10

OPERATING INSTRUCTIONS

CAUTIONS: HOUSE FIRE HAZARDS

•

DO NOT STORE WOOD ON FLOOR PROTECTOR,

UNDERNEATH STOVEPIPE(S) IF APPLICABLE,

OR ANYWHERE WITHIN CLEARANCES TO

COMBUSTIBLE SURFACES SPECIFIED FOR THIS

APPLIANCE.

•

NEVER OPERATE WITH SECONDARY TUBES,

FIBER BOARD, OR INSULATION REMOVED.

OPERATING SAFETY PRECAUTIONS

•

NEVER OVERFIRE THIS APPLIANCE BY BUILDING

EXCESSIVELY HOT FIRES AS A HOUSE/BUILDING

FIRE MAY RESULT. YOU ARE OVERFIRING THE

APPLIANCE IF IT BEGINS TO GLOW OR TURN

RED.

• NEVER BUILD EXCESSIVELY LARGE FIRES IN

THIS TYPE OF APPLIANCE AS DAMAGE TO THE

FIREBOX OR SMOKE LEAKAGE MAY RESULT.

• DO NOT BUILD FIRE TOO CLOSE TO GLASS.

• HOT WHILE IN OPERATION. KEEP CHILDREN,

CLOTHING, AND FURNITURE AWAY. CONTACT

MAY CAUSE SKINS BURNS. DO NOT TOUCH THE

APPLIANCE UNTIL IT HAS COOLED.

• PROVIDE ADEQUATE AIR FOR COMBUSTION

TO THE ROOM WHERE THE APPLIANCE IS

INSTALLED.

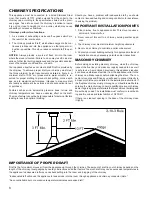

• INSPECT CHIMNEY LINER EVERY 60 DAYS.

REPLACE LINER IMMEDIATELY IF IT IS RUSTING

OR LEAKING SMOKE INTO THE ROOM.

•

ATTEMPTS TO ACHIEVE HEAT OUTPUT

RATES THAT EXCEED HEATER DESIGN

SPECIFICATIONS CAN RESULT IN PERMANENT

DAMAGE TO THE HEATER.

WARNING: EXPLOSION HAZARD

•

NEVER USE CHEMICALS, GASOLINE, GASOLINE-

TYPE LANTERN FUEL, KEROSENE, CHARCOAL

LIGHTER FLUID, OR SIMILAR FLAMMABLE

LIQUIDS TO START OR “FRESHEN UP” A FIRE IN

THE APPLIANCE.

• KEEP ALL FLAMMABLE LIQUIDS, ESPECIALLY

GASOLINE, OUT OF THE VICINITY OF THE

APPLIANCE - WHETHER IN USE OR IN STORAGE.

NOTICE: USE SOLID WOOD FUEL ONLY! DO

NOT BURN GARBAGE , OR FLAMMABLE

FLUIDS. DO NOT USE COAL. THIS APPLIANCE

IS NOT DESIGNED TO ACCOMMODATE THE

AIR FLOW (DRAFT) REQUIRED TO PROPERLY

BURN COAL OR COAL PRODUCTS. DO NOT

ELEVATE THE FIRE USING GRATES OR IRONS.

BUILD THE FIRE DIRECTLY ON THE FIREBRICK.

TESTING YOUR WOOD

When the stove is thoroughly warmed, place one piece of split

wood (about five inches in diameter) parallel to the door on the

bed of red embers.

Keep the air control full open and close the door. If ignition of

the piece is accomplished within 90 seconds from the time it

was placed in the stove, your wood is correctly dried. If ignition

takes longer, your wood is damp.

If your wood hisses and water or vapor escapes at the ends of

the piece, your wood is soaked or freshly cut (green). Do not

use this wood in your stove. Large amounts of creosote could

be deposited in your chimney, creating potential conditions for

a chimney fire.

This appliance is designed to burn

WOOD FUEL ONLY!

Hardwood, 17” to 19”, should be split and air dried (seasoned)

for 6 months to obtain maximum burning efficiency. Wood

should be stored in a dry, well ventilated area.

Burning fuels other than intended, chemicals, or waste in this

appliance could result in damages to the heater or result in

bodily injury. It will also void any warranty on the appliance.

OPTIMAL FUEL CONSUMPTION

This appliance is designed to get the most efficient transfer of

heat energy from the wood fuel and radiate it into your living

environment. The fire box introduces combustion air through

three sources; (1) Immediately beneath the door opening be

-

low the window is a Lower Primary Air Orifice (LPAO), (2) The

door air inlet control brings air into the firebox and controls the

rate of burn (and the amount of heat the appliance radiates),

(3) The secondary air tubes at the top of the firebox are de

-

signed to ignite the combustion gases (smoke) given off by

the burning wood and increases the efficiency of the appliance

and reduces chimney emissions.

Smoke given off by burning fuel consists of very small organic

liquid droplets. If these droplets condense, they form a sticky

tar-like substance called creosote. When operated properly,

this appliance is designed to burn these droplets. Burning

these droplets releases heat that would otherwise be lost up

the chimney as smoke. Following the instructions below will

help you operate your appliance properly to maximize the ap-

pliance’s performance. Actual performance is dependent on

chimney height, weather, log size, wood species, and moisture

content. Some experimentation will initially be required to find

that spot where your appliance performs best. The following

will give you a starting point to find your optimum settings.

When first loading fuel, set the door air inlet control at the wide

open position for at least 15–20 minutes. When the appliance

is working properly, you should be able to observe second-

ary combustion flames above the fuel pieces in front of the

secondary air tubes at the top of the firebox. These second

-

ary flames should continue to burn after the primary air inlet

Summary of Contents for Country Hearth 2200IE

Page 17: ...17 NOTES...