66339-BIM-C-0206

Unitary Products Group

13

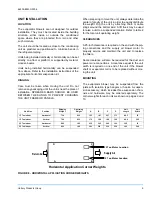

Each unit has a low static and a high static option. The

15 Ton unit offers a 3 hp motor and sheave combina-

tion for the low static option and a 5 hp motor and

sheave combination for the high static option. The 20

Ton offers a 5 hp motor to be used with either the low

or high static sheaves.

Each motor pulley has:

1.

A threaded barrel with two flats (or notched

recesses 180º apart).

2.

A movable flange with one set screw.

After the movable flange has been rotated to the

proper number of turns open, the set screw should be

tightened against the flat on the barrel to lock the mov-

able flange in place. If the pulley includes a locking col-

lar, the locking collar must be loosened to adjust the

setting of the movable flange.

Note the following:

1.

The supply of air CFM must be within the limita-

tions shown in the tables. Be sure not to over amp

the motor.

2.

All pulleys can be adjusted in 1/2 turn increments.

3.

The tension on the belt(s) should be adjusted for a

deflection of 3/16” per foot of belt span with an

applied force of 2 to 3 pounds.

Once the supply air blower motor is operating, adjust

the resistances in both the supply and the return duct

system to balance the air distribution throughout the

conditioned space. The job specification may require

that the balancing be done by someone other than the

equipment installer.

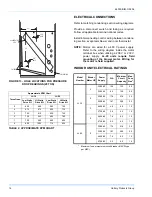

To check the supply air CFM after the initial balancing

has been completed:

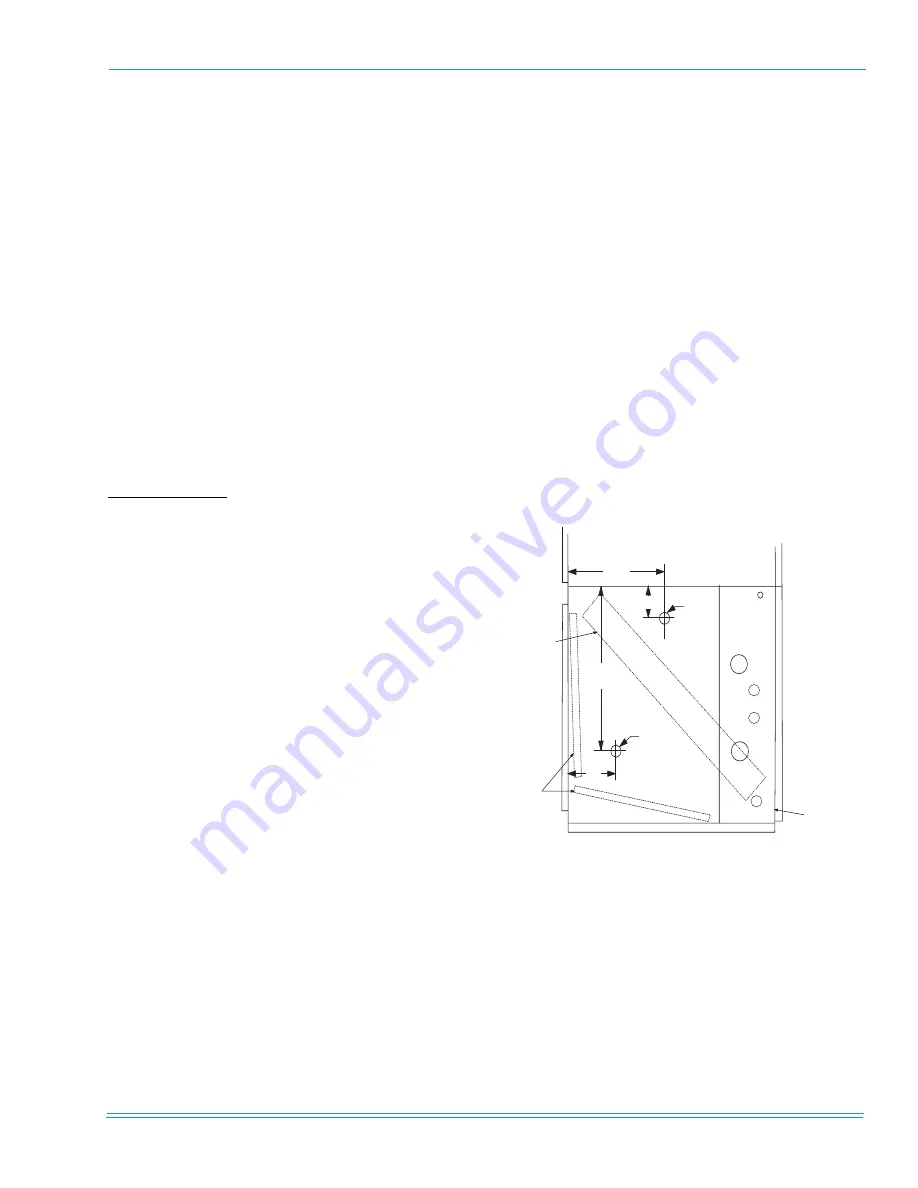

1.

Drill two 5/16” holes in the side panel as shown in

figure 10 for the 15 Ton or figure 11 for the 20 Ton.

2.

Insert at least 6” of 1/4” tubing into each of these

holes for sufficient penetration into the air flow on

either side of the indoor coil.

NOTE:

The tubes must be inserted and held in a posi-

tion perpendicular to the air flow so that veloc-

ity pressure will not affect the static pressure

reading.

3.

Using an inclined manometer, determine the pres-

sure drop across a dry coil.

4.

Consult the appropriate coil pressure drop chart to

determine the CFM.

5.

After the readings have been obtained, remove the

tubes and seal up the drilled holes in the side

panel. Dot plugs (P/N 029-13880-000) are avail-

able through Source One parts.

FIGURE 12 - HOLE LOCATIONS FOR PRESSURE

DROP READINGS (15 TON)

5/16"

HOLE

5/16"

HOLE

18"

7"

22"

10"

EVAPORATOR

COIL

FILTERS

COIL SECTION