(cm x cm)

in.

(cm) dia.

In²

(cm²)

50000

(14.65)

1,200

(33.98)

280

(711)

14 x 20

(35.6 x 50.8)

18

(45.7)

216

(549)

75000

(21.98)

1,200

(33.98)

280

(711)

14 x 20

(35.6 x 50.8)

18

(45.7)

216

(549)

75000

(21.98)

1,600

(45.31)

360

(914)

18 x 20

(45.7 x 50.8))

22

(55.8)

280

(711)

100000

(29.31)

1,600

(45.31)

360

(914)

18 x 20

(45.7 x 50.8)

22

(55.8)

280

(711)

100000

(29.31)

2,000

(56.63)

440

(1,118)

20 x 22

(50.8 x 55.8)

24

(60.9)

390

(991)

125000

(36.63)

2,000

(56.63)

440

(1,118)

20 x 22

(50.8 x 55.8)

24

(60.9)

390

(991)

150000

(43.96)

2,000

(56.63)

440

(1,118)

20 x 22

(50.8 x 55.8)

24

(60.9)

390

(991)

NOTE: This chart does not replace proper duct sizing calculations or take into

account static pressure drop for run length and fittings. Watch out for the temper-

ature rise and static pressures.

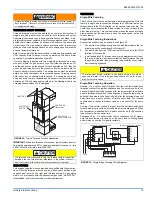

TABLE 3: External Static Pressure Range

Input

Output

Nominal

Air Flow

Ext. Static Pressure

Minimum

Maximum

MBH kW MBH kW CFM cmm In.W.C

kPa

In.W.C

kPa

50

14.7

40

11.7 1200 34.0

0.10

0.0249

0.50

0.1245

75

22.0

60

17.6 1200 34.0

0.12

0.0299

0.50

0.1245

75

22.0

60

17.6 1600 45.3

0.12

0.0299

0.50

0.1245

100

29.3

80

23.4 1600 45.3

0.15

0.0374

0.50

0.1245

100

29.3

80

23.4 2000 56.6

0.15

0.0374

0.50

0.1245

125

36.6

100 29.3 2000 56.6

0.20

0.0498

0.50

0.1245

150

44.0

120 35.2 2000 56.6

0.20

0.0498

0.50

0.1245