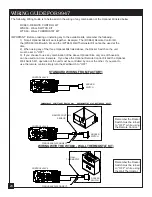

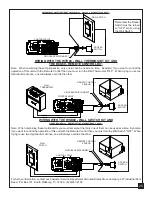

In normal operation at full rate after 15 minutes the following flame appearance should be observed.

FLAMES

The flames behind log #1, and in between log #2, should be yellow with a blue base. (See Below,

Figure 12)

Figure 12. Flames - Natural Gas and LP Gas

Periodic Cleaning

• Do not use cleaning fluid to clean logs or any part of heater.

• Logs - Brush with soft bristle brush or vacuum with brush attachment.

• Vacuum loose particles and dust from the front and rear burner, control, and piezo.

• Inspect burner's and air intake hole. Remove lint or particles with vacuum.

• External case should be dusted and wiped with a wet soapy cloth.

Annual Cleaning/Inspection

• Inspect and clean burner air intake holes.

• Inspect and clean all burner ports.

• Inspect ODS pilot for operation and accumulation of lint at air intake holes.

• Verify flame pattern and log placement for proper operation.

• Verify smooth and responsive ignition of main burner and rear burner.

FLAME APPEARANCE

#1

#2

CLEANING / SERVICING

15

Summary of Contents for Fiero C9947L

Page 16: ...HEATER ASSEMBLY 16 ...

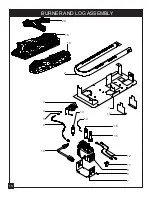

Page 18: ...BURNER AND LOG ASSEMBLY 14 4 2 18 20 19 11 8 9 18 3 5 6 13 16 15 1 12 7 17 10 ...

Page 26: ...NOTES 26 ...

Page 34: ...1 5 HEATER ASSEMBLY REPLACEMENT PARTS 1 2 3 4 5 6 7 8 11 10 9 12 13 ...

Page 36: ...BURNER LOG ASSEMBLY 1 7 5 16 15 6 8 9 2 3 7 4 10 11 17 1 19 18 A B C D 20 13 14 12 ...

Page 41: ...NOTES 2 2 ...