13

CHIMNEY MAINTENANCE

CAUTION:

SLOW BURNING FIRES FOR EXTENDED USE OR

BURNING GREEN WOOD MAY CAUSE EXCESSIVE

CREOSOTE BUILD-UP. IGNITION OF CREOSOTE

OR OVERFIRING COULD CAUSE A CHIMNEY

FIRE. CHIMNEY FIRES BURN EXTREMELY HOT

AND MAY IGNITE SURROUNDING COMBUSTIBLE

MATERIALS. IN CASE OF A CHIMNEY FIRE, CALL

THE FIRE DEPARTMENT IMMEDIATELY!

CREOSOTE -

Formation and Removal

When wood is burned slowly, it produces tar and other

organic vapors which combine with expelled moisture

to form creosote. The creosote vapors condense in the

relatively cool chimney flue of a slow-burning fire and can

accumulate on the flue lining. If ignited, this creates an

extremely hot fire in the chimney which may ignite sur

-

rounding materials resulting in a building fire.

The chimney connector and chimney should be inspected

(at least)

twice a month

during the heating season to

determine if a creosote buildup has occurred. If it has, it

should be removed. Failure to remove creosote may re-

sult in ignition and may cause a house/building fire. Cre

-

osote may be removed using a chimney brush or other

commonly available materials from your local hardware

retailer.

Chimney fires burn very hot. If the unit or chimney con

-

nector should glow red, reduce the fire by closing the inlet

air control and immediately call the fire department.

A fire in the firebox may be smothered by pouring

a large quantity of coarse salt, baking soda, or cool

ashes on top of the fire.

CAUTION:

A CHIMNEY FIRE MAY CAUSE IGNITION OF WALL

STUDS OR RAFTERS WHICH WERE ASSUMED TO

BE A SAFE DISTANCE AWAY FROM THE CHIMNEY.

IF A CHIMNEY FIRE OCCURS, HAVE YOUR CHIMNEY

INSPECTED BY A QUALIFIED EXPERT BEFORE

USING AGAIN.

PREVENTING CREOSOTE BUILD-UP

1. Burn with air control open for several minutes at nu-

merous intervals throughout the day during the heating

season, being careful not to overfire the unit.

2. Burn appliance with air inlet control wide open for

15–20 minutes every time you apply fresh wood. This

allows wood to achieve the charcoal stage faster and

burns wood vapors which might otherwise be depos-

ited within the heating system.

3. BURN ONLY SEASONED WOOD. Avoid burning wet

or green wood. Seasoned wood has been dried for at

least one year.

4. A small hot fire is preferable to a large smoldering one

that can deposit creosote within the heating system.

5. Establish a routine for the handling of fuel, wood

burner and firing technique. Check daily for creosote

buildup until experience shows how often you need to

clean for safe operation. Be aware that the hotter the

fire, the less creosote is deposited, and weekly clean

-

ings may be necessary in mild weather even though

monthly cleanings may be enough in colder months.

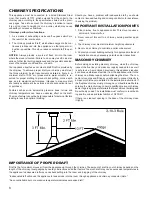

CHIMNEY DRAFT

NOTE: A DRAFT READING OF 0.05[12.45] to

0.06[14.94]

(Water Column[Pascals])

IS REQUIRED

FOR PROPER BURNING OF THIS APPLIANCE.

Draft is a function of the chimney, NOT THE APPLIANCE

— Do not expect the appliance to draw. Smoke spillage

into the house or excess buildup of condensation or creo-

sote in the chimney are warnings that the chimney is NOT

functioning properly. Correct the problem before using

the appliance. Following are some possible causes for

improper draft.

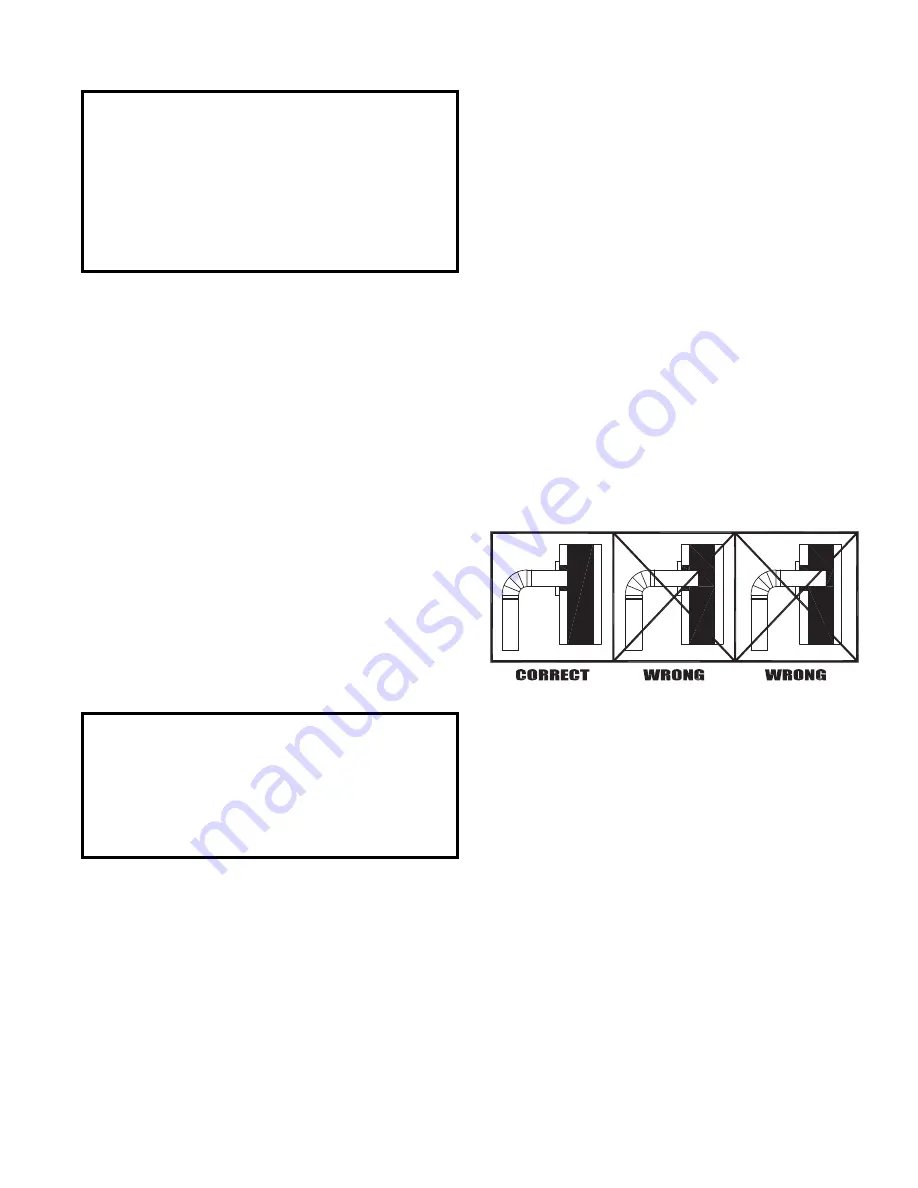

1. The connector pipe may be pushed into the chimney

too far, stopping the draft.

2. If the chimney is operating too cool, water will con-

dense in the chimney and run back into the appliance.

Creosote formation will be rapid and may block the

chimney. Operate the appliance at a fire level high

enough to keep the chimney warm preventing this con-

densation.

3. If the fire burns well but sometimes creates excessive

smoke or burns slowly, it may be caused by the chim-

ney top being lower than another part of the house or

a nearby tree. The wind blowing over a house or tree

falls on top of the chimney like water over a dam, beat-

ing down the smoke. The top of the chimney should

be at least three (3) feet above the roof and be at least

two (2) feet higher than any point of the roof within ten

(10) feet.

Summary of Contents for Country Hearth 2200IE

Page 17: ...17 NOTES...