035-17438-001 Rev. A (901)

26

Unitary Products Group

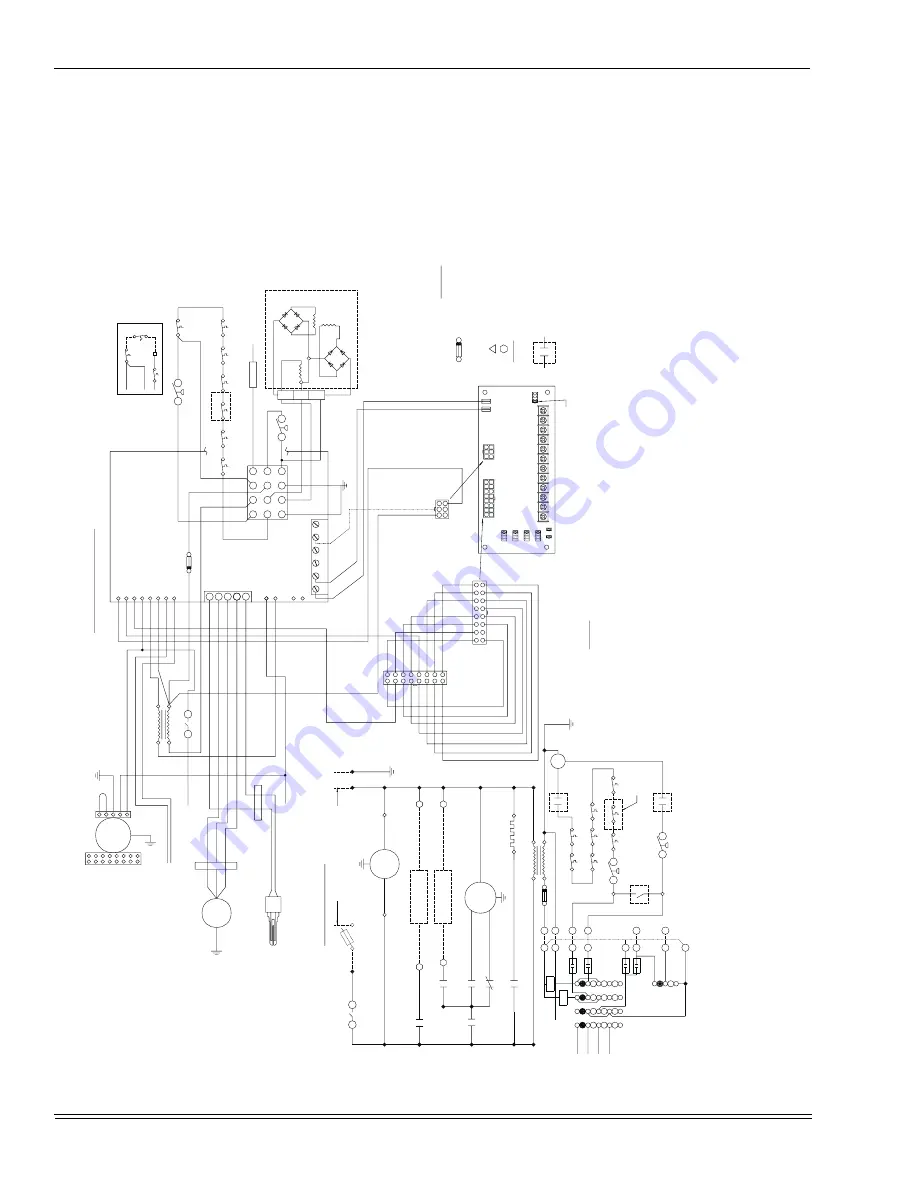

WIRING DIAGRAM

NOTE:

The furnace’s control system depends on correct polarity of the power supply.

X/L

O

C

G

W2

W1

R

Y

Y1

Y2

ADJ

DELAY

HEAT

RED

P6

YEL/BLK

RED

GRN

6

4

3

1

16

8

9

1

16

8

9

1

BLK

BLK

BLK

P7

PRP

YEL

WHT

RED

BLK

WHT

BLK

ORN

BLK

BRN

RED

BRN

YEL

GRN

YEL/BLK

CFM/TIMERBOARD

W1

W2

MINUTESELECT

HUMIDISTAT

HEATPUMP

COOL

HUM

S6

S9

P9

BLU

BLU/WHT

PUR

YEL

WHT

RED

BLK

ORN

BLK

BRN

RED

YEL

GRN

YEL/BLK

BLK

S7

P8/S8

ROS3

FA

N

SWITCH

OFF

AUT

O

COOL

1

COOL

2

HEA

T

2

HEA

T

1

HIGH

LIMIT

HIGH

LIMIT

OFF

COOL

AUT

O

Y2

RC

G

G

RELA

Y

CONT

ACTS

ON

IGNITION

CONTROL

BOARD

C

2LP

NO

6.

MOT

ORS

ARE

INHERENTL

Y

PROTECTED.

5.

PROVIDE

DISCONNECTS

FOR

ALL

POWER

SUPPLIES.

4.

ALL

REPLACEMENT

COMPONENTS

MUST

BE

PROPERL

Y

GROUNDED.

3.

CONNECT

ORS

SUIT

ABLE

FOR

COPPER

CONDUCT

ORS

ONL

Y.

2.

IF

ANY

OF

THE

ORIGINAL

WIRE

AS

SUPPLIED

WITH

THE

FURNACE

MUST

BE

REPLACED,

IT

MUST

BE

REPLACED

WITH

WIRING

MA

TERIAL

HA

VING

A

TEMPERA

TURE

RA

TING

OF

A

T

LEAST

221°F

(105

HA

VING

A

TEMPERA

TURE

RA

TING

OF

A

T

LEAST

221°C).

1.

ALL

FIELD

WIRING

(DENOTED

BY

DASHED

LINES)

PER:

(A)

NA

TIONAL

ELEC.

CODE

(NEC)

AND/OR

(B)

CANADIAN

ELEC.

CODE

(CEC)

AND/OR

(C)

LOCAL

OR

CITY

CODES.

FIELD

CONNECTION

HUM

HUM

EAC

EAC

EAC

HUMIDIFIER

BLOWER MOT

OR

80%

UPFLOW/HORIZONT

AL

DELUXE

FURNACE

-

V

ARIABLE

SPEED

IGNITER

RELA

Y

GV

GRD

N.O.SW

DOOR

SWITCH

ELEMENT

AR

Y

DIAGRAM

ELEMENT

AR

Y

DIAGRAM

POWER

SUPPL

Y

120-1-60

SEE

NOTE

1

GRD

DS

C

NO

COM

120V

24V

SEC

PRI

1T

(40V

A)

R

B

VENT

OR

MOT

OR

IGN

HEA

T

NOTES:

LEGEND

DS

DISCONNECT

SWITCH

GV

GAS

V

AL

VE

IGN

HOT

SURF

ACE

IGNIT

OR

P1/S1

12

PIN

PLUG

&

SOCKET

ON

IGN.

CONTROL

BOARD

P2/S2

5

PIN

PLUG

&

SOCKET

ON

IGN.

CONTROL

BOARD

P3/S3

2

PIN

PLUG

&

SOCKET

A

T

HOT

SURF

ACE

IGNIT

OR

P4/S4

3

PIN

PLUG

&

SOCKET

A

T

INDUCER

MOT

OR

P5/S5

3

PIN

PLUG

&

SOCKET

O

N

VA

LV

E

P6/S6

6

PIN

PLUG

&

SOCKET

ON

CFM/TIMER

BOARD

P7/S7

16

PIN

PLUG

&

SOCKET

FOR

MOT

OR

P8/S8

5

PIN

PLUG

&

SOCKET

ON

ICM

BLOWER

MOT

OR

P9/S9

16

PIN

PLUG

&

SOCKET

ON

CFM/TIMER

BOARD

LS1

PRIMAR

Y

LIMIT

SWITCH

LS2,3

AUXILAR

Y

LIMIT

SWITCH

ON

BLOWER

DECK

ROS1

ROLL

OUT

SWITCH

LEFT

SIDE

ROS2

ROLL

OUT

SWITCH

RIGHT

SIDE

ROS3

ROLL

OUT

SWITCH

T

O

P

MIDDLE

(2-5

CELL)

T

O

P

RIGHT

(5

&

7

CELL)

ROS4

ROLL

OUT

SWITCH

T

O

P

LEFT

(6

&

7

CELL

ONL

Y)

SS1

SPILL

SWITCH

(CHIMNEY

KIT)

-

CAUTION

-

-

CAUTION

-

OPEN

ALL

DISCONNECTS

BEFORE

SER

VICING

THIS

UNIT

FUSE

1LP

PRESSURE

SW

,

FIRST

ST

AGE

2LP

PRESSURE

SW

,

SECOND

ST

AGE

1T

TRANSFORMER,

40V

A

24V

CONNECTION

ROOM

THERMOST

AT

F

ACT

OR

Y

WIRING

AND

DEVICES

-----

FIELD

WIRING

AND

DEVICES

3A

1ST

S

T

AGE

2ND

S

T

AGE

R

C

W1

W2

W1

W2

Y1

Y

LS2

LS3

ROS2

ROS1

ROS4

LS1

HIGH

LOW

GRN

GRD

ICM

WHT

ROS3

P

5

\

S

5

2S

T

A

G

E

GAS

V

A

LV

E

MAIN

120V

AC.

LINE

BLK

BLK

EAC

HUM

2

W

1

B

G

R

Y

W

HUM

EAC

N1

E2

U0

T

RV

AA

LC

H

O

T

1

2

0

V

A

C

C

NO

BLU

BLK

WHT

BLK

ORN

WHT

BLU

WHT

BLK

CIRC

IN

GRD

GRN

GRD

XFMR

NO

C

1LP

CONNECTION

DIAGRAM

RED

P1/S1

HOT

SURF

ACE

IGNITER

WHT

WHT

BLK

WHT

BLK

1

2

1

3

P3/S3

P4/S4

BRN

GRN

GRN

FLAME

SENSOR

BLU

2LP

120

VA

C

120V

COM

24V

SEC

PRI

DOOR

N.O.SW

C

NO

VENT

OR

MOT

OR

GRN

MOT

OR

BLOWER

WHT

BRN

BLK

LINE

1

2

3

4

5

6

7

8

9

10

11

12

PRP

P2/S2

XFMR

LINE

4

3

2

1

HEA

T

H

I

HEA

T

L

O

COOL

5

BLK

2

BRN

RED

BRN

RED

WHT

BLK

RED

WHT

BRN

3A

ROS1

ROS2

LS3

LS2

RED

M

C

HI

ROS4

WHT

120

VA

C

YEL

LS1

RED

YEL

YEL

YEL

BRN

GRD

BRN

BRN

BRN

WHT

RED

BLK

BLK

D

O

T

NO

C

1LP

ICM

YEL/BLK

RED

BLU/WHT

BLU

BLU

ROS3

LS1

WHT

SS1

RED

SEE

NOTE

8

7.

SS1

IN

SERIES

WITH

LS1

AND

ROS3

(FIELD

INST

ALLED).

SS1

SEE NOTE

8

GRN

TIMEROFF

8.

TIMER

JUMPER

MUST

BE

IN

THE

OFF

POSITION

WHEN

USING

A

TWO

ST

AGE

THERMOST

AT

.

SEE

NOTE

9