CHAPTER 1: DESCRIPTION

HF25D DC RESISTANCE WELDING SYSTEM

1-2

990-333

•

You can program the Control from the front

panel, using simplified key clusters and on-

screen data fields. A

MAIN MENU

screen

allows you select all of the system setup

options for working with inputs from

external equipment.

<MAIN MENU>

1.

SETUP

5.

COMMUNICATION

2. WELD COUNTER

6. RELAY

3. COPY A SCHEDULE

7. CALIBRATION

4. SYSTEM SECURITY

8. RESET TO

DEFAULTS

NUMBER Select an item

•

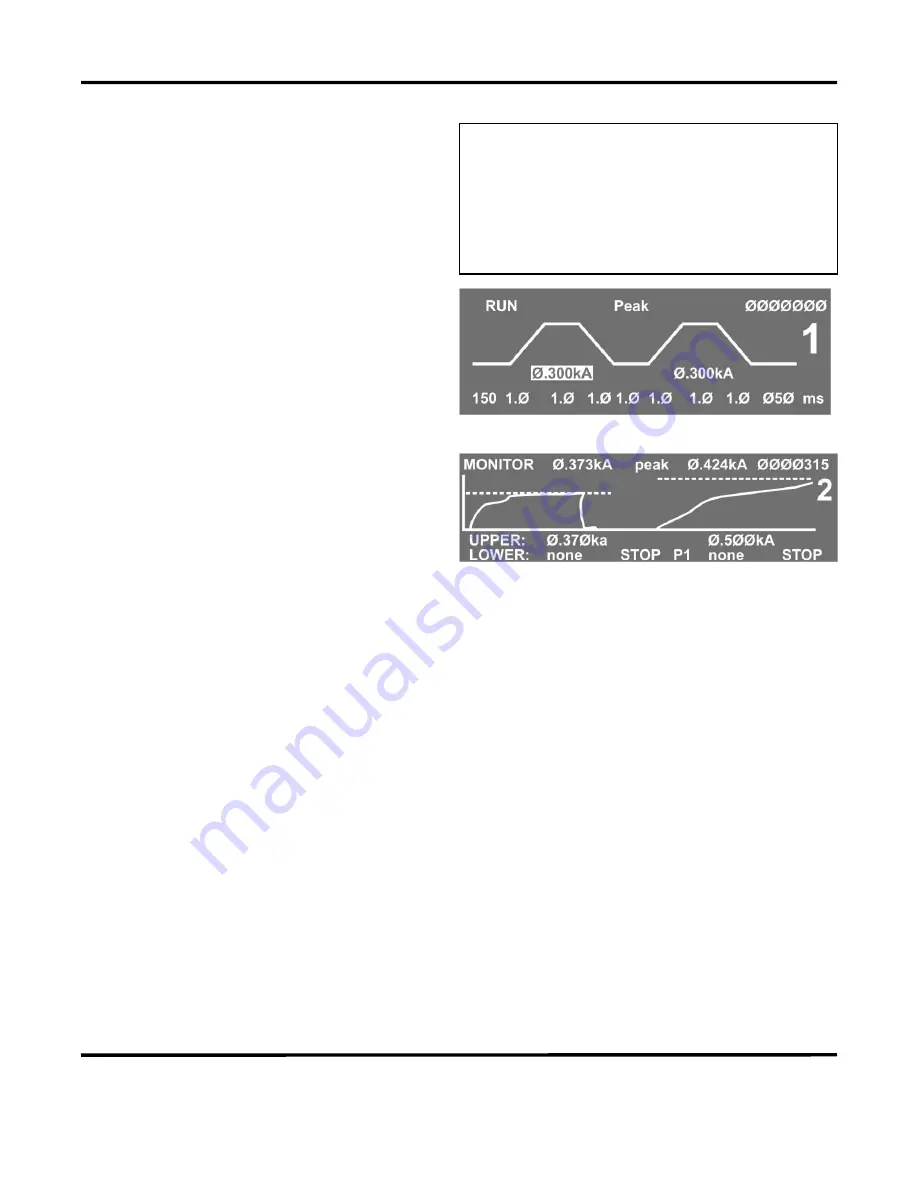

The

RUN

screen allows you to easily modify

any time period, current, voltage, or power

value.

Run Screen

•

The

MONITOR

screen provides instant visual

feedback on the actual current, voltage, or

power used to make each weld. It permits

you to program adjustable limits for both

weld pulses.

Monitor Screen

•

Rear-mounted RS-232 and RS-485 connectors allow for remote programming, weld schedule

selection, and data logging for SPC purposes. The Control has communication and data options

that allows you to connect a single Control, or multiple Controls, to a printer or a computer in

order to:

−

Compile, store, view, and print weld history data for detailed analysis.

−

Remotely program weld schedules on the Control(s).

−

Remotely program menu items on the Control(s).

However, to enable the Control to perform these functions, you must install the software from the

optional

HF25 Advanced Serial Datacom Communications Interface Kit

, commonly referred to as

"the Datacom kit," in a host computer.

Appendix E, Communications

in this manual lists all of the commands that the Control will respond

to, and instructions on how to format commands sent to the Control so it will respond properly.

Summary of Contents for HF25A

Page 9: ...HF25D DC RESISTANCE WELDING SYSTEM 990 333 ix ...

Page 10: ......

Page 20: ......

Page 84: ...CHAPTER 6 CALIBRATION HF25D DC RESISTANCE WELDING SYSTEM 990 333 6 4 Final Calibration Setup ...

Page 113: ......

Page 129: ......

Page 153: ......

Page 171: ......