14

SERVICE HINTS

ASH REMOVAL AND DISPOSAL

Whenever ashes get 3 to 4 inches deep in your firebox or

ash pan, and when the fire has burned down and cooled,

remove excess ashes. Leave an ash bed approximately

1 inch deep on the firebox bottom to help maintain a hot

charcoal bed.

Ashes should be placed in a metal container with a tight-

fitting lid. The closed container of ashes should be placed

on a noncombustible floor or on the ground, away from all

combustible materials, pending final disposal. The ashes

should be retained in the closed container until all cinders

have thoroughly cooled.

SMOKE AND CO MONITORS

Burning wood naturally produces smoke and carbon

monoxide(CO) emissions. CO is a poisonous gas when

exposed to elevated concentrations for extended periods

of time. While the modern combustion systems in heaters

drastically reduce the amount of CO emitted out the

chimney, exposure to the gases in closed or confined

areas can be dangerous. Make sure you stove gaskets

and chimney joints are in good working order and sealing

properly to ensure unintended exposure. It is recommended

that you use both smoke and CO monitors in areas having

the potential to generate CO.

GLASS CARE

The following usage and safety tips should be observed:

1. Inspect the glass regularly for cracks and breaks. If you

detect a crack or break, extinguish the fire immediately

and contact the manufacturer for a replacement.

2. Do not slam the door or otherwise impact the glass.

When closing doors, make sure that logs or other ob-

jects do not protrude to impact the glass.

3. Do not build fires against (or that might fall against) the

glass.

4. Do not clean the glass with materials that may scratch

(or otherwise damage) the glass. Scratches on the

glass can develop into cracks or breaks during opera-

tion.

5. Never attempt to clean the glass while the unit is hot.

If deposits are not very heavy, normal glass cleaners

are adequate using a soft, non-abrasive cleaning pad.

Heavier deposits may be removed with oven cleaners.

6. Never put substances which can ignite explosively in

the unit. Even small explosions in confined areas can

blow out the glass.

Gasket and Glass cleaning products are available at local

retail home centers. Manufacturers of cleaning products

for wood stoves include, A.W. Perkins Co. (www.awper-

kins.com) or Rutland Products (www.rutland.com).

GLASS REPLACEMENT

1. Ensure appliance is not in operation and is thoroughly

cooled.

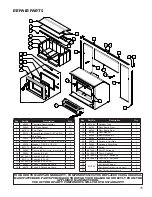

2. Remove screw and glass clip. (See parts list and dia-

gram.)

3. Lift glass out from glass clip.

4. Remove old gasket and clean glass.

5. Replace new gasket starting at the bottom of glass

working along edges, being sure to center gasket chan-

nel on glass.

6. Trim to length and butt ends together.

7. Replace glass into door, being sure not to overtighten

screw and clip.

After extensive use, the gasket material which provides

glass and door seal may lose it’s resiliency and will need to

be replaced. Inspect glass and door gaskets periodically

to ensure proper seal; if gaskets become frayed or worn,

replace immediately.

DOOR GASKET REPLACEMENT

This unit’s door uses a 5/8” diameter rope gasket.

1. Ensure appliance is not in operation and is thoroughly

cooled.

2. Remove old door gasket and clean channel.

3. Using an approved, high temperature gasket cement,

apply a thin coat in bottom of channel.

4. Starting at hinge side of door, work gasket into channel

around door unit, end butt and trim to length.

5. Close door and allow three to four hours for cement to

set before firing appliance.

REMOVING THE INSERT FOR PURPOSE OF INSPECTION.

If for any reason you must remove the insert for inspection

of the appliance or fireplace, follow these rules.

1. Ensure appliance is not in operation and is thoroughly

cooled.

2. Remove the surround by removing the springs retain-

ing it to the appliance.

3. Disconnect the flue gas pipe from the appliance.

4. Slide appliance out to perform inspection.

CAUTION:

REPLACE GLASS ONLY WITH 5mm HIGH

TEMPERATURE CERAMIC GLASS OF THE PROPER

SIZE. DO NOT USE TEMPERED GLASS OR DOUBLE

THICKNESS WINDOW GLASS.

ATTENTION:

THIS WOOD HEATER NEEDS PERIODIC INSPECTION

AND REPAIR FOR PROPER OPERATION. IT IS

AGAINST FEDERAL REGULATIONS TO OPERATE

THIS WOOD HEATER IN A MANNER INCONSISTENT

WITH OPERATING INSTRUCTIONS IN THIS MANUAL.

Summary of Contents for Country Hearth 2200IE

Page 17: ...17 NOTES...