CHAPTER 3: USING PROGRAMMING FUNCTIONS

HF25 DC RESISTANCE WELDING SYSTEM

990-333

3-15

Section II. Operational States

The Control has seven operational states:

NO

WELD WELD

MENU

MONITOR

TEST ALARM

RUN

You go to the

NO WELD

,

MENU

,

TEST

,

RUN

and

MONITOR

states through the control panel. The

WELD

and

ALARM

states are functions of the force firing switch and foot switch input states.

No Weld State

Setting the

WELD/NO WELD

switch on the control panel to the

NO WELD

position inhibits the delivery of

weld energy if a weld is initiated, and will display a

WELD SWITCH IN NO WELD POSITION

alarm on the

screen. But the Control will still go through its electronic weld cycles as programmed into the selected

weld schedule. Use the no weld state when adjusting the air regulators on air actuated weld heads.

Menu State

Pressing the

MENU

key puts the Control in the

menu state. It brings up menu screens that

enable you to select various options common to

all weld schedules, such as how the Control

interfaces with the force firing switch, foot

switch and weld head.

MAIN MENU

1. SETUP

5. RELAY

2. WELD COUNTER

6 CALIBRATION

3. COPY A SCHEDULE 7. SESET TO DEFAULTS

4. SYSTEM SECURITY 8. RESET TO DEFAULTS

9. CHAIN SCHEDULES

NUMBER Select an item

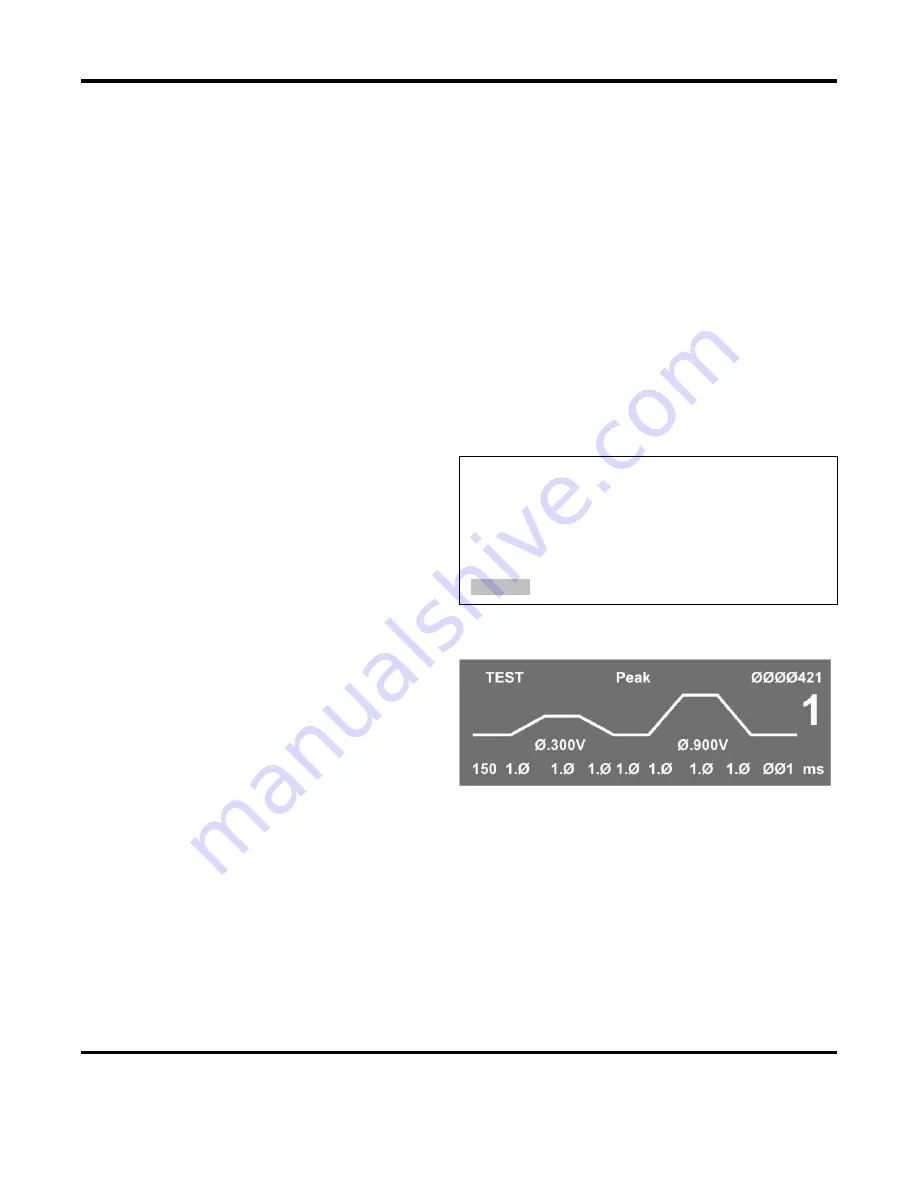

Test State

Pressing the

V

key, or changing the voltage or

time settings while in the voltage feedback

welding mode, puts the Control in the test state.

After making one weld, the Control internally

optimizes the feedback control loop to produce

the fastest rise time, minimum overshoot weld

pulse. The test state is automatically replaced by

the run state for subsequent welds.

Summary of Contents for HF25A

Page 9: ...HF25D DC RESISTANCE WELDING SYSTEM 990 333 ix ...

Page 10: ......

Page 20: ......

Page 84: ...CHAPTER 6 CALIBRATION HF25D DC RESISTANCE WELDING SYSTEM 990 333 6 4 Final Calibration Setup ...

Page 113: ......

Page 129: ......

Page 153: ......

Page 171: ......