-19-

© 2021 United States Stove Company

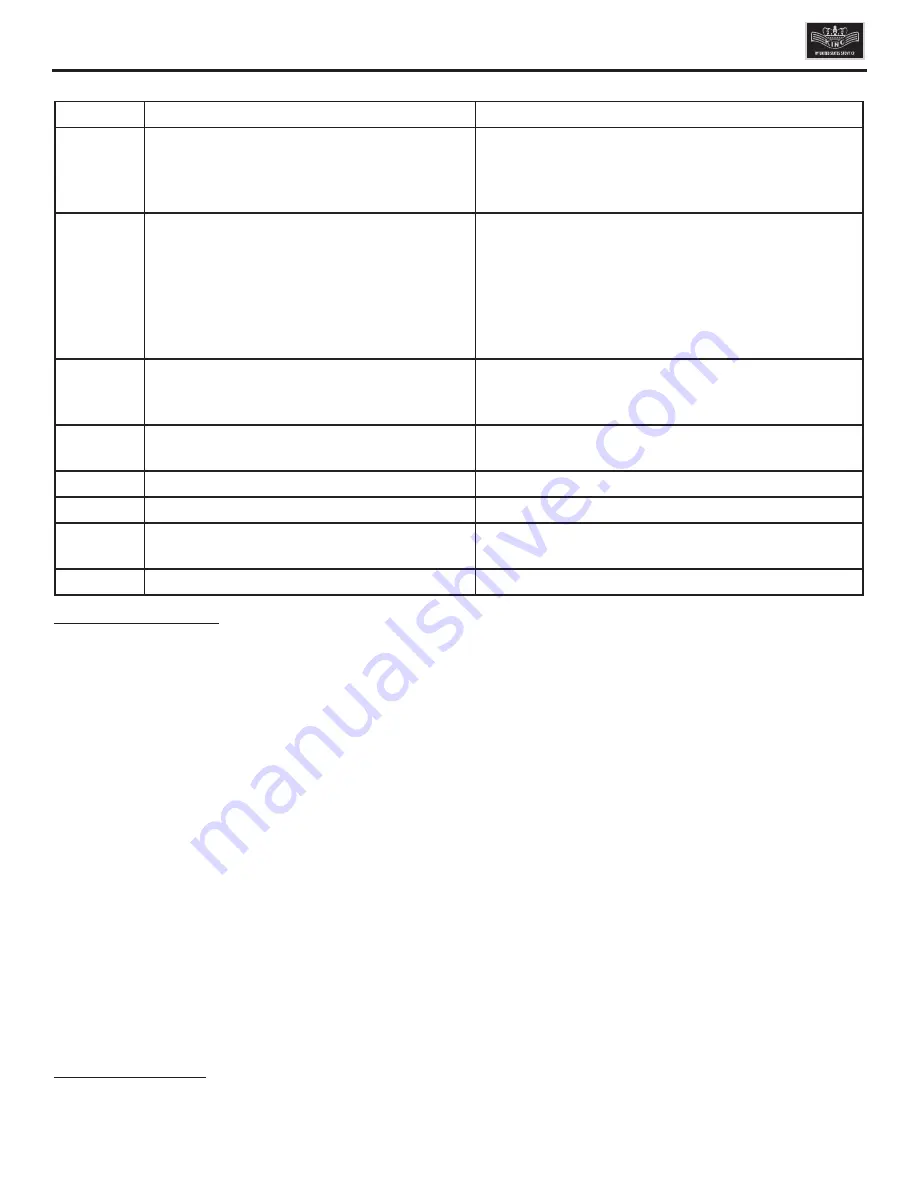

Error Code

Error Description

Possible Causes

Err1

The high limit temperature sensor has tripped.

Inadequate ventilation.

Room fan failure.

Exhaust Blockage.

Electrical Open in wiring.

Err2

Stove ran out of fuel during normal operation.

Hopper Empty.

Auger output failure or jam.

Flame of fuel quality caused fire to burn too slowly or

go out.

Electrical Open in wiring.

The high limit thermosdisc has tripped and will need to

be manually reset.

Err3

The stove was unable to reach the Room Fan

On temperature within the start-up time.

Flame or Fuel quality caused the fire to burn too slowly

or go out.

Auger output failure or jam Hopper empty on start-up.

Err4

The power failed while the stove was hot, and

when power was restored, the fire was out.

Electrical Open in wiring.

Power loss

Err5

The Auger output fuse has blown.

Auger motor jammed or bad.

Err6

The Ignitor output fuse has blown.

Ignitor shorted out or bad.

Err7

The Draft Fan (Exhaust Fan) output fuse has

blown.

Draft Fan motor jammed or bad.

Err8

The Room Fan output fuse has blown.

Room fan motor jammed or bad.

DISPLAY INDICATORS

Several situations or events are indicated in normal operation by blinking display indicators or segments in the display:

Flashing On Indicator -

This means that the stove is in the “Start Up” state waiting for the ignition procedure to

complete.

Flashing Off Indicator -

This indicates that the stove is in the “Shut Down” state waiting for the off button, or for a 15

minute period after the stove was turned off, or for the stove to cool down, or for the door to be closed.

Flashing dash in Heat Range Display -

This indicates that the stove is in the normal run mode and is ramping from the

current heat range setting to the target heat range setting. Once the ramp is complete, the dash will stop flashing. For

ramping from heat range 1 to 5, the default time is 12 minutes (with a 90 second ramp time).

Flashing Automatic Mode Indicator -

This indicates that the stove is in normal operation and is running in the

automatic mode. However, either the draft fan or room fan setting is manually configured.

Flashing Draft Fan Setting Indicator -

This indicates that the stove is in normal operation and that the vacuum sensor

detects a loss of pressure either because the door is open or because there is a negative pressure in the room with

respect to the exhaust.

Flashing Aux Indicator -

This indicates that the ignitor is on during the lighting stage.

Quickly (changes twice per second) Flashing Heat Range Setting Indicator -

This indicates that the stove is in

normal operation and that an over-temperature condition exists causing the fuel to stop.

Slowly (changes once per second) Flashing Heat Range Setting Indicator -

This indicates that the stove is in a cut

back condition in an attempt to prevent an over-temperature shut down.

FACTORY DEFAULTS

To return the control to its original factory default settings, press and hold the AUX UP and AUX DOWN buttons

together for three seconds.

TROUBLESHOOTING GUIDE