12

place your next fuel load into the appliance (make sure no em-

bers or ashes block the LPAO). Leave the door air inlet control

in the wide open position for 15–20 minutes.

Fuel load size can vary but should be kept 1–2 inches below

the secondary air tubes. Also position the fuel to leave space

so the air from the inlet can work down between the pieces of

fuel. This reduces the time it takes for new fuel to burn properly.

1. When refueling, adjust air inlet control to the fully open

position. When fire brightens, slowly and carefully open

the door. This procedure will prevent gases from igniting

causing smoke and flame spillage.

2.

Add fuel being careful not to overload or overfire the ap

-

pliance.

3.

When adding fuel be careful not to smother the fire. Do

not build fires against glass and make sure the embers do

not obstruct the air inlet. Do not allow logs to roll and strike

the glass.

4. Close the feed door and secure tightly.

5. Adjust the air inlet control as described above.

6. Empty ashes regularly. Do not allow ashes to pile up.

7. Properly dispose of hot ashes.

8.

Do not overfire the appliance (overfiring is when any part

of the appliance’s exterior or chimney connections glow).

OPERATIONAL TIPS

Operational Tips for Good, Efficient, and Clean Combustion

•

Get the appliance hot and establish a good coal bed be-

fore adjusting to a low burn rate (this may take 30 minutes

or more depending on your wood)

•

Use smaller pieces of wood during start-up and a high

burn rate to increase the stove temperature

•

Be considerate of the environment and only burn dry

wood

• Burn small, intense fires instead of large, slow burning

fires when possible

•

Learn your appliance’s operating characteristics to obtain

optimum performance

•

Burning unseasoned wet wood only hurts your stoves ef-

ficiency and leads to accelerated creosote buildup in your

chimney

BLOWER OPERATION

The variable speed blower circulates air warmed by the fire

-

box into the living area to distribute the heat more evenly. The

blower control knob is located on the side of the blower hous-

ing.

Turn the knob clockwise to turn the blower on. The speed is

controlled by turning the knob clockwise for slower speeds and

counter-clockwise for faster speeds. To turn the blower off, turn

the speed control knob fully counter-clockwise. It is recom-

mended to turn the blower off when the unit is not in operation.

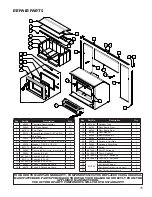

AIR TUBES

The air tubes assembled in this unit are designed to provide an

accurate mix of secondary air to insure the highest efficiency.

Any damage or deterioration of these tubes may reduce the

efficiency of combustion. The air tubes are held in position

by either screws or snap pins. Locate these to either side of

the tube and remove to allow the tube to be removed and re-

placed.

OPERATING INSTRUCTIONS

Summary of Contents for Country Hearth 2200IE

Page 17: ...17 NOTES...