-13-

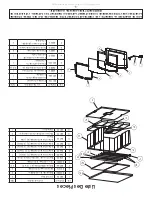

31 to 32 lbs

26 to 27 lbs

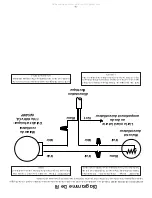

CONTROL

LEVER

A

(Primary Air)

CONTROL

LEVER

B

(High Burn)

OPEN

CLOSED

OPEN

CLOSED

HEARTH

CONTROL

LEVER

A

(Primary Air)

CONTROL

LEVER

B

(High Burn)

OPEN

CLOSED

OPEN

CLOSED

HEARTH

CONTROL

LEVER

A

(Primary Air)

CONTROL

LEVER

B

(High Burn)

OPEN

CLOSED

OPEN

CLOSED

HEARTH

CONTROL

LEVER

A

(Primary Air)

CONTROL

LEVER

B

(High Burn)

OPEN

CLOSED

OPEN

CLOSED

HEARTH

CONTROL

LEVER

A

(Primary Air)

CONTROL

LEVER

B

(High Burn)

OPEN

CLOSED

OPEN

CLOSED

HEARTH

CONTROL

LEVER

A

(Primary Air)

CONTROL

LEVER

B

(High Burn)

OPEN

CLOSED

OPEN

CLOSED

HEARTH

CONTROL

LEVER

A

(Primary Air)

CONTROL

LEVER

B

(High Burn)

OPEN

CLOSED

OPEN

CLOSED

HEARTH

CONTROL

LEVER

A

(Primary Air)

CONTROL

LEVER

B

(High Burn)

OPEN

CLOSED

OPEN

CLOSED

HEARTH

CONTROL

LEVER

A

(Primary Air)

CONTROL

LEVER

B

(High Burn)

OPEN

CLOSED

OPEN

CLOSED

HEARTH

CONTROL

LEVER

A

(Primary Air)

CONTROL

LEVER

B

(High Burn)

OPEN

CLOSED

OPEN

CLOSED

HEARTH

CONTROL

LEVER

A

(Primary Air)

CONTROL

LEVER

B

(High Burn)

OPEN

CLOSED

OPEN

CLOSED

HEARTH

CONTROL

LEVER

A

(Primary Air)

CONTROL

LEVER

B

(High Burn)

OPEN

CLOSED

OPEN

CLOSED

HEARTH

CONTROL

LEVER

A

(Primary Air)

CONTROL

LEVER

B

(High Burn)

OPEN

CLOSED

OPEN

CLOSED

HEARTH

CONTROL

LEVER

A

(Primary Air)

CONTROL

LEVER

B

(High Burn)

OPEN

CLOSED

OPEN

CLOSED

HEARTH

CONTROL

LEVER

A

(Primary Air)

CONTROL

LEVER

B

(High Burn)

OPEN

CLOSED

OPEN

CLOSED

HEARTH

CONTROL

LEVER

A

(Primary Air)

CONTROL

LEVER

B

(High Burn)

OPEN

CLOSED

OPEN

CLOSED

HEARTH

Push both air control slides to the fully open position. Light the newspaper and close the door. Once the kindling

has burned down to a starter coal bed, load the unit with approximately 26 to 27 lbs of fuel for the first high burn

load.

After the first high burn load and the stove is well warmed up, adjust the unit as needed for a medium or low

burn setting.

For a medium burn, once the high burn fuel load is burned down to an established coal bed, load the unit with

31 to 32 lbs of cordwood and keep the door slightly open for 2 minutes. After two minutes close the door. Keep

the secondary airslide fully open for 10 minutes then close completely and set the primary airslide halfway closed.

At the 15 minute point of loading your fuel, the primary air slide should be set at the medium setting which is

about 1/2 inch open from the fully closed position.

For a low burn setting once the high burn (or medium) fuel load is burned down to an established coal bed, load

the unit with 31 to 32 lbs of cordwood and leave the door open for two minutes. After two minutes close the door.

Keep the secondary airslide fully open for 10 minutes then close completely and set the primary airslide halfway

closed. At the 15 minute point of loading your fuel, the primary air slide should be set at the low setting which is

pulling the airslide completely out toward you. NOTE: Do not close the air too quickly. Closing the air too quickly

will cause the unit to smoke.

ADDING FUEL

1.

Once you have obtained a good bed of embers, you should reload the unit. To do so, open the air controls

to maximum a few seconds before opening the stove’s door.

2.

Open the door very slowly; open it one or two inches for 5 to 10 seconds, before opening it completely to

increase the draft and thus eliminate the smoke which is stagnant in a state of slow combustion in the stove.

3.

Rake the glowing embers to the front of the stove. Add fuel being careful not to overload or overfire the

appliance. When adding fuel be careful not to smother the fire. Do not build fires against glass and make sure

the embers do not obstruct the air inlet. Do not allow logs to roll and strike the glass.

NOTE: For optimal operation of this unit, it is recommend to operate it with a wood load approximately equivalent

to the height of fire bricks. It is important to note that wood combustion consumes ambient oxygen in the room. In

the case of negative pressure, it is a good idea to allow fresh air in the room, either by opening a window slightly

or by installing a fresh air intake system on an outside wall.

WARNINGS:

•

NEVER OVERFIRE YOUR STOVE. IF ANY PART OF THE STOVE STARTS TO GLOW RED, OVER FIRING IS HAPPENING.

READJUST THE AIR INTAKE CONTROL AT A LOWER SETTING.

•

THE INSTALLATION OF A LOG CRADLE OR GRATES IS NOT RECOMMENDED IN YOUR WOOD STOVE. BUILD FIRE

DIRECTLY ON FIREBRICK.

•

NEVER PUT WOOD ABOVE THE FIREBRICK LINING OF THE FIREBOX.

•

ATTEMPTS TO ACHIEVE HEAT OUTPUT RATES THAT EXCEED HEATER DESIGN SPECIFICATIONS CAN RESULT IN

PERMANENT DAMAGE TO THE HEATER.

All manuals and user guides at all-guides.com