268894-UIM-A-0407

Unitary Products Group

5

Table 2 is a guide for determining whether the rectangular duct system

that the furnace is being connected to be of sufficient size for proper fur-

nace operation.

Use the Example below to help you in calculating the duct area to deter-

mine whether the ducts have sufficient area so that the furnace oper-

ates at the specified external static pressure and within the air

temperature rise specified on the nameplate.

The following are general duct sizing guidelines that may not serve to

requirements of every application.

Example: The furnace input is 80,000 BTUH with 1,200 CFM blower

requirement. The recommended duct area is 216 sq. in, there are two 8

x 12 rectangular ducts attached to the plenum and there are two 7 inch

round ducts attached to the furnace.

1.

Take 8 x 12, which equals 96 sq. in. X 2, which equals 192 square

inches then go to round duct size located in Table 3.

2.

The square inch area for 7 inch round ducts is 38.4 sq. in. x 2 =

76.8 square inches.

3.

Then take the 192 square inch from the rectangular duct and add it

to the 76.8 sq. in. of round duct. The total square inch of duct

attached to the furnace supply plenum is 268.8 total square

inches. This exceeds the recommended 216 square inch of duct.

In this example, the duct system attached to the plenum has a sufficient

area so that the furnace operates at the specified external static pres-

sure and within the air temperature rise specified on the nameplate,

providing the return duct is properly sized as well.

1.

The Air Temperature Rise is determined by subtracting the Return

Air Temperature Reading from the Supply Air Temperature Read-

ing.

2.

The External Static Pressure is determined by adding the Supply

Duct Static Pressure reading to the Return Duct Static Pressure

reading and adding the pressure drop across any applied a-coil

and return air filter.

Tables 2 and 3 are to be used as a guide only to help the installer deter-

mine if the duct sizes are large enough to obtain the proper air flow

(CFM) through the furnace. Tables 2 and 3 ARE NOT to be used to

design ductwork for the building where the furnace is being installed.

There are several variables associated with proper duct sizing that are

not included in the tables. To properly design the ductwork for the build-

ing, refer to the ASHRAE Fundamentals Handbook, chapter on “DUCT

DESIGN” or a company that specializes in Residential and Modular

Home duct designs.

IMPORTANT:

If the supply air duct is being connected to the furnace

without the use of an accessory duct connector, then a transition duct

must be installed with flanges or tabs that are securely attached and

sealed to the supply air duct and to the base of the furnace. The transi-

tion duct must have insulation between the transition duct and any com-

bustible material.

The transition duct must be the same dimensional size as the rectangu-

lar opening in the base of the furnace.

TABLE 2:

Minimum Duct Sizing For Proper Airflow

Input/Cabinet

Airflow

Return

1

Rectangular

2

Round

2

Supply

3

Rectangular

2

Round

2

BTU/H (kW)

CFM (m³)

In² (cm²)

in. x in. (cm x cm)

in. (cm) dia.

In² (cm²)

in. x in. (cm x cm)

in. (cm) dia.

40/A (11.7)

1200 (34.0)

280 (1806)

14 x 20 (35.6 x 50.8)

18 (45.7)

216 (1394)

12 x 18 (30.5 x 45.7)

16 (40.6)

60/A (17.6)

1200 (34.0)

280 (1806)

14 x 20 (35.6 x 50.8)

18 (45.7)

216 (1394)

12 x 18 (30.5 x 45.7)

16 (40.6)

80/A (23.4)

1200 (34.0)

280 (1806)

14 x 20 (35.6 x 50.8)

18 (45.7)

216 (1394)

12 x 18 (30.5 x 45.7)

16 (40.6)

80/B (23.4)

1600 (45.3)

360 (2322)

18 x 20 (45.7 x 50.8)

22 (55.8)

280 (1806)

14 x 20 (35.6 x 50.8)

18 (45.7)

80/C (23.4)

1600 (45.3)

360 (2322)

18 x 20 (45.7 x 50.8)

22 (55.8)

280 (1806)

14 x 20 (35.6 x 50.8)

18 (45.7)

100/B (29.3)

1200 (34.0)

280 (1806)

14 x 20 (35.6 x 50.8)

18 (45.7)

216 (1394)

12 x 18 (30.5 x 45.7)

16 (40.6)

100/C (29.3)

1600 (45.3)

360 (2322)

18 x 20 (45.7 x 50.8)

22 (55.8)

280 (1806)

14 x 20 (35.6 x 50.8)

18 (45.7)

100/C (29.3)

2000 (56.6)

440 (2834)

20 x 22 (50.8 x 55.8)

24 (60.9)

390 (2516)

16 x 22 (40.6 x 55.8)

22 (55.8)

115/C (33.7)

1600 (45.3)

360 (2322)

18 x 20 (45.7 x 50.8)

22 (55.8)

280 (1806)

14 x 20 (35.6 x 50.8)

18 (45.7)

115/C (33.7)

2000 (56.6)

440 (2834)

20 x 22 (50.8 x 55.8)

24 (60.9)

390 (2516)

16 x 22 (40.6 x 55.8)

22 (55.8)

130/D (38.1)

2000 (56.6)

440 (2834)

20 x 22 (50.8 x 55.8)

24 (60.9)

390 (2516)

16 x 22 (40.6 x 55.8)

22 (55.8)

NOTE: This chart does not replace proper duct sizing calculations or take into account static pressure drop for run length and fittings. Watch out for the temperature rise and static pressures.

1.

Maximum return air velocity in rigid duct @ 700

feet per minute (213 m/min).

2.

Example return main trunk duct minimum dimensions.

3.

Maximum supply air velocity in rigid duct @ 900

feet per minute (274 m/min).

TABLE 3:

Round Duct Size

Round Duct Size

Calculated Area For Each Round Duct Size

inches (cm)

Sq.in (cm

2

)

5 (13)

19.6 (126)

6 (15)

28.2 (182)

7 (18)

38.4 (248)

8 (20)

50.2 (324)

9 (23)

63.6 (410)

10 (25)

78.5 (506)

11 (28)

95 (613)

12 (30)

113.1 (730)

13 (33)

132.7 (856)

14 (36)

153.9 (993)

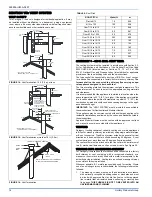

FIGURE 1:

Combustible Floor Base Accessory

DOWNFLOW

FURNACE

WARM AIR PLENUM

WITH 1” FLANGES

FIBERGLASS

INSULATION

FIBERGLASS TAPE

UNDER FLANGE

COMBUSTIBLE FLOOR

BASE ACCESSORY