66339-BIM-C-0206

Unitary Products Group

9

UNIT INSTALLATION

LOCATION

The evaporator blowers are not designed for outdoor

installation. They must be located inside the building

structure, either inside or outside the conditioned

space where they are protected from rain and other

such moisture.

The unit should be located as close to the condensing

unit as practical and positioned to minimize bends in

the refrigerant piping.

Units being installed vertically or horizontally can be set

directly on a floor or platform, or supported by metal or

wooden beams.

Units being installed horizontally can be suspended

from above. Refer to the installation instructions of the

appropriate horizontal suspension kit.

RIGGING

Care must be taken when moving the unit. Do not

remove any packaging until the unit is near the place of

installation. SPREADER BARS SHOULD BE USED

BETWEEN THE SLINGS TO PREVENT CRUSHING

THE UNIT FRAME OR PANELS.

When preparing to move the unit, always determine the

center of gravity of the unit in order to equally distribute

the weight. Rig the unit by attaching chain or cable

slings around the bottom skid. A lift truck may be used

to raise a unit to a suspended location. Refer to table 2

for the total unit operating weight.

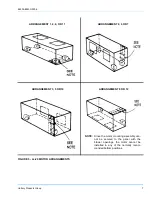

CLEARANCES

A 25-inch clearance is required on the end with the pip-

ing connections and the supply air blower motor to

properly service and maintain the unit and to replace

the filters.

Some clearance will also be required for the duct and

power wire connections. A clearance equal to the unit

width is required on one end of the unit if the blower

shaft or evaporator coil is to be replaced without mov-

ing the unit.

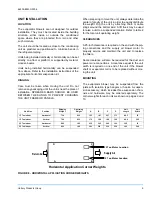

MOUNTING

The evaporator blower may be suspended from the

joists with isolation type hangers or hooks. A suspen-

sion accessory, which includes three suspension chan-

nels and hardware, may be ordered separately. The

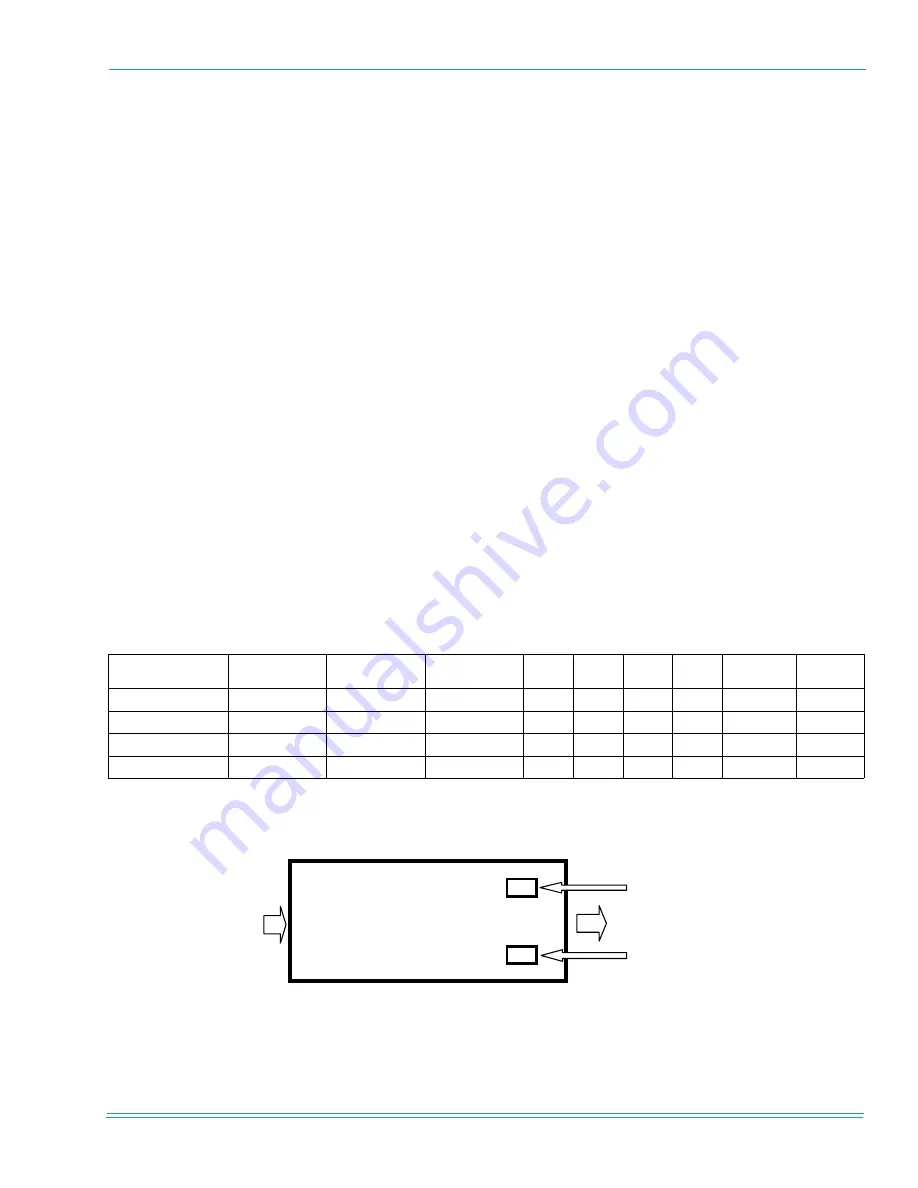

corner weights for each unit are shown on pages 9 and

10.

Unit Size

Position

Shipping

Weight

Operating

Weight

A

B

C

D

Unit

Length

Unit

Width

15 Ton Indoor

Horizontal

720

830

155

187

207

171

89.5

59

15 Ton Indoor

Vertical

720

830

172

194

188

166

89.5

29.5

20 Ton Indoor

Horizontal

990

1115

230

345

249

166

100

74

20 Ton Indoor

Vertical

990

1115

263

238

232

256

100

36.5

FIGURE 8 - HORIZONTAL APPLICATION CORNER WEIGHTS

D

C

20 Ton Motor Location

Return Air

A

B

Horizontal Application Corner Weights

15 Ton Motor Location

Supply Air