11

OPERATING INSTRUCTIONS

CAUTION:

DO NOT OVERFIRE APPLIANCE. YOU ARE

OVERFIRING IF ANY PART OF THE APPLIANCE

GLOWS RED. CLOSE THE DOOR AND SHUT

DAMPER IMMEDIATELY TO REDUCE THE AIR

SUPPLY AND SLOW DOWN THE FIRE.

is reset from wide open to the desired operating setting. If the

flames do not continue to burn, open the air control to re-es

-

tablish the secondary flames then slowly reset the air control

to the desired setting. Initially it may take several attempts to

figure your appliance out. But once you find the efficient oper

-

ating spot and the correct mix of procedures to get there, only

minor adjustments will be necessary.

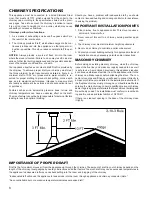

The best indicator of a properly operating appliance is to look

for smoke coming out of the chimney. You may see steam

emissions that will quickly dissipate. Smoke will thin but contin

-

ue to drift without totally disappearing. If you do detect smoke

emissions, open the air control a little bit, let the appliance ad-

just for 10–15 minutes and re-check your chimney. Remember

– visible smoke represents lost heat.

TAMPER WARNING

This wood heater has a manufacturer-set minimum low burn

rate that must not be altered. It is against federal regulations

to alter this setting or otherwise operate this wood heater in a

manner inconsistent with operating instructions in this manual.

EFFICIENCY

Efficiencies can be based on either the lower heating value

(LHV) or the higher heating value (HHV) of the fuel. The lower

heating value is when water leaves the combustion process as

a vapor, in the case of woodstoves the moisture in the wood

being burned leaves the stove as a vapor. The higher heat-

ing value is when water leaves the combustion process com-

pletely condensed. In the case of woodstoves this would as-

sume the exhaust gases are room temperature when leaving

the system, and therefore calculations using this heating value

consider the heat going up the chimney as lost energy. There-

fore, efficiency calculated using the lower heating value of

wood will be higher than efficiency calculated using the higher

heating value. In the United States all woodstove efficiencies

should be calculated using the higher heating value.

The best way to achieve optimum efficiencies is to learn the

burn characteristic of you appliance and burn well-seasoned

wood. Higher burn rates are not always the best heating burn

rates; after a good fire is established a lower burn rate may be

a better option for efficient heating. A lower burn rate slows the

flow of usable heat out of the home through the chimney, and

it also consumes less wood.

NOTICE - INITIAL BURNS TO CURE PAINT

BECAUSE OF THE HIGH OPERATING TEM-

PERATURES, THIS APPLIANCE IS COATED

WITH A SPECIAL HIGH TEMP PAINT WHICH

REQUIRES A SERIES OF LOW TO MEDIUM

BURNS TO FULLY CURE FOR DURABILITY

AND A LIFETIME OF SERVICE.

Proper curing of the high-temp paint requires a series of three

initial burns. The appliance should be allowed to cool off be-

tween each burn. The first two burns should be small fires and

low temperatures (250 degrees F) for a duration of 20 minutes

each. The third fire should be at a temperature of approxi

-

mately 500 F for 20 minutes. Provide adequate cross ventila

-

tion to clear any smoke or odor caused by initial firings.

STARTING A FIRE

DO NOT LEAVE APPLIANCE UNATTENDED WITH DOOR

OPEN! The top down method of fire building is recommended

for this appliance. After making sure that the stove air intake

controls are fully open (completely pull-out towards you),

Place the largest pieces of wood on the bottom, laid in parallel

and close together. Smaller pieces are placed in a second lay-

er, crossways to the first. A third layer of still smaller pieces is

laid crossways to the second, this time with some spaces be-

tween. Then a fourth layer of loose, small kindling and twisted

newspaper sheets tops off the pile. Add large pieces of wood

as the fire progresses being careful not to overload. (Do not

fill firebox beyond firebrick area.) An ideal ember bed of 1 – 2”

should be established to achieve optimum performance. This

unit is designed to function most effectively when air is allowed

to circulate to all areas of the firebox. TIP: If ash or embers

remain in the appliance, make sure to clear them away from

the Lower Primary Air Orifice (LPAO) and rake a slight (1-to-2

inch wide) trough down the center of the embers from front

to back prior to loading the fuel. Once fuel has been loaded,

close the door and leave the air inlet control fully open until fire

is well established (at least 15–20 minutes) being careful not to

over fire (if any of the exterior parts of the appliance or chimney

connections begin to glow you are over firing the appliance).

Re-adjust the door air inlet control to desired burn rate. (If ex-

cessive smoke fills the firebox, open air inlet control slightly

until flames resume and wood is sufficiently ignited.) The basic

rule of thumb is “closed - low,” “half way open - medium” and

“fully open - high.”

VISIBLE SMOKE

The amount of visible smoke being produced can be an ef-

fective method of determining how efficiently the combustion

process is taking place at the given settings. Visible smoke

consist of unburned fuel and moisture leaving your stove.

Learn to adjust the air settings of your specific unit to produce

the smallest amount of visible smoke. Wood that has not been

seasoned properly and has a high wood moisture content will

produce excess visible smoke and burn poorly.

ADDING FUEL

If the embers are not hot and glowing, rake the embers to the

front of the appliance, close the door and adjust the air inlet

control to the wide open position. Let the embers re-heat for

10–15 minutes. When hot and glowing, spread them out and

Summary of Contents for Country Hearth 2200IE

Page 17: ...17 NOTES...