Page 27

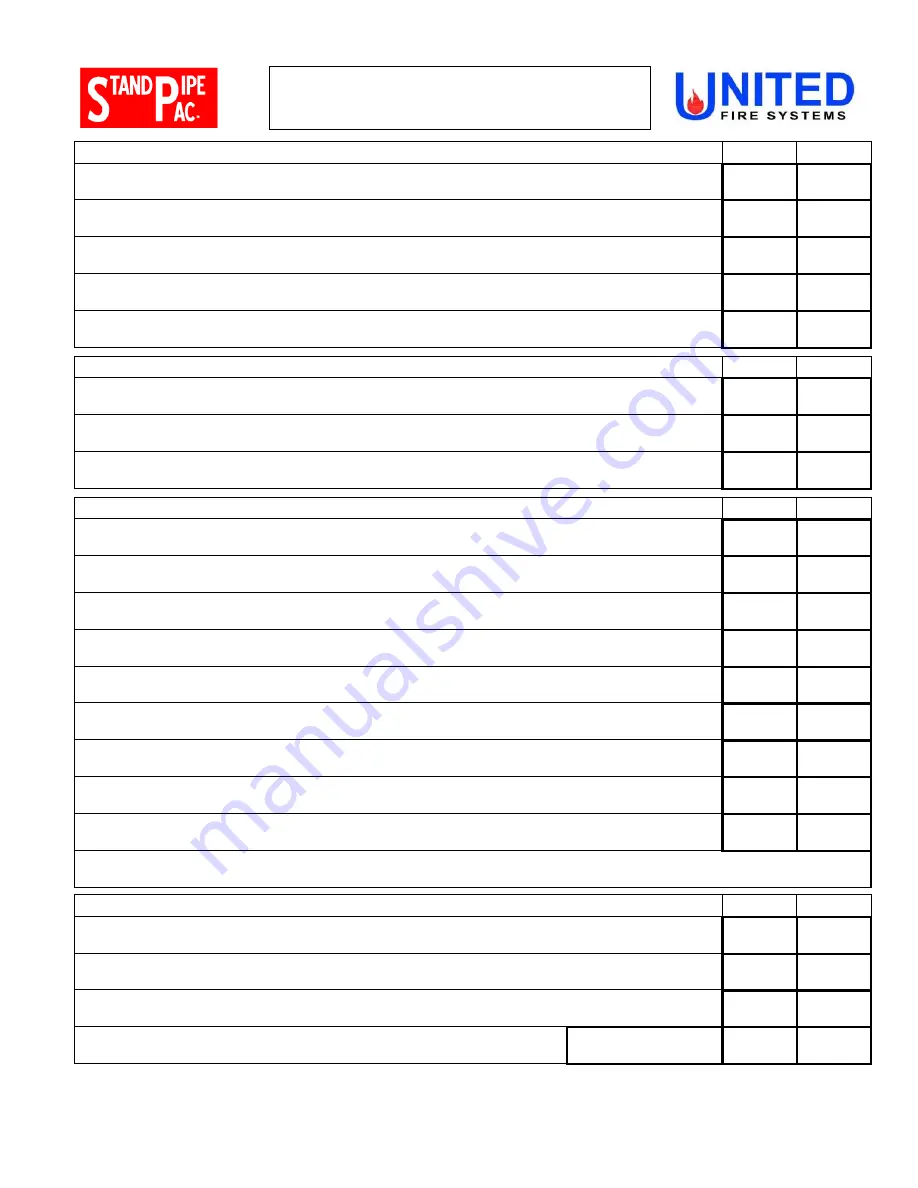

LOW PRESSURE SWITCH TEST

YES

NO

Is the compressor disconnect switch OFF, and has the unit outlet lockable shutoff valve been moved to

CLOSED?

Has the button on the test / service device been operated, and is the pressure gauge needle moving

DOWN?

When the pressure gauge needle reaches approximately 7 PSIG, does the control unit ALARM indicator

come ON, and do the signals operate?

Has the button on the test / service device been released?

Has the SILENCE switch been pressed once to acknowledge the alarm, and then pressed again for 2

seconds, turning the signals OFF?

COMPRESSOR CONTROL SWITCH TEST

YES

NO

Has the compressor disconnect switch been moved to ON?

Has the compressor started, and is the pressure gauge needle moving UP?

When the pressure gauge needle reaches approximately 18 PSIG, does the compressor automatically

shut off?

HIGH PRESSURE SWITCH TEST

YES

NO

Is the compressor disconnect switch ON, and is the unit lockable shutoff valve CLOSED?

Is the control unit clear, with only the AC POWER indicator ON?

Has the button on the test / service device been operated, and is the pressure gauge needle moving UP?

When the pressure gauge needle reaches approximately 23 PSIG, does the control unit ALARM indicator

come ON, and do the signals operate?

Has the button on the test / service device been released?

Has the SILENCE switch been pressed once to acknowledge the alarm, and then pressed again for 2

seconds, turning the signals OFF?

Has the compressor disconnect switch been moved to OFF?

Has the button on the test / service device been operated, and held until pressure gauge needle is

between 13 and 18 PSIG?

Has the compressor disconnect switch been moved to ON, and the unit lockable shutoff valve been

moved to OPEN?

NOTE: Compressor may start. When pressure gauge needle stabilizes between 13 and 18 PSIG, compressor

should be OFF.

STANDPIPE DEPRESSURIZATION TEST

YES

NO

Has a cap been removed from a manual air release bleed valve, and the valve moved to all the way

OPEN?

Does the pressure gauge reading drop to near zero in 3 minutes or less?

Has the manual air release bleed valve been CLOSED, and the cap replaced?

Has the time for the standpipe to refill to minimum 13 PSIG been recorded?

MINUTES

COMMISSIONING WORKSHEET AND CHECKLIST

STANDPIPE-PAC

™ SUPERVISORY SYSTEM

UFS-238B REVISION 1.00

– PAGE 2 OF 3