8

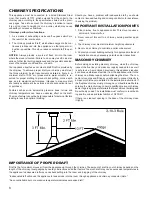

CHIMNEY SPECIFICATIONS

This appliance must be connected to a listed Stainless Steel

Liner, that meets UL1777, which extends from the collar to the

chimney cap according to the specifications listed on the previ

-

ous pages. Take into account the chimney’s location to insure

it is not too close to neighbors or in a valley which may cause

unhealthy or nuisance conditions.

Chimneys perform two functions:

1. As a means of exhausting smoke and flue gases which are

the result of fuel combustion.

2. The chimney provides “draft,” which allows oxygen to be con-

tinuously introduced into the appliance, so that proper com-

bustion is possible. This stove relies on natural draft to oper-

ate.

NOTICE:

Always provide a source of fresh air into the room

where the stove is located. Failure to do so may result in air star-

vation of other fuel burning appliances and the possible develop-

ment of hazardous conditions, fire, or death.

Your appliance itself does not create draft. Draft is provided by

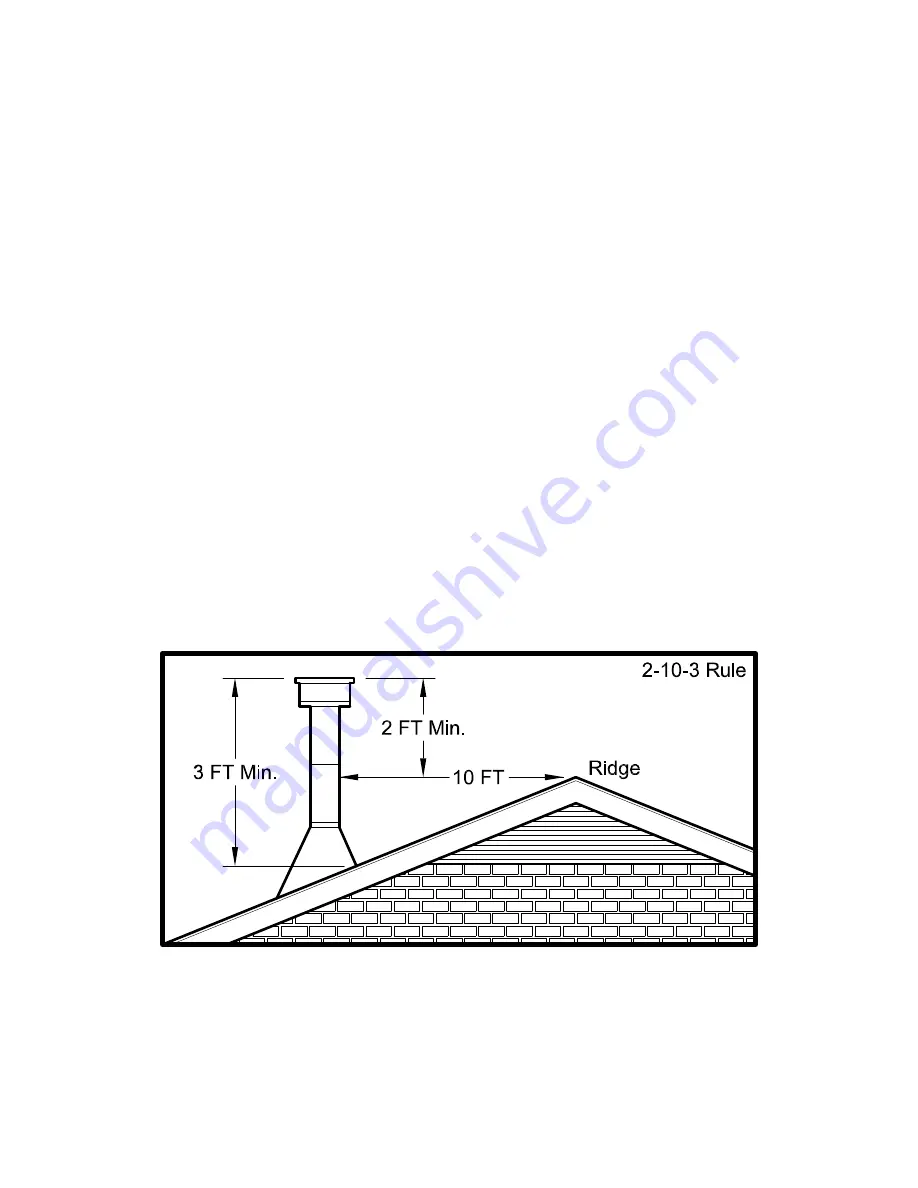

the chimney. To achieve proper draft your chimney must meet

the three minimum height requirements detailed in figure 8. A

minimum draft of 0.05 w.c. (measured in water column) is re-

quired for proper drafting to prevent back puffing, smoke spill

-

age, and to maximize performance. (Gauges to measure draft

are readily available at stove stores and are economical to rent

or purchase.)

Factors such as wind, barometric pressure, trees, terrain and

chimney temperature can have an adverse effect on the draft.

The manufacturer cannot be held responsible for external factors

leading to less than optimal drafting.

Should you have a problem with inadequate draft, you should

contact a licensed heating and cooling contractor for assistance

in solving the problem.

IMPORTANT INSTALLATION POINTS

1. Size chimney flue to appliance collar. This stove requires a

minimum 6” diameter flue.

2. Never connect this unit to a chimney serving another appli-

ance.

3. The chimney must meet all minimum height requirements.

4. Never use a chimney to ventilate a cellar or basement.

5. Contact your local building authority for approved methods of

installation and any necessary permits and/or inspections.

MASONRY CHIMNEY

Before using an existing masonry chimney, clean the chimney,

inspect the flue liner, and make any repairs needed to be sure it

is safe to use. As mentioned previously, this appliance requires

a continuous stainless steel liner from the appliance collar to the

chimney cap. Make repairs before attaching the stove. The con-

nector stove pipe and fittings you will need to connect directly to

a masonry chimney are detailed in the installation instructions. If

the fireplace chimney must go through a combustible wall before

entering the main chimney, consult a qualified mason or chimney

dealer regarding proper materials that meet all local building and

fire authority codes. The installation must conform to local build

-

ing and fire codes and latest edition of NFPA 211.

If there is a cleanout opening in the base of the chimney, close

it tightly.

IMPORTANCE OF PROPER DRAFT

‘Draft is the force which moves air from the appliance up through the chimney. The amount of draft in your chimney depends on the

length of the chimney, local geography, nearby obstructions and other factors. Too much draft may cause excessive temperatures in

the appliance. Inadequate draft may cause backpuffing into the room and ‘plugging’ of the chimney.

“Inadequate draft will cause the appliance to leak smoke into the room through appliance and chimney connector joints.”

“An uncontrollable burn or excessive temperature indicates excessive draft.”

Summary of Contents for Country Hearth 2200IE

Page 17: ...17 NOTES...