CHAPTER 6: CALIBRATION

HF25D DC RESISTANCE WELDING SYSTEM

990-333

6-3

7.

The first calibration screen is the

CALIBRATION SHUNT

. This screen asks for the actual

value of the 1000 micro-ohm shunt. The actual value is printed on the exterior of the

R7500-8 shunt. Enter this value using the number keys, and press to continue.

NOTE:

The next calibration screen is the

CURRENT SHUNT

. It is not necessary to change the

current shunt value unless the internal welding transformer was changed. If it was changed,

remove the top cover and enter the shunt value, which is stamped on the copper conductor

connected to the transformer. Press to continue.

8.

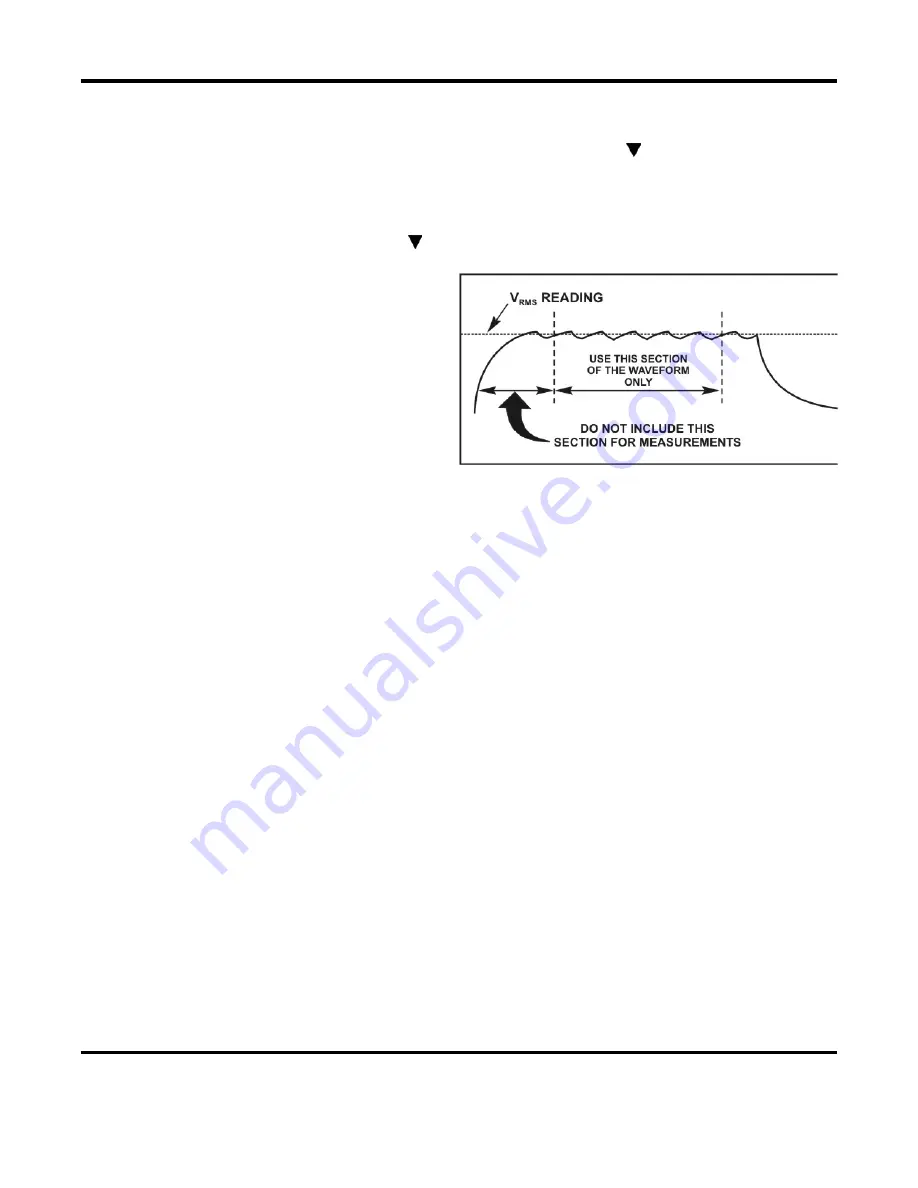

The next two screens are

1. CALIBRATE

D/A HIGH

and

2. CALIBRATE D/A LOW

.

Following the screen instructions, adjust

the energy output using the measuring

parameter feature of the oscilloscope.

NOTE:

Do

not

use a visual

assessment. Press the period [

.

] key to

advance to the next step.

Calibration Signal

9.

The next calibration screen is

CALIBRATE HIGH

. Disconnect the oscilloscope from the shunt

resistor and connect the output of the shunt resistor to the

VOLTAGE SENSE

INPUT

connector using the male BNC to binding post adapter and voltage sense cable. Follow the

screen instructions for this step and the next step,

4. CALIBRATION LOW

.

Summary of Contents for HF25A

Page 9: ...HF25D DC RESISTANCE WELDING SYSTEM 990 333 ix ...

Page 10: ......

Page 20: ......

Page 84: ...CHAPTER 6 CALIBRATION HF25D DC RESISTANCE WELDING SYSTEM 990 333 6 4 Final Calibration Setup ...

Page 113: ......

Page 129: ......

Page 153: ......

Page 171: ......