650.67-N2V

035-15881-402 REV. A (1199)

8

Unitary Products Group

The maximum and minimum gas supply pressure required at

the inlet of the gas control valve is shown on the unit rating

plate. When the furnace is in operation, the inlet pressure

must be within the limits shown.

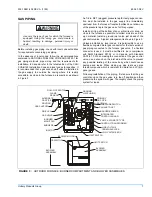

ELECTRICAL WIRING

All internal wiring has been made at the factory. Field wiring

requires only the connection of the line voltage supply wiring,

and low voltage thermostat wiring.

Line voltage supply wiring and control wiring may be brought

into the furnace through either side using the holes provided.

The furnace has been provided with two holes for line voltage

wiring, and one hole for thermostat wiring on each side. The

line voltage wiring plates may be removed, or removed and

reinstalled for different conduit sizes. (See Figures 4 and 5.)

During pressure testing of the gas supply piping

system, observe the following to avoid fire, explo-

sion, asphyxiation, or damage to the appliance.

If test pressure is greater than 1/2 psig (3.48

kPa)(14" w.c.), the furnace and its individual shut-

off valve must be disconnected from the gas sup-

ply system.

Never use an open flame to check for leaks. Fire

or explosion could occur. Since some leak solu-

tions including soap and water may cause corro-

sion or stress cracking, the piping must be rinsed

with water after testing unless it has been deter-

mined that the leak solutions is noncorrosive.

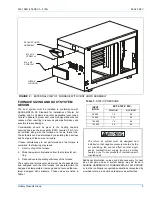

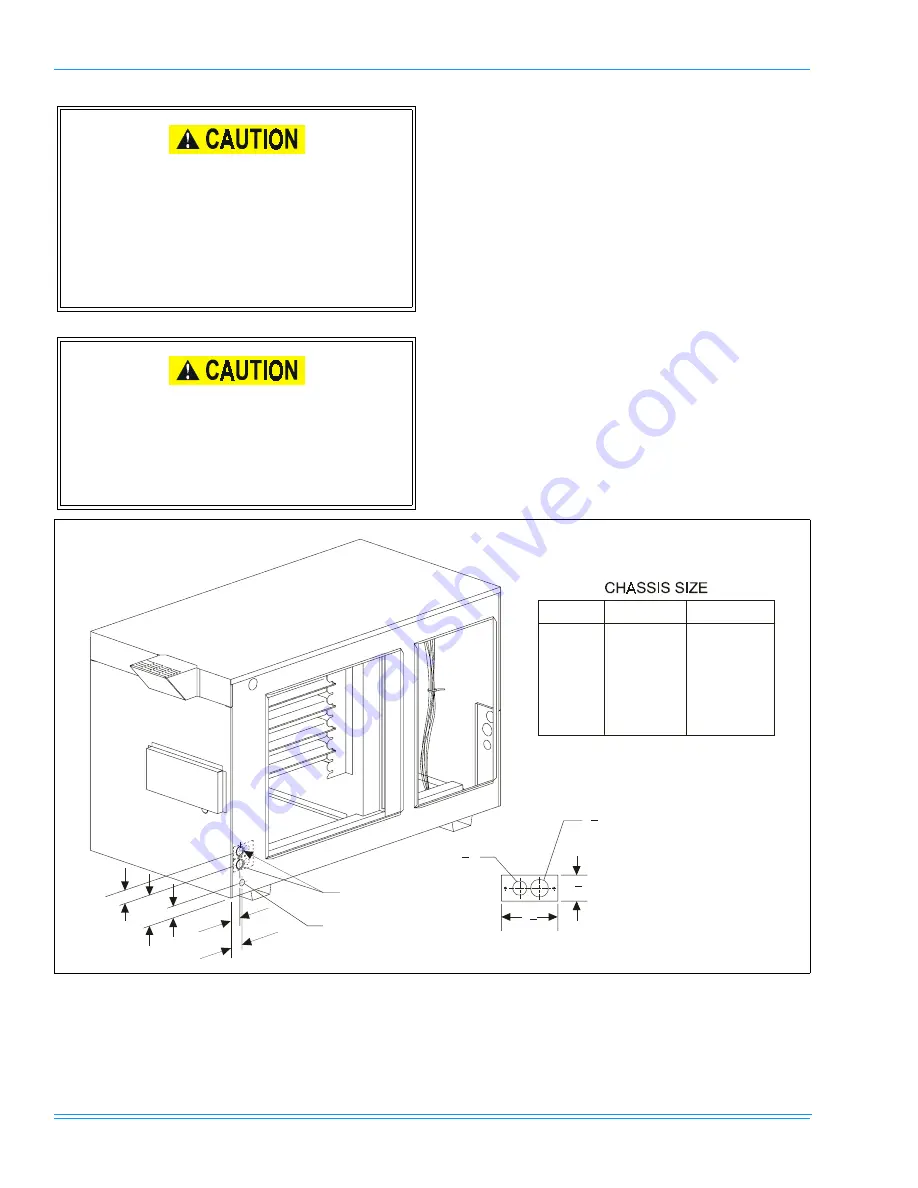

FIGURE 4 :

BASE MODEL FRONT VIEW

A

B

C

D

E

3

9

16

1

5

8

7

8

D

1

3

32

D

SMALL

LARGE

LETTER

A

B

C

D

E

2-1/8”

2-1/8”

2-1/4”

2-31/32”

1-9/16”

1-3/4”

2-1/8”

1-3/4”

4-1/8”

1-9/16”

LINE VOLTAGE

SUPPLY INLETS

7/8 DIA. LOW VOLTAGE

INLET HOLE