© 2022 United States Stove Company

7

Use no more than 180 degrees of elbows (two 90-degree

elbows, or two 45-degree and one 90-degree elbow, etc.)

to maintain adequate draft.

IMPORTANCE OF PROPER DRAFT

Draft is the force which moves air from the appliance up

through the chimney. The amount of draft in your chimney

depends on the length of the chimney, local geography,

nearby obstructions and other factors. Too much draft

may cause excessive temperatures in the appliance.

Inadequate draft may cause backpuffing into the room and

‘plugging’ of the chimney. Inadequate draft will cause the

appliance to leak smoke into the room through appliance

and chimney connector joints. An uncontrollable burn or

excessive temperature indicates excessive draft. Take into

account the chimney’s location to ensure it is not too close

to neighbours or in a valley which may cause unhealthy or

nuisance conditions.

PELLET VENT TYPE

A certified 3-inch or 4-inch type “PL” pellet vent exhaust

system must be used for installation and attached to the

pipe connector provided on the back of the stove (use a

3-inch to 4-inch adapter for 4-inch pipe). The connection

at the back of the stove must be sealed using Hi-Temp

RTV. Use a 4-inch vent if the vent height is over 12-feet or

if the installation is over 2,500 feet above sea level. We

recommend the use of Simpson Dura-Vent® or Metal-

Fab® pipe (if you use other pipes, consult your local

building codes and/or building inspectors). Do not use

Type-B Gas Vent pipe or galvanized pipe with this unit. The

pellet vent pipe is designed to disassemble for cleaning

and should be checked several times during the burning

season. The pellet vent pipe is not furnished with the unit

and must be purchased separately.

PELLET VENT INSTALLATION

The installation must include a clean-out tee to enable

collection of fly ash and to permit periodic cleaning of the

exhaust system. 90-degree elbows accumulate fly ash

and soot thereby reducing exhaust flow and performance

of the stove. Each elbow or tee reduces draft potential by

30% to 50%. All joints in the vent system must be fastened

by at least 3 screws, and all joints must be sealed with Hi-

Temp RTV silicone sealant to be airtight. The area where

the vent pipe penetrates to the exterior of the home must

be sealed with silicone or other means to maintain the

vapor barrier between the exterior and the interior of the

home. Vent surfaces can get hot enough to cause burns if

touched by children. Noncombustible shielding or guards

may be required.

PELLET VENT TERMINATION

Do not terminate the vent in an enclosed or semi-enclosed

area, such as; carport, garage, attic, crawl space, under a

sun deck or porch, narrow walkway, or any other location

that can build up a concentration of fumes. Termination in

one of these areas can also lead to unpredictable pressure

situations with the appliance, and could result in improper

performance and/or malfunction. The termination

must exhaust above the outside air inlet elevation. The

termination must not be located where it will become

plugged by snow or other materials. Do not terminate the

venting into an existing steel or masonry chimney.

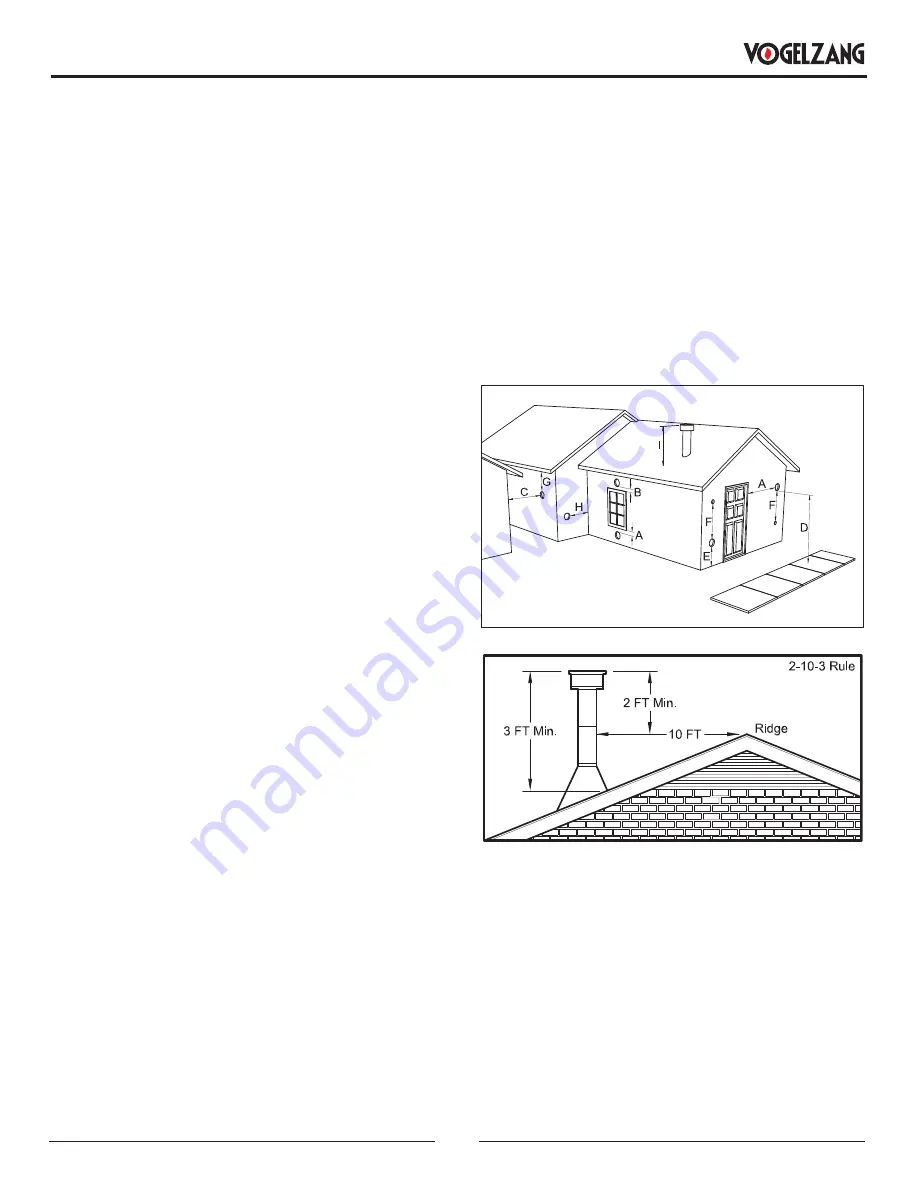

VENT TERMINATION CLEARANCES

A. Minimum 4-foot (1.22m) clearance below or beside

any door or window that opens.

B. Minimum 1-foot (0.3m) clearance above any door or

window that opens.

C. Minimum 3-foot (0.91m) clearance from any adjacent

building.

D. Minimum 7-foot (2.13m) clearance from any grade

when adjacent to public walkways.

E. Minimum 2-foot (0.61m) clearance above any grass,

plants, or other combustible materials.

F. Minimum 3-foot (0.91m) clearance from an forced air

INSTALLATION

Summary of Contents for KP5522

Page 11: ...Project 22 753 Model KP5522 Page 10 Appliance Front Appliance Left...

Page 12: ...Project 22 753 Model KP5522 Page 11 Appliance Right Appliance Rear...

Page 14: ...Project 22 753 Model KP5522 Page 13 Pellet Fuel Analysis...

Page 17: ...Project 22 753 Model KP5522 Page 16 Sealed Unit...

Page 54: ......

Page 55: ......

Page 56: ......

Page 58: ...Project 22 751 Model Charnwood Skye E700 Page 16 Tunnel Schematic...

Page 102: ......

Page 103: ......

Page 104: ......

Page 129: ...2022 United States Stove Company 25 NOTES...

Page 177: ...2022 United States Stove Company 25 NOTES...

Page 272: ...24 2022 United States Stove Company NOTES...

Page 308: ......

Page 309: ......

Page 311: ......

Page 312: ......

Page 318: ......

Page 319: ......