CHAPTER 1: DESCRIPTION

HF25D DC RESISTANCE WELDING SYSTEM

1-4

990-333

Section II: Major Components

Major Components

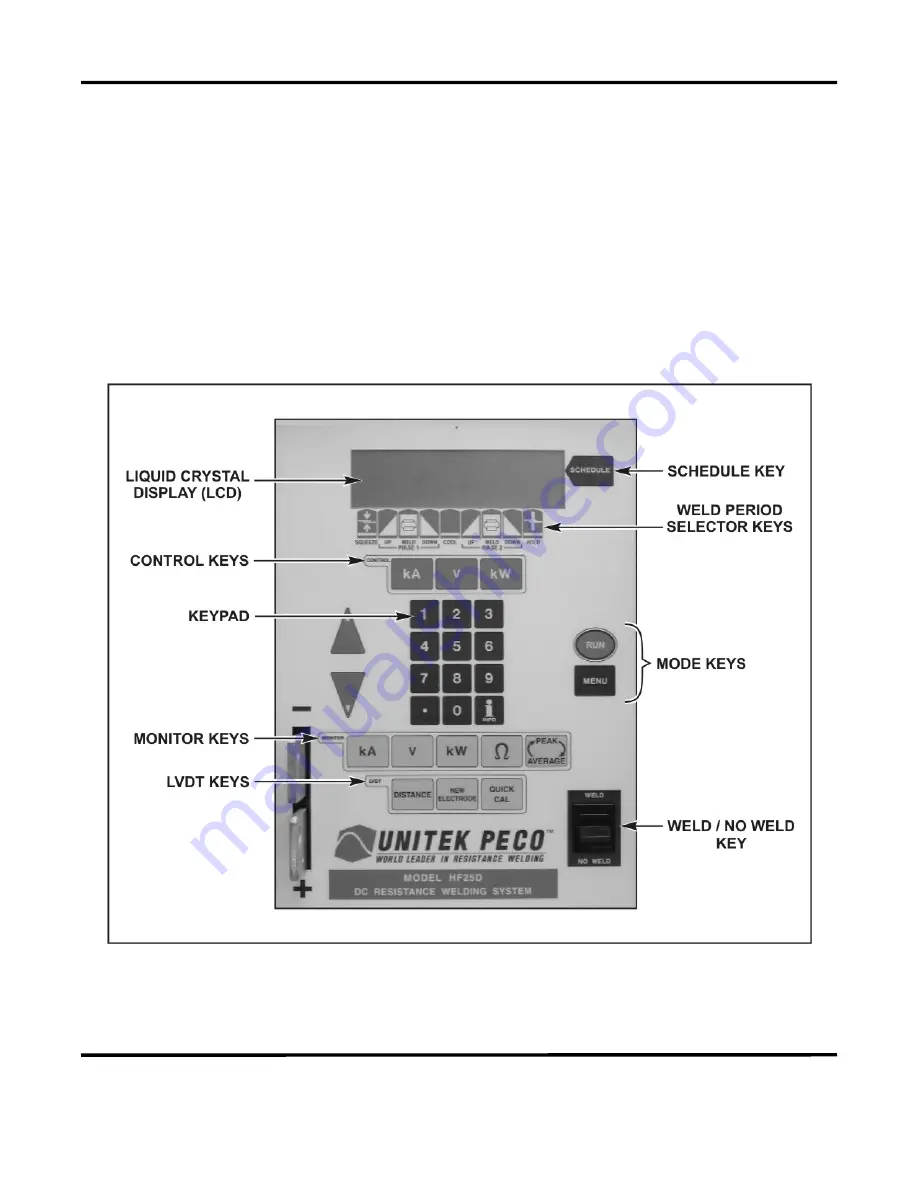

The major components are the front panel, which contains the operator’s controls and indicators, and the

rear panel, which contains fuses, circuit breakers and power and signal connectors. The rear panel

connections are discussed in

Chapter 2

.

Front Panel Display and Display Controls

The front panel of the Control below shows controls and indicators. The function of each item is

described on the following pages.

Front Panel Controls

Summary of Contents for HF25A

Page 9: ...HF25D DC RESISTANCE WELDING SYSTEM 990 333 ix ...

Page 10: ......

Page 20: ......

Page 84: ...CHAPTER 6 CALIBRATION HF25D DC RESISTANCE WELDING SYSTEM 990 333 6 4 Final Calibration Setup ...

Page 113: ......

Page 129: ......

Page 153: ......

Page 171: ......