035-19656-003 Rev. A (1004)

24

Unitary Products Group

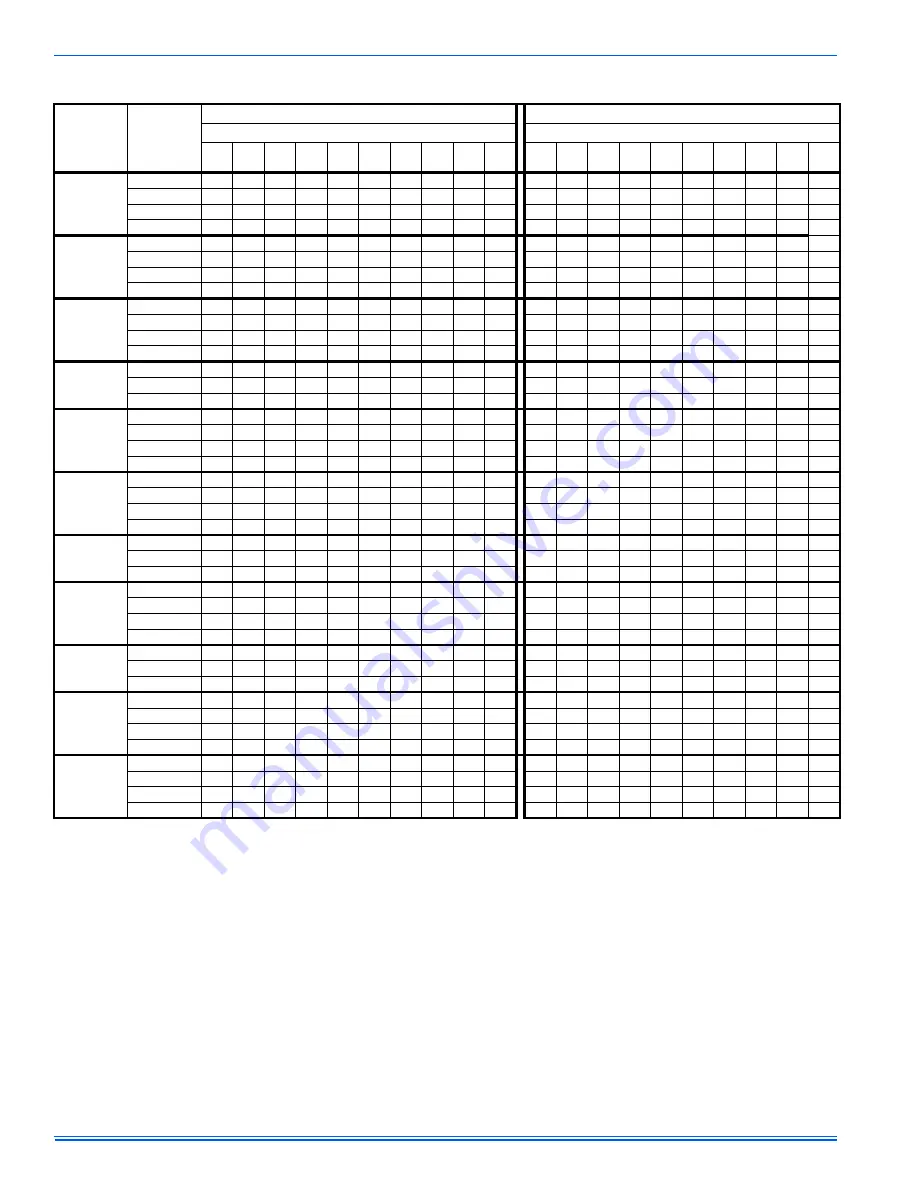

NOTES

1. Airflow expressed in standard cubic feet per minute (CFM).

2. Return air is through side opposite motor (left side).

3. Motor voltage at 115 V.

* Input / CFM / Cabinet Width (A=14-1/2, B=17-1/2, C=21, D=24-1/2)

† Indicates model available in LoNOx.

TABLE 18:

Blower Performance CFM - Upflow (without filter) - Left Side Return

MODELS

Input /

CFM

Speed

Single Stage Left Side Airflow Data (SCFM)

Single Stage Left Side Airflow Data

(cm/m)

Ext. Static Pressure (in. H2O)

Ext. Static Pressure (kPa)

0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1.0

0.02

5

0.05

0

0.07

5

0.10

0

0.12

5

0.14

9

0.17

4

0.19

9

0.22

4

0.24

9

40/1200/A

†

High

1810 1730 1660 1570 1480 1390 1300 1200 1090 930 51.3 49.0 47.0 44.5 41.9 39.4 36.8 34.0 30.9 26.3

Medium

High 1390 1390 1350 1320 1270 1210 1150 1080 970 790 39.4 39.4 38.2 37.4 36.0 34.3 32.6 30.6 27.5 22.4

Medium

Low 1120 1120 1120 1110 1080 1080 1020 930 830 690 31.7 31.7 31.7 31.4 30.6 30.6 28.9 26.3 23.5 19.5

Low

880 910 920 920 910 870 820 740 650 510 24.9 25.8 26.1 26.1 25.8 24.6 23.2 21.0 18.4 14.4

60/1200/A

†

High

1770 1690 1630 1560 1490 1390 1290 1190 1050 920 50.1 47.9 46.2 44.2 42.2 39.4 36.5 33.7 29.7 26.1

Medium

High 1400 1380 1350 1320 1280 1230 1160 1060 930 780 39.6 39.1 38.2 37.4 36.2 34.8 32.8 30.0 26.3 22.1

Medium

Low 1120 1130 1150 1130 1120 1080 1000 950 790 630 31.7 32.0 32.6 32.0 31.7 30.6 28.3 26.9 22.4 17.8

Low

880 900 900 900 880 850 790 730 660 530 24.9 25.5 25.5 25.5 24.9 24.1 22.4 20.7 18.7 15.0

80/1200/A

†

High

1790 1720 1670 1590 1530 1450 1350 1260 1140 1000 50.7 48.7 47.3 45.0 43.3 41.1 38.2 35.7 32.3 28.3

Medium

High 1420 1370 1350 1320 1280 1230 1170 1090 990 840 40.2 38.8 38.2 37.4 36.2 34.8 33.1 30.9 28.0 23.8

Medium

Low 1080 1120 1110 1100 1080 1040 1000 920 820 690 30.6 31.7 31.4 31.1 30.6 29.4 28.3 26.1 23.2 19.5

Low

N/A 900 900 890 870 850 800 730 670 560 N/A 25.5 25.5 25.2 24.6 24.1 22.7 20.7 19.0 15.9

80/1600/B

†

High

2000 1960 1930 1900 1800 1760 1710 1640 1550 1460 56.6 55.5 54.7 53.8 51.0 49.8 48.4 46.4 43.9 41.3

Medium 1440 1440 1430 1420 1400 1380 1340 1300 1220 1150 40.8 40.8 40.5 40.2 39.6 39.1 37.9 36.8 34.5 32.6

Low

1220 1230 1230 1230 1200 1190 1170 1160 1110 1050 34.5 34.8 34.8 34.8 34.0 33.7 33.1 32.8 31.4 29.7

80/2200/C

†

High

2710 2640 2560 2480 2360 2260 2160 2010 1860 1650 76.7 74.8 72.5 70.2 66.8 64.0 61.2 56.9 52.7 46.7

Medium

High 2110 2110 2070 2030 1980 1910 1850 1710 1570 1300 59.7 59.7 58.6 57.5 56.1 54.1 52.4 48.4 44.5 36.8

Medium

Low 1690 1690 1650 1610 1540 1480 1410 1280 1170 1030 47.9 47.9 46.7 45.6 43.6 41.9 39.9 36.2 33.1 29.2

Low

1350 1330 1310 1290 1260 1220 1150 1050 970 860 38.2 37.7 37.1 36.5 35.7 34.5 32.6 29.7 27.5 24.4

100/1200/B

†

High

1780 1710 1640 1560 1490 1390 1290 1180 1030 820 50.4 48.4 46.4 44.2 42.2 39.4 36.5 33.4 29.2 23.2

Medium

High 1430 1410 1370 1340 1280 1220 1140 1040 890 730 40.5 39.9 38.8 37.9 36.2 34.5 32.3 29.4 25.2 20.7

Medium

Low 1140 1170 1150 1120 1080 1040 970 890 760 630 32.3 33.1 32.6 31.7 30.6 29.4 27.5 25.2 21.5 17.8

Low

920 940 950 940 920 890 850 770 660 560 26.1 26.6 26.9 26.6 26.1 25.2 24.1 21.8 18.7 15.9

100/1600/B

†

High

1950 1890 1840 1790 1730 1660 1570 1480 1390 1300 55.2 53.5 52.1 50.7 49.0 47.0 44.5 41.9 39.4 36.8

Medium 1440 1420 1400 1390 1350 1320 1270 1210 1150 1060 40.8 40.2 39.6 39.4 38.2 37.4 36.0 34.3 32.6 30.0

Low

1230 1210 1190 1180 1150 1130 1090 1050 990 920 34.8 34.3 33.7 33.4 32.6 32.0 30.9 29.7 28.0 26.1

100/2000/C

†

High

2770 2670 2610 2540 2450 2340 2210 2070 1890 1730 78.4 75.6 73.9 71.9 69.4 66.3 62.6 58.6 53.5 49.0

Medium High 2120 2060 2030 2000 1950 1880 1810 1720 1580 1370 60.0 58.3 57.5 56.6 55.2 53.2 51.3 48.7 44.7 38.8

Medium Low 1690 1660 1630 1610 1560 1490 1420 1350 1240 1070 47.9 47.0 46.2 45.6 44.2 42.2 40.2 38.2 35.1 30.3

Low

1390 1370 1330 1290 1250 1200 1120 1010 910 850 39.4 38.8 37.7 36.5 35.4 34.0 31.7 28.6 25.8 24.1

115/1600/C

High

2160 2070 1990 1900 1800 1690 1580 1430 1260 1000 61.2 58.6 56.4 53.8 51.0 47.9 44.7 40.5 35.7 28.3

Medium 1760 1720 1690 1630 1560 1480 1390 1250 1080 890 49.8 48.7 47.9 46.2 44.2 41.9 39.4 35.4 30.6 25.2

Low

1510 1490 1470 1440 1380 1300 1210 1110 950 780 42.8 42.2 41.6 40.8 39.1 36.8 34.3 31.4 26.9 22.1

115/2000/C

†

High

2740 2650 2560 2480 2380 2280 2170 1990 1840 1650 77.6 75.0 72.5 70.2 67.4 64.6 61.4 56.4 52.1 46.7

Medium High 2120 2090 2040 2000 1940 1870 1780 1680 1550 1370 60.0 59.2 57.8 56.6 54.9 53.0 50.4 47.6 43.9 38.8

Medium

Low 1690 1670 1650 1610 1560 1510 1440 1310 1160 1030 47.9 47.3 46.7 45.6 44.2 42.8 40.8 37.1 32.8 29.2

Low

1390 1360 1330 1300 1250 1190 1100 1020 940 840 39.4 38.5 37.7 36.8 35.4 33.7 31.1 28.9 26.6 23.8

130/2000/D

†

High

2680 2600 2520 2410 2300 2180 2050 1910 1730 1550 75.9 73.6 71.4 68.2 65.1 61.7 58.0 54.1 49.0 43.9

Medium

High 2140 2110 2070 1990 1930 1850 1770 1670 1530 1370 60.6 59.7 58.6 56.4 54.7 52.4 50.1 47.3 43.3 38.8

Medium Low 1660 1640 1620 1570 1530 1470 1400 1310 1220 1090 47.0 46.4 45.9 44.5 43.3 41.6 39.6 37.1 34.5 30.9

Low

1370 1350 1320 1290 1240 1190 1140 1040 930 860 38.8 38.2 37.4 36.5 35.1 33.7 32.3 29.4 26.3 24.4