APPENDIX B: ELECTRICAL AND DATA CONNECTIONS

HF25D DC RESISTANCE WELDING SYSTEM

B-8

990-333

FOOT SWITCH Connector Pin Assignment Summary

Signal Destinations

Pin

No.

Name Type TB

Cntrol

Board

Voltage Max

Current

I/O Comments

1 CGND -- 2-15 J1-15

CGND -- --

Chassis

ground

2

FOOT1

Digital

2-16

J1-16

+24V

10mA

I

Foot switch SW1 (Level 1)

normally open contact

3

FOOT2

Digital

2-17

J1-17

+24V

10mA

I

Foot switch SW2 (Level 2)

normally closed contact

4

FOOTG

Digital

2-18

J1-18

SGND

20mA

I

Foot switch signal ground

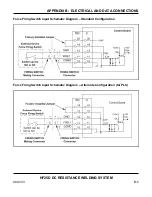

Remote Schedule Selection Inputs

Function

The are two ways to use the remote schedule selection inputs:

•

Schedule Selection Function

•

Schedule Initiation Function

Schedule Selection Function

All weld schedules must be entered and saved to the Control memory locally, through the Control

control panel. Once they are saved, they can be recalled prior to initiating the weld process by placing a

BCD value on the remote schedule selection lines. This may be done with either an external

programmed logic controller (PLC) or host computer.

The

INHIBIT

output signal from the Control can be used to prevent the PLC from beginning a new

welding process. The STOP output signal from the Control can be used to terminate the active weld

process under an emergency condition. Typical PLC timing in relationship to weld head timing is

shown in the PLC Timing Diagram on the next page.

Summary of Contents for HF25A

Page 9: ...HF25D DC RESISTANCE WELDING SYSTEM 990 333 ix ...

Page 10: ......

Page 20: ......

Page 84: ...CHAPTER 6 CALIBRATION HF25D DC RESISTANCE WELDING SYSTEM 990 333 6 4 Final Calibration Setup ...

Page 113: ......

Page 129: ......

Page 153: ......

Page 171: ......