035-15881-402 REV. A (1199)

650.67-N2V

Unitary Products Group

7

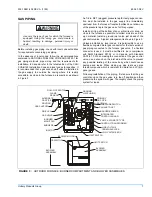

GAS PIPING

Before installing gas piping, check with local code authorities

for requirements concerning gas piping.

In the absence of local codes, follow the recommendations

contained in NATIONAL FUEL GAS CODE ANSI Z223.1 for

gas piping materials, pipe sizing, and the requirements for

installation. In Canada, refer to the latest edition of the CAN/

CGA-B149 Installation Code and local codes for specifics. It

is recommended that a gas cock shutoff valve be installed in

the gas supply line outside the casing where it is readily

accessible, as close to the furnace as is practical, as shown

in Figure 3.

An 1/8 in. NPT (plugged) pressure tap for test gauge connec-

tion must be installed in the gas supply line immediately

upstream from the furnace if local authorities do not allow use

of the pressure tap in the gas valve for this purpose.

Install a dirt leg at the bottom of any vertical riser or drop, as

close to the furnace as possible, to collect moisture and for-

eign material. Install a ground joint union just ahead of the

gas control valve. A typical arrangement is shown in Figure 3.

Unless prohibited by local codes, it is permissible to use a

flexible corrugated metal gas connector for the last section of

gas piping connected to the furnace gas valve. If a flexible

connector is used, it must be certified to be in compliance

with ANSI Standard Z21.24 or, in Canada, with Standard

CAN1-6.10. When making the connection at the gas control

valve, use a wrench on the inlet side of the valve to prevent

any possible twisting of the valve body which could cause

damage and leaks. When making up pipe joints use pipe

thread compound which is resistant to natural and LP (pro-

pane) gases.

Following installation of the piping, first ensure that the gas

control knob on the gas valve is in the off position and then

pressurize the system with gas. Thoroughly check the piping

system for leaks.

Use only the type of gas for which the furnace is

equipped. Using the wrong gas could create a

hazard, resulting in damage, personal injury or

death.

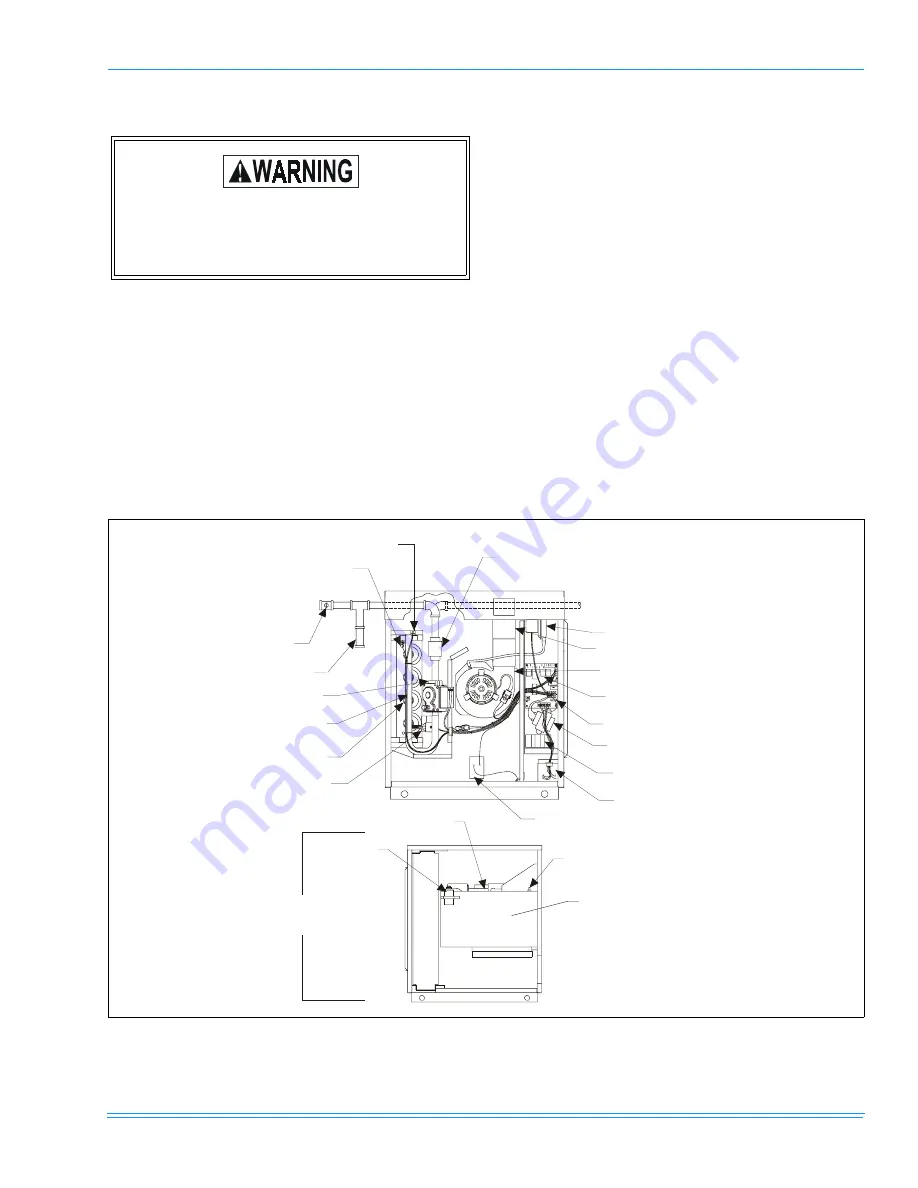

FIGURE 3 :

OUTDOOR FURNACE: BURNER COMPARTMENT AND BLOWER ASSEMBLIES

ROLL-OUT SWITCH

FLAME

SENSOR

ALTERNATE

GAS PIPE

ROUTING

GAS SHUTOFF

DRIP LEG

GAS VALVE

BURNER

MANIFOLD

BURNERS

IGNITOR

LIMIT SWITCH

GROUND

JOINT UNION

PRESSURE SWITCH

PRIMARY

GAS PIPE

ROUTING

EXHAUST DUCT

INDUCER BLOWER

INTEGRATED

CONTROL BOARD

5 AMP. AUTOMATIC TYPE

CONTROL TRANSFORMER

LINE VOLTAGE

TERMINAL BLOCK

LOW VOLTAGE BOX

BLOWER MOTOR

CAPACITOR

LIMIT SWITCH

BLOWER

ASSEMBLY

BLOWER

ASSEMBLY