HF25D LINEAR DC RESISTANCE WELDING CONTROL

990-333

E-1

Appendix E

Communications

Overview

The Control has the ability to communicate with a host computer or with automation control system.

The communications option uses either RS-232 to connect one control to one host or RS-485 multi-drop

architecture to connect up to 30 controls to one host on a single channel. Unitek’s

Weldstat

software will

allow you to connect a single or multiple Controls to a computer in order to:

•

Compile, store, view, and print weld history data for detailed analysis.

•

Check the status of the Control(s).

•

Remotely program weld schedules on the Control(s).

•

Remotely program menu items on the Control(s).

Remote Programming

Most users will find the

Weldstat

software functions sufficient for collecting and using weld history

information and remote schedule programming. However, advanced users may wish to perform

additional programming for custom welding applications. The codes needed to perform remote

programming are listed in

Section II. Communications Protocol and Commands

. Using these codes,

users can write customized software for controlling all functions of the welding control and interfacing

the unit to automation control systems.

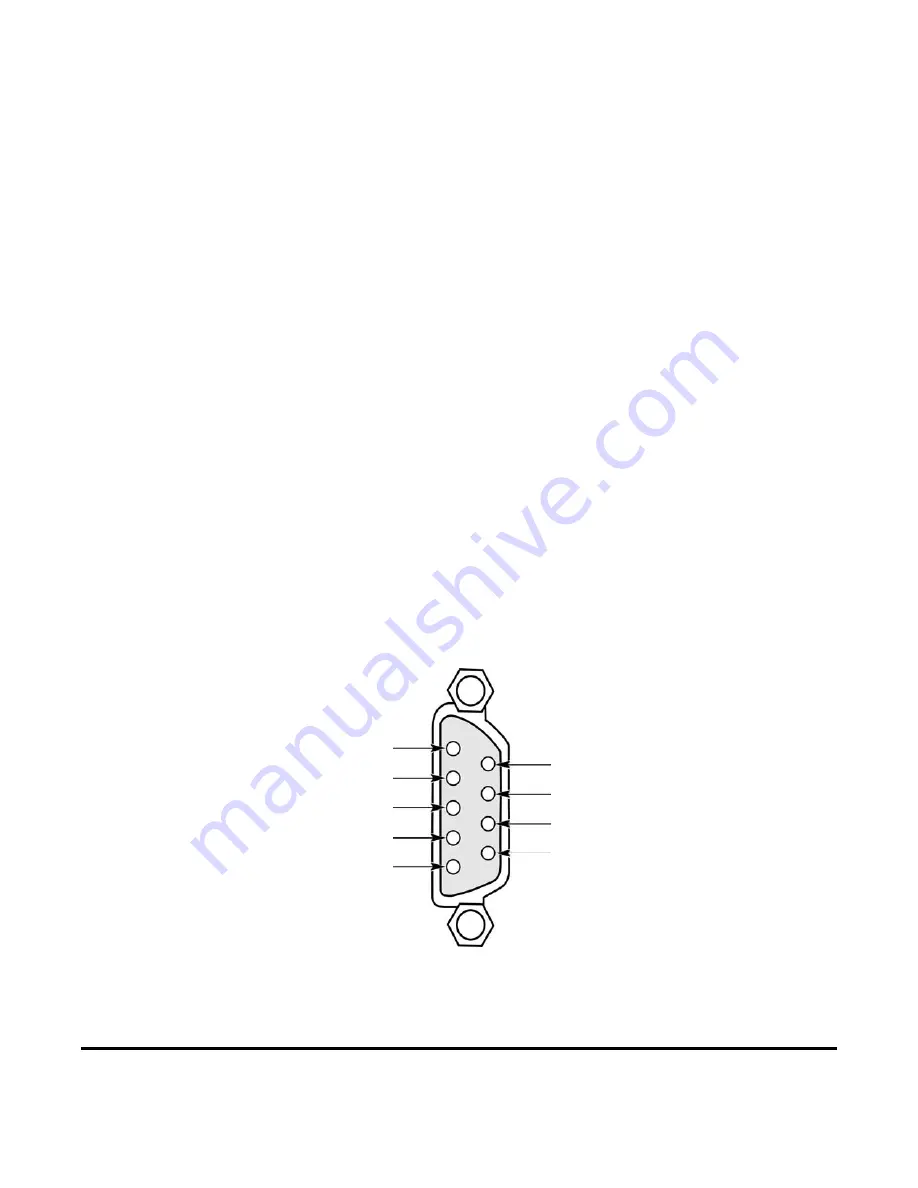

RS-485 Connectors

The unit has two DB-9 (female) connectors wired as follows:

#1 – Not Used

#2 -- Not Used

#3 -- Not Used

#4 -- Tx+

#5 -- Tx-

#6 -- Not Used

#7 -- Not Used

#8 -- Rx+

#9 -- Rx-

Summary of Contents for HF25A

Page 9: ...HF25D DC RESISTANCE WELDING SYSTEM 990 333 ix ...

Page 10: ......

Page 20: ......

Page 84: ...CHAPTER 6 CALIBRATION HF25D DC RESISTANCE WELDING SYSTEM 990 333 6 4 Final Calibration Setup ...

Page 113: ......

Page 129: ......

Page 153: ......

Page 171: ......