CHAPTER 5. MAINTENANCE

HF25D DC RESISTANCE WELDING SYSTEM

5-2

990-333

Section II. Troubleshooting

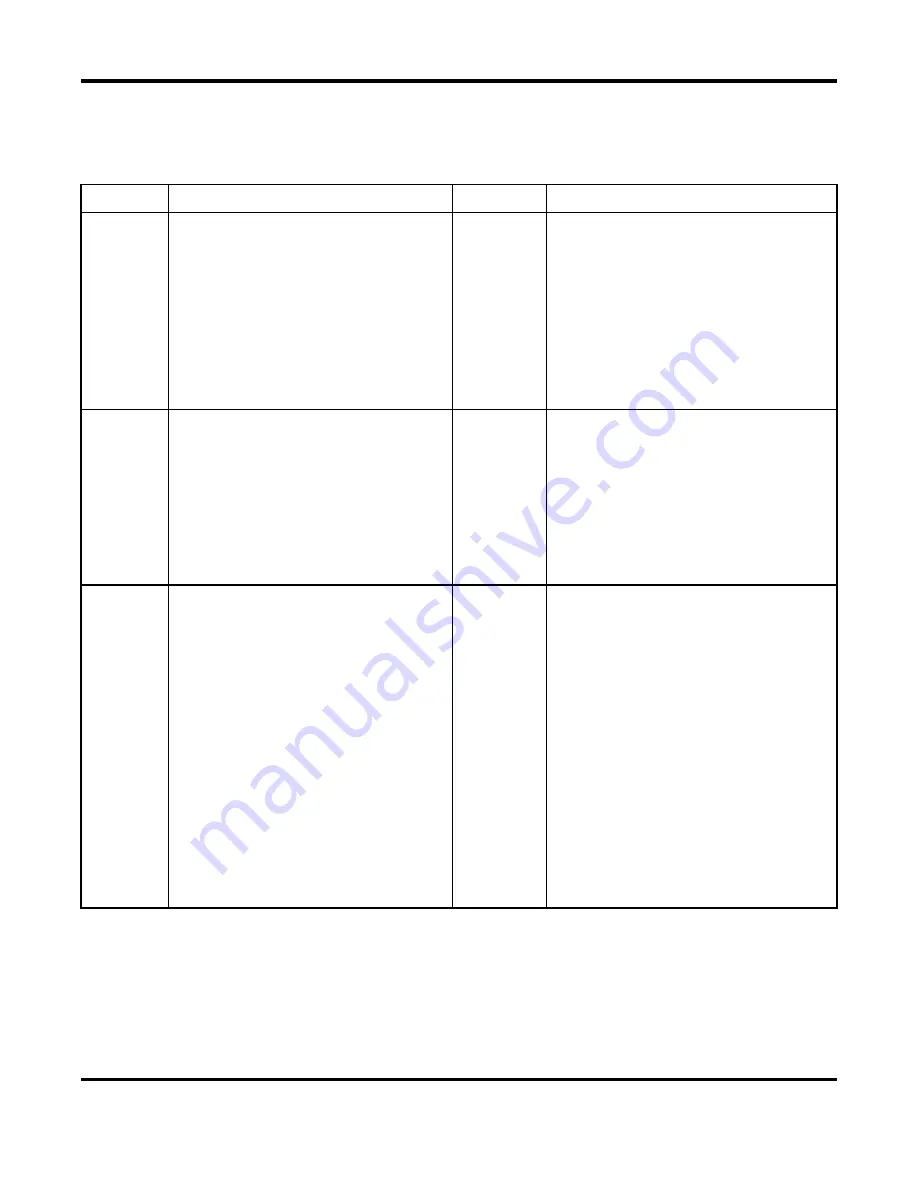

Troubleshooting

Problem

Cause (in order of probability)

Problem

Cause (in order of probability)

Electrode

Damage

1. Excessive current/energy set at HF25

1. Excessive or insufficient weld head

force

1. Wrong electrode tip shape

2. Excessive weld time set at HF25

2. Contaminated weld piece surface/

plating

2. Wrong electrode material

2. Contaminated

electrode surface

Electrode

Sparking

1. Excessive current/energy set at HF25

1. Insufficient weld head force

1. Slow weld head follow-up

1. Incompatible weld piece projection

design

1. Contaminated

weld piece surface/ plating

1. Wrong electrode tip shape

2. Wrong electrode material

2. Contaminated

electrode surface

Electrode

Sticking

1. Contaminated weld piece surface/

plating

1. Wrong electrode material/ tip shape

1. Insufficient weld head force

2. Excessive current/energy set at HF25

2. Excessive weld time set at HF25

2. Contaminated

electrode surface

3. Slow weld head follow-up

Weld Piece

Warping

1. Excessive weld time set at HF25

1. Excessive weld head force

1. Incompatible weld piece projection

design

2. Incompatible weld piece materials

2. Wrong electrode tip shape

3. Excessive current/energy set at HF25

Insufficient

Weld

Nugget

1. Insufficient current/ energy set at HF25

1. Wrong electrode material/ tip shape

1. Worn/mushroomed

electrodes

2. Insufficient weld time set at HF25

2. Incorrect weld head polarity

2. Contaminated weld piece surface/

plating

2. Excessive weld head force

3. Insufficient weld head force

3. Contaminated

electrode surface

3. Incompatible weld piece projection

design

3. Slow weld head follow-up

4. Incompatible weld piece materials

4. No cover gas on weld piece

Metal

Expulsion

1. Excessive current/energy set at HF25

1. Insufficient weld head force

1. Slow weld head follow-up

1. Incompatible weld piece projection

design

2. Contaminated

weld piece surface/ plating

2. Incompatible weld piece materials

2. Contaminated

electrode surface

2. Wrong electrode tip shape

3. No cover gas on weld piece

4. Excessive weld time set at HF25

Summary of Contents for HF25A

Page 9: ...HF25D DC RESISTANCE WELDING SYSTEM 990 333 ix ...

Page 10: ......

Page 20: ......

Page 84: ...CHAPTER 6 CALIBRATION HF25D DC RESISTANCE WELDING SYSTEM 990 333 6 4 Final Calibration Setup ...

Page 113: ......

Page 129: ......

Page 153: ......

Page 171: ......