6

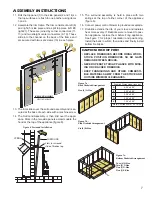

ASSEMBLY INSTRUCTIONS

TOOLS AND MATERIALS REQUIRED FOR INSTALLATION

TOOLS

•

Pencil

• 6 foot Folding Ruler or Measuring Tape

• Tin Snips

• Drill: Hand or Electric

• 1/8” dia. Drill Bit (for sheet metal screws)

• Screwdrivers (Blade and Phillips type)

• 14mm Nut Driver or Ratchet with 14mm Socket

CAUTION: THIS APPLIANCE IS HEAVY. MAKE

SURE THAT YOU HAVE ADEQUATE HELP AND USE

PROPER LIFTING TECHNIQUES WHENEVER MOV-

ING THIS APPLIANCE.

1. Clean the fireplace opening properly disposing of

any ashes in a closed metal container. See Safety

Instructions.

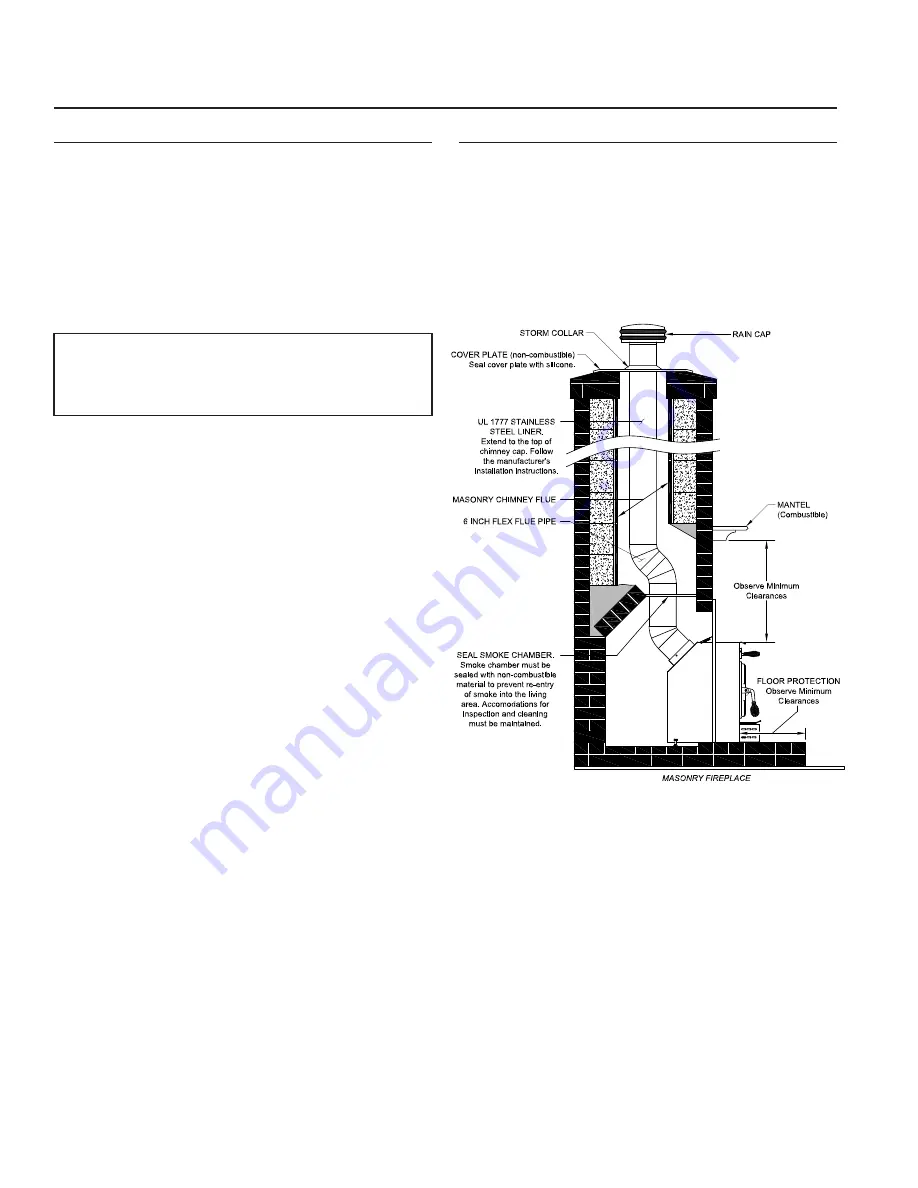

2. Install a 6˝ (152mm) minimum diameter, continuous

stainless steel chimney liner into the existing chim-

ney. The liner must extend to the top of the existing

chimney. Use only listed chimney liners that meet

UL1777 standards. Follow liner manufacturer instal-

lation instructions.

3. Remove or lock the fireplace damper in the open

position. Note: Masonry or damper plate may be re-

moved to accommodate the chimney liner provided

this does not weaken any structural components of

the existing fireplace or chimney nor reduces protec

-

tion of combustible materials required by national

building codes. Consult with your local building or fire

authority before doing this.

4. Uncrate the appliance, remove all packing materials,

and any items stored in the firebox.

5. WARNING: Any fireplace which has had parts re

-

moved or modified to accommodate the installation

of this appliance MUST have a warning plate perma-

nently installed in a visible location stating that the

fireplace is unfit for use with solid fuel. Permanently

attach the warning plate to a visible location in the

fireplace.

6. Position the appliance into the fireplace opening until

the top lip of the air jacket is flush with the fireplace

facing.

8. Level the appliance with the adjusting screws at the

rear of the appliance.

9. Connect the chimney liner to the appliance using a

stainless steel adapter and securing with a minimum

of three (3) sheet metal screws. The liner MUST be

attached with the male (or crimped) end of the adapt-

er inside the flue collar of the appliance to allow con

-

densation and/or creosote to drain back into the fire

-

box.

10. Assemble the Surround. Lay pieces face down on

carpet or other soft surface to protect finish during

assembly. The Surround consists of two side panels,

a top panel, and a decorative trim frame.

MATERIALS

(NOTE: The following items are NOT included with your stove.)

Flooring Protection: as specified herein.

Chimney Liner: Continuous stainless steel chimney liner

(as required)

Stainless Steel Adapter (connects the liner to the flue collar)

1/2” Sheet Metal Screws

Furnace Cement (manufacturer recommends Rutland

Code 78 or equivalent)

Summary of Contents for Country Hearth 2200IE

Page 17: ...17 NOTES...