APPENDIX G: DEFINING THE OPTIMUM PROCESS

HF25D LINEAR DC RESISTANCE WELDING CONTROL

990-333

G-7

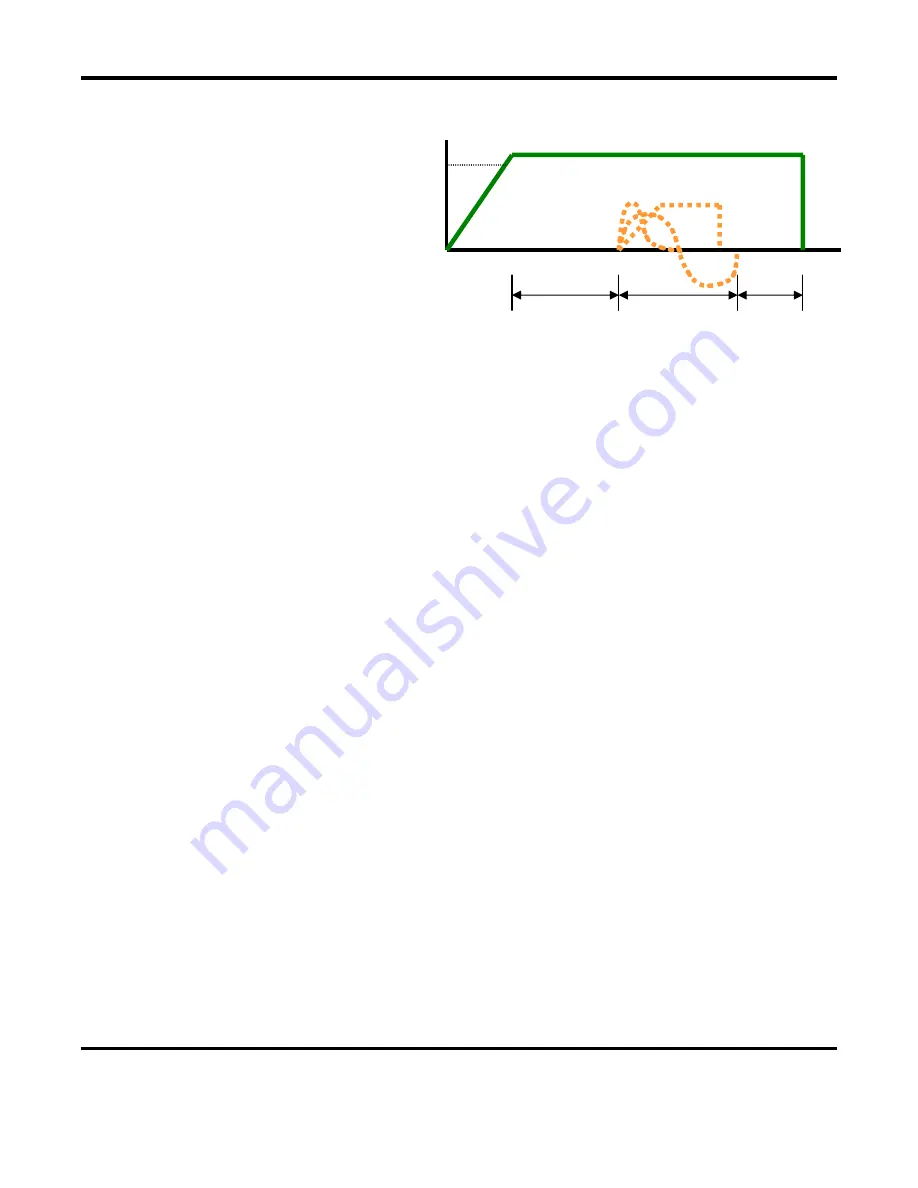

The figure on the right

shows a typical welding

sequence where the force is

applied to the parts; a

squeeze time is then

initiated which allows the

force to stabilize before the

current is fired. Squeeze

time also allows time for

the contact resistances to

reduce as the materials start

to come into closer contact at their interface. A hold time is the initiated after current flows to allow

the parts to cool under pressure before the electrodes are retracted from the parts. Hold time is

important as weld strength develops in this period of time. This basic form of weld profile is

sufficient for the majority of small part resistance welding applications.

Power supply technology selection is based on both the requirements of the application and process. In

general, closed loop power supply technologies are the best choice for their consistent, controlled output

and fast response to changes in resistance during the weld (for further details comparison see Unitek

Equipment "slide rule").

Approach to Weld Development

The first stage in developing a quality welding process is to fix as many of the variables as possible in

the welding equipment set up. The welding variables can be grouped in the following categories:

•

Material variables

−

Base material

−

Plating

−

Size

−

Shape

•

Weld head & mechanical variables

−

Force, squeeze, hold

−

Actuation method

−

Electrode material and shape

•

Power supply variables

−

Energy

−

Time (squeeze, weld, hold)

•

Process variables

−

Tooling, level of automation

−

Repetition rate

−

Part positioning

−

Maintenance, electrode cleaning

•

Quality requirements

−

Pull strength

−

Visual criteria

−

Test method, other weld joint requirements

Squeeze

Heat

Hold

Welding Force

Trigger Force

Current

Summary of Contents for HF25A

Page 9: ...HF25D DC RESISTANCE WELDING SYSTEM 990 333 ix ...

Page 10: ......

Page 20: ......

Page 84: ...CHAPTER 6 CALIBRATION HF25D DC RESISTANCE WELDING SYSTEM 990 333 6 4 Final Calibration Setup ...

Page 113: ......

Page 129: ......

Page 153: ......

Page 171: ......