035-15881-402 REV. A (1199)

650.67-N2V

Unitary Products Group

9

SERVICE WIRING

Field wiring connections should be made inside the control

box and a suitable strain relief should be used at the point the

wires exit the furnace casing. In order for the electrical con-

trols in the furnace to operate properly, correct electrical

polarity must be observed. Field wiring of the unit should con-

form to local codes or in the absence of local codes with the

National Electrical Code ANSI/NFPA 70. In Canada, field wir-

ing of the unit should conform to local codes or in the

absence of local codes with the Canadian Electrical Code,

Part I, CSA C22.1.

A separate fused circuit from the main electrical panel should

serve only the furnace.

ELECTRICAL GROUNDING

The furnace casing must have an uninterrupted electrical

ground in accordance with the National Electrical Code ANSI/

NFPA 70 or, in Canada, with the Canadian Electrical Code,

Part I, CSA C22.1. DO NOT use gas piping as an electrical

ground.

CONTROL WIRING

The thermostat should be installed in accordance with the

manufacturer's instructions, furnished with the thermostat,

and make connections to the unit as shown on the unit wiring

diagram. It is recommended that size 18 AWG wire be used.

HEAT ANTICIPATOR

If the wall thermostat has an adjustable heat anticipator, the

setting should be.48 amps. If any accessories are to be con-

nected to the furnace, the heat anticipator setting may

change. Use a suitable ammeter to measure the actual antic-

ipator current.

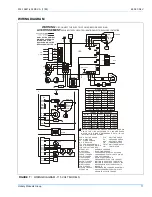

BLOWER MOTOR SPEED SELECTION

These furnaces are equipped with blowers which have multi-

speed direct drive motors.

The blower speed selected is dependent upon the design

and static pressure loss of the duct system. The duct system

external static pressure includes the combined total of the

supply and return ducts and any air conditioning coil if used.

The furnace must be adjusted to operate at or below the

maximum external static (in. W.C.) and within the air temper-

ature rise range as shown on the unit rating plate and in the

specification table.

Dependent upon the conditions in a particular installation, the

blower speeds may need to be changed to give the proper

operation on cooling or heating.

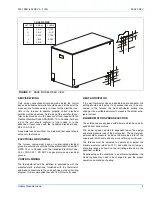

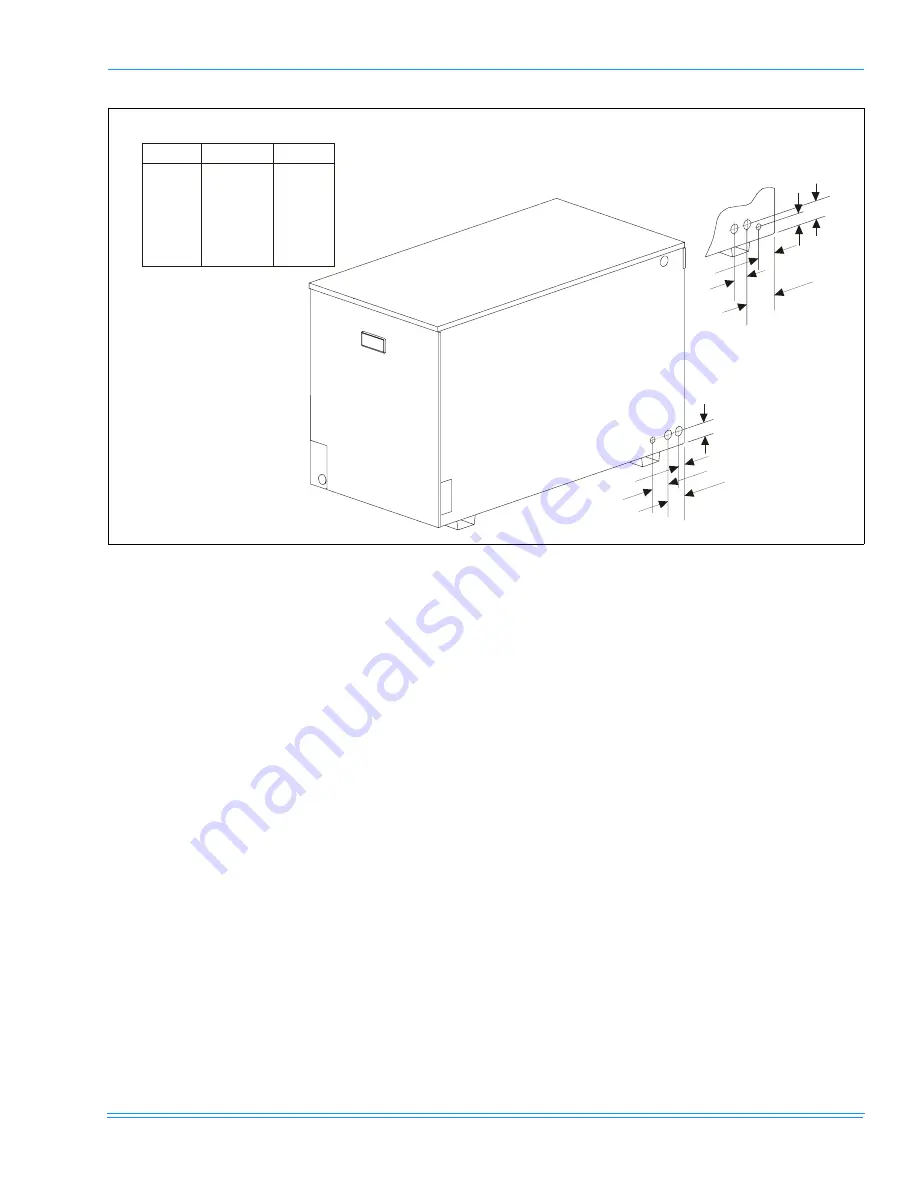

FIGURE 5 :

BASE MODEL REAR VIEW

F

G

H

J

F

H

G

J

K

CHASSIS SIZE

LETTER

SMALL

LARGE

F

G

H

J

K

1-3/4”

3-3/4”

2-3/16”

1-9/16”

2-3/8”

3-1/32”

3-1/4”

1-7/32”

2-3/32”

----