UNITED FIRE SYSTEMS

STANDPIPE-

PAC™ MODEL SSS-101

DESIGN, INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

REVISION 2.00

P/N 10-540101-001

Page 11

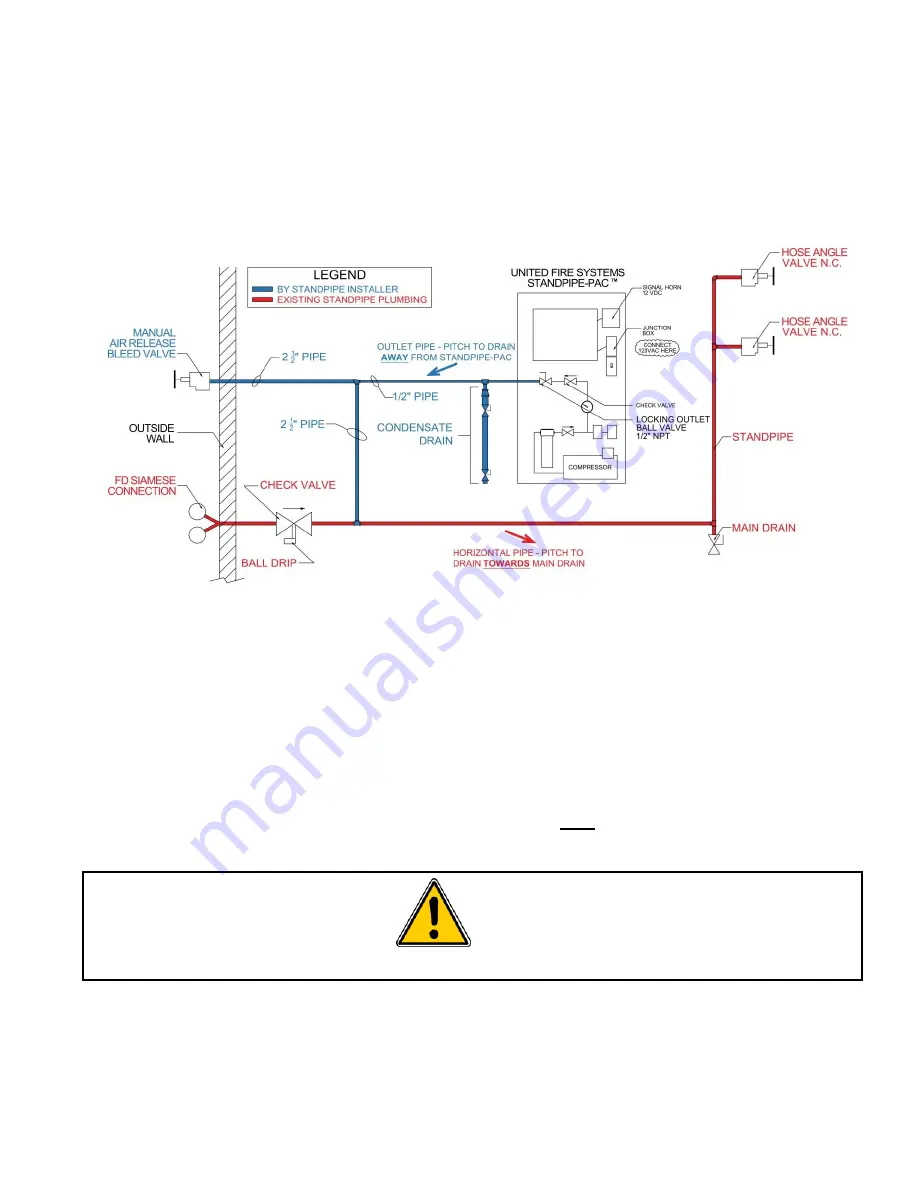

3.3.2.

Piping.

See Figure 9.

The piping in

BLUE

is to be installed by the

STANDPIPE-

PAC™

system installer. Use

Sch. 40 black pipe and Class 150 fittings. The tee to connect the

STANDPIPE-

PAC™

shall be located after the

check valve, and should be located before the drain valve. Connect 1/2” pipe to point labeled OUTLET on

STANDPIPE-

PAC™

unit. Ensure that the standpipe is NOT PRESSURIZED prior to cutting in the tee at the

installation location.

All dry standpipes should always be maintained as dry as possible. This is to minimize internal corrosion year round,

as well as to minimize ice accumulation and blockage during cold weather.

To facilitate drainage, the low point of the standpipe must have a main drain valve, and all pipe should be pitched

towards that main drain valve. The main drain valve should be opened on a regular basis, permitting any water

accumulation or pooled water from testing to drain.

Dry standpipes installed with supervisory systems shall be installed per Figure 9 above. The diagram indicates several

important facts:

1. Where possible, the

STANDPIPE-

PAC™

should NOT be the low point of the dry standpipe system.

2. The piping from the

STANDPIPE-

PAC™

should be pitched away from the

STANDPIPE-

PAC™

so that

accumulated water drains away from the

STANDPIPE-

PAC™

outlet.

3. Install the Auxiliary Condensate Drain Device where shown on Figure 10, per 3.3.4.

3.3.3.

Manual Air Release Bleed Valve.

See Figure 2.

Locate the manual air release bleed valve on the exterior of

the building in proximity to the fire department siamese connection feeding the standpipe protected by the

STANDPIPE-

PAC™.

Attach the cap and chain to the valve. Secure the provided nameplate to the building or the

valve so that the fire department can clearly identify the purpose of the valve and follow the instructions on the

nameplate.

Figure 9

–

STANDPIPE-

PAC™

Installation

CAUTION

Failure to confirm that the standpipe is NOT pressurized could result in personal injury and / or property damage.