12

Chimney Installation

IMPORTANCE OF PROPER DRAFT

Draft is the force which moves air from the appliance up through the chimney. The amount of draft in your

chimney depends on the length of the chimney, local geography, nearby obstructions and other factors. Too

much draft may cause excessive temperatures in the appliance. Inadequate draft may cause back puffing into

the room and ‘plugging’ of the chimney. Inadequate draft will cause the appliance to leak smoke into the room

through appliance and chimney connector joints.

An uncontrollable burn or excessive temperature indicates excessive draft.

Take into account the chimney’s location to insure it is not too close to neighbors or in a valley which may cause

unhealthy or nuisance conditions.

CHIMNEY

Your wood furnace may be hooked up with a factory built or masonry chimney, matching the diameter of the

exhaust. If you are using a factory built chimney, it must comply with UL 103 or CSA-B365 standard; therefore it must

be a Type HT (2100°F). It is extremely important that it be installed according to the manufacturer’s specifications.

If you are using a masonry chimney, it is important that it be built in compliance with the specifications of the

National Building Code. It must be lined with fire clay bricks, metal or clay tiles sealed together with fire cement.

(Round flues are the most efficient).

The interior diameter of the chimney flue must be 6”. A flue which is too small may cause draft problems, while a

large flue favors rapid cooling of the gas, and hence the build-up of creosote and the risk of chimney fires. Note

that it is the chimney and not the furnace which creates the draft effect; your furnace’s performance is directly

dependent on an adequate draft from your chimney.

Do not connect this unit to a chimney flue serving another appliance.

The following recommendations may be useful for the installation of your chimney:

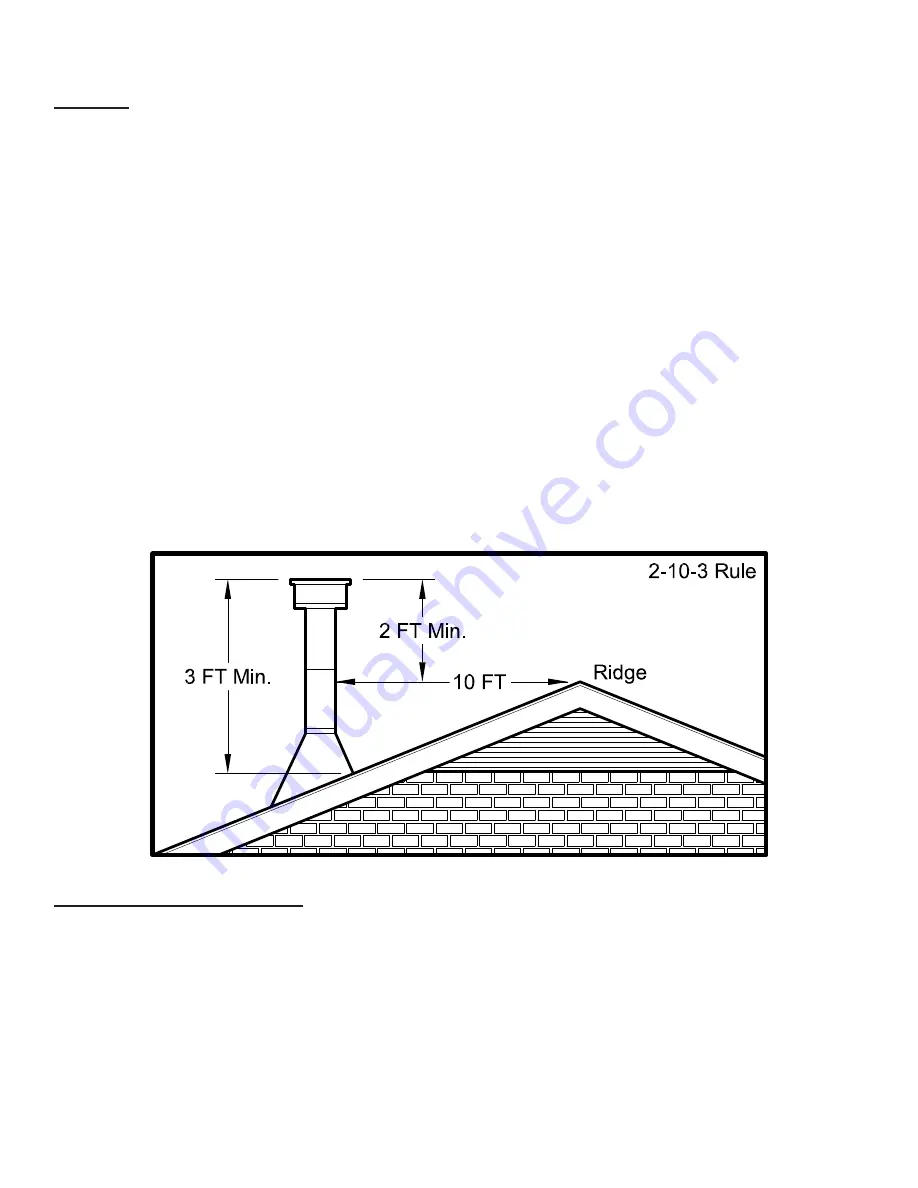

• It must rise above the roof at least 3’ (0.9m) from the uppermost point of contact.

• The exterior portion should be double or triple wall pipe to ensure proper draft.

• The chimney must exceed any part of the building or other obstruction within a 10’ (3.04m) distance by a

height of 2’ (0.6m).

• Installation of an interior chimney is always preferable to an exterior chimney. The interior chimney will be

hotter than an exterior chimney that is being cooled by the ambient air outside the house. Therefore the gas

which circulates will cool slower, thus reducing the build-up of creosote and the risk of chimney fires.

• The draft caused by the tendency for hot air to rise will be increased with an interior chimney.

• Using a fire screen at the extremity of the chimney requires regular inspection in order to insure that it is not

obstructed thus blocking the draft, and it should be cleaned when used regularly.

Summary of Contents for Clayton CL1660E

Page 9: ...9 INSTALLATION ADD ON INSTALLATION...

Page 27: ...27...