Subject to change without notice. Printed in U.S.A.

035-14446-000 Rev. B (1002)

Copyright

©

by York International Corp. 2002. All rights reserved.

Supersedes: 035-14446-000 Rev. A (0301)

Unitary

5005 Norman

Product

York

OK

Group

Drive

73069

6.

Turn unit electrical disconnect switch to ON. The com-

bustion blower should start and the hot surface igniter

should start glowing.

7.

After air has been purged from the gas supply line, igni-

tion should occur. Shortly after ignition, the manifold and

gas inlet pressures can be checked on the manometers.

Main burner ignition may be delayed on the first ignition

cycle due to air in the gas manifold.

8.

Adjust manifold pressure to specifications shown in

Table 6. This setting will result in an input which is prop-

erly derated for your altitude. Supply gas must be within

the range shown in Table 6. If required, adjust the incom-

ing regulator spring so that the pressure falls within the

range.

9.

Observe several ignition cycles. All main burners must

ignite without delayed ignition or burning at the orifices. If

delayed ignition is observed, verify that the igniter is

properly mounted (not loose or crooked on bracket, and

that bracket screws are not loose).

10. If burning at the orifices, excessive yellow tipping, or

excessive noise is observed during any phase of main

burner operation, correct unit operation.

11. With the main burners ignited, check for gas leaks,

especially in the following locations: gas valve inlet and

outlet connections, manifold union in the burner compart-

ment, and main burner orifices where they thread into

the manifold. Repair any leaks found and recheck.

12. Operate the furnace for 15 minutes and measure the

supply and return air temperatures. Verify that the tem-

perature rise (supply air - return air rise) is within the

allowable range. See the unit data plate for the minimum/

maximum allowable temperature rise. If the measured

rise is in excess of the maximum shown on the data

plate, a higher blower speed must be selected. See the

unit wiring diagram to make this change.

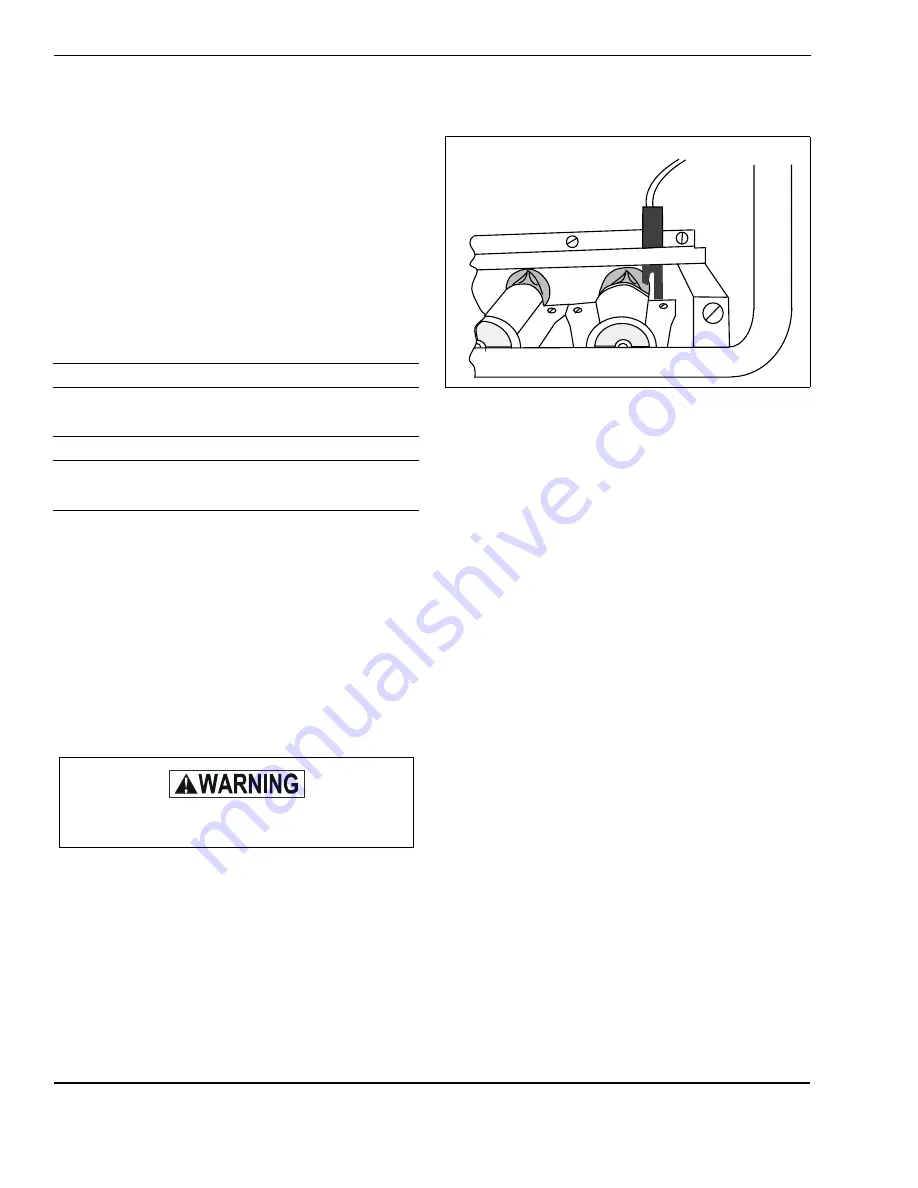

13. During unit operation, the main burner appearance and

igniter location should be as shown below:

14. With the main burners off, disconnect the manometers

and replace the plugs. Check for gas leakage at the

plugs.

15. Replace all access panels.

LABELS

1.

Remove label 035-11635-000 from the shipping box.

Check the Normal to High Altitude.

NOTE:

If the unit has been converted from natural gas to pro-

pane (LP), place the new label over the existing label and fill

in the appropriate information.

2.

Under "Rating After Conversion", write in the following:

a.

Orifice size, as stamped on the orifice

b.

Maximum inlet pressure

c.

Minimum inlet pressure

d.

Manifold pressure for both low and high inputs

e.

Input ratings, same as on the rating plate

f.

Outlet ratings, same as on the rating plate

3.

Under "Changes After Conversion", write in the follow-

ing:

a.

Kit number, located on the outside of the box.

b.

Unit model

c.

Stamp or write in the name of the organization mak-

ing conversion, address, city, state, month and year.

4.

Remove label backing and affix label adjacent to the Rat-

ing Plate.

5.

On propane (LP) conversions, affix the corresponding

gas valve label (provided in the conversion kit) to the

valve.

Table 6:

GAS PRESSURES

NATURAL GAS

Inlet Gas Pressure Must Be

at 4.5” - 13.9” WC at Furnace

Set Manifold Pressure at 3.5” WC

PROPANE (LP) GAS

Inlet Gas Pressure Must Be

at 11” - 13.9” WC at Furnace

Set Manifold Pressure at 10” WC

Do not use an open flame or any source of ignition

to check for leaks.

FIGURE 1:

Proper Burner Flame Appearance

BLUE CONE PORTION OF

FLAME SHOULD ENTER

HEAT EXCHANGER TUBE