66339-BIM-C-0206

Unitary Products Group

11

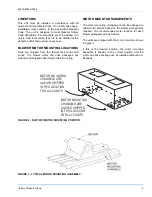

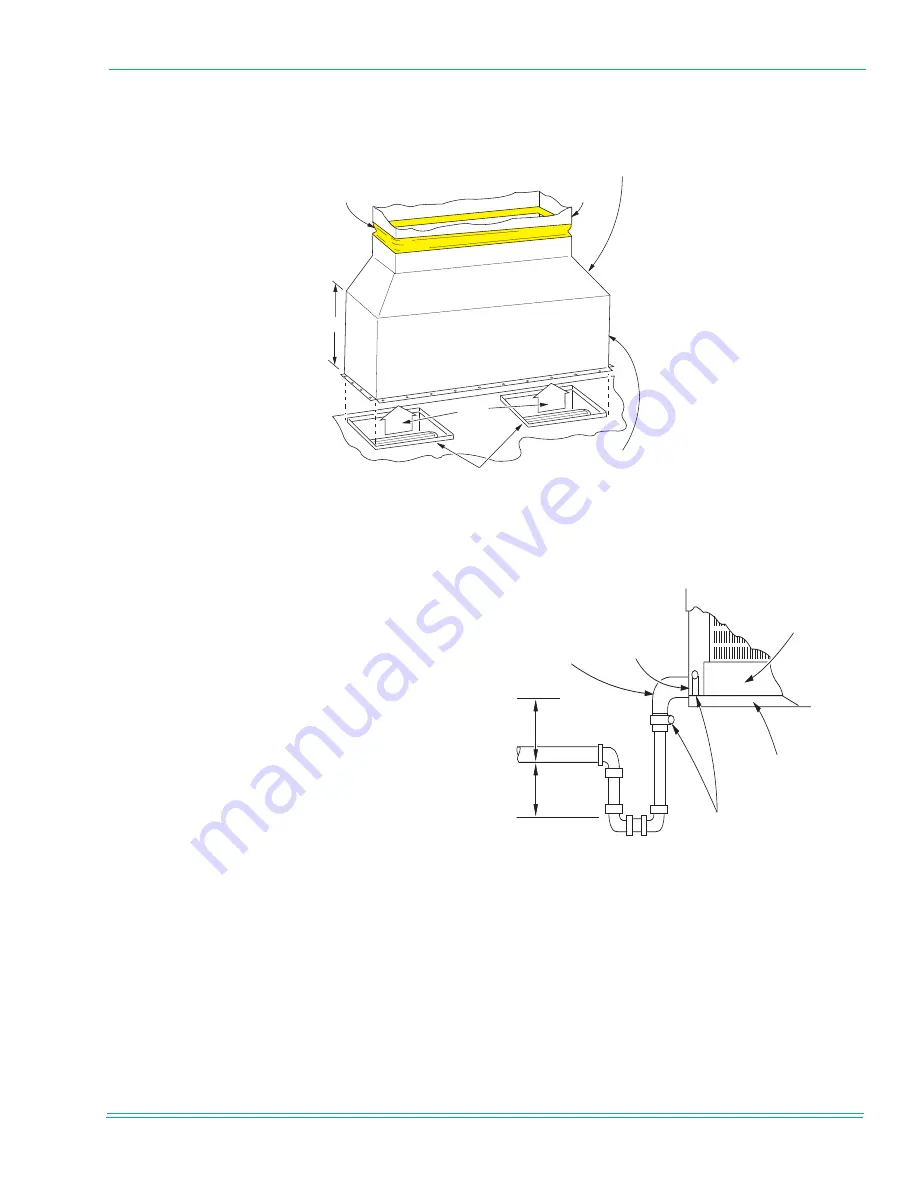

RETURN AIR DUCT ANGLES

Return air duct angles are shipped turned in. They are

intended to be unscrewed and turned for connection of

ductwork.

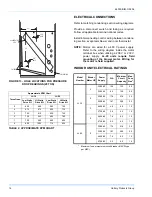

DRAIN CONNECTIONS

All drain lines MUST be trapped and located so they

will not be exposed to freezing temperatures.

The LL-20 evaporator blower has 7/8” OD steel con-

densate stub at each end of a single drain pan. Both

ends are closed with plastic caps. A plastic ell (field

supplied) can be used. Attach the ell to the desired end

and run a full size 7/8” drain line to the nearest drain

facility. Seal the cap at the unused end with suitable

mastic. The LL-15 evaporator has one 7/8” OD drain

connection through the right side of the cabinet.

Drain piping should be constructed as shown in figure

9. The 5-inch dimension is intended to exceed the neg-

ative static pressure developed by the supply air blow-

ers. If it does not, the condensate will not drain properly

and may overflow the drain pan. The trap must be at

least 2 1/2 inches deep to maintain a water seal under

all operating conditions, especially when the blowers

are starting.

REFRIGERANT MAINS

Hard drawn copper tubing should be used where no

appreciable amount of bending around pipes or other

obstructions is necessary. Use long radius ells wher-

ever possible. If soft copper is used, care should be

taken to avoid sharp bends that may cause a restric-

tion.

FIGURE 10 - SUGGESTED METHOD FOR CONNECTING DUCTWORK

24"

AIR

OUTLET

BLOWER

GASKETS

(BY INSTALLER)

FLANGED DUCT

CONNECTION

(FIELD

FABRICATED)

NON-FLAMMABLE

COLLAR

DUCT

TRANSITION

DUCT

FIGURE 11 - RECOMMENDED DRAIN PIPING