-12-

negative pressure in the house. If such is the case, open a window slightly near the stove and twist together a few

sheets of newspaper into a torch. Light up this paper torch and hold it as close as possible to the mouth of the

pipe inside the combustion chamber to warm up the chimney. Once the updraft movement is initiated, you are

ready to ignite the stove by lighting the paper and kindling wood inside the combustion chamber.

HEATING

Controlled combustion is the most efficient technique for wood heating because it enables you to select the type

of combustion you want for each given situation. The wood will burn slowly if the woodstove air intake control is

adjusted to reduce the oxygen supply in the combustion chamber to a minimum. On the other hand, wood will

burn quickly if the air control is adjusted to admit a larger quantity of oxygen in the combustion chamber. The air

intake control on your stove is very simple. If you pull on it out completely towards you, it is fully open. If you push

on it until it stops the combustion air is reduced to a minimum. Real operating conditions may give very different

results than those obtained during testing according to the species of wood used, its moisture content, the size

and density of the pieces, the length of the chimney, altitude and outside temperature.

EFFICIENCY

Efficiencies can be based on either the lower heating value (LHV) or the higher heating value (HHV) of the fuel.

The lower heating value is when the water leaves the combustion process as a vapor, in the case of woodstoves

the moisture in the wood being burned leaves the stove as a vapor. The higher heating value is when the water

leaves the combustion process completely condensed. In the case of woodstoves, this would assume the

exhaust gases are room temperature when leaving the system, and therefore calculations using this heating

value consider the heat going up the chimney as lost energy. Therefore, efficiency calculated using the lower

heating value of wood will be higher than the efficiency calculated using the higher heating value. In the United

States, all woodstove efficiencies should be calculated using the higher heating value.

The best way to achieve optimum efficiencies is to learn the burning characteristic of this appliance and burn

well-seasoned wood. Higher burn rates are not always the best heating burn rates; after a good fire is established

a lower burn rate may be a better option for efficient heating. A lower burn rate slows the flow of usable heat out

of the home through the chimney, and it also consumes less wood.

VISIBLE SMOKE

The amount of visible smoke being produced can be an effective method of determining how efficiently the

combustion process is taking place in the given settings. Visible smoke consists of unburned fuel and moisture

leaving your stove. Learn to adjust the air settings of your specific unit to produce the smallest amount of visible

smoke. Wood that has not been seasoned properly and has a high wood moisture content will produce excess

visible smoke and burn poorly.

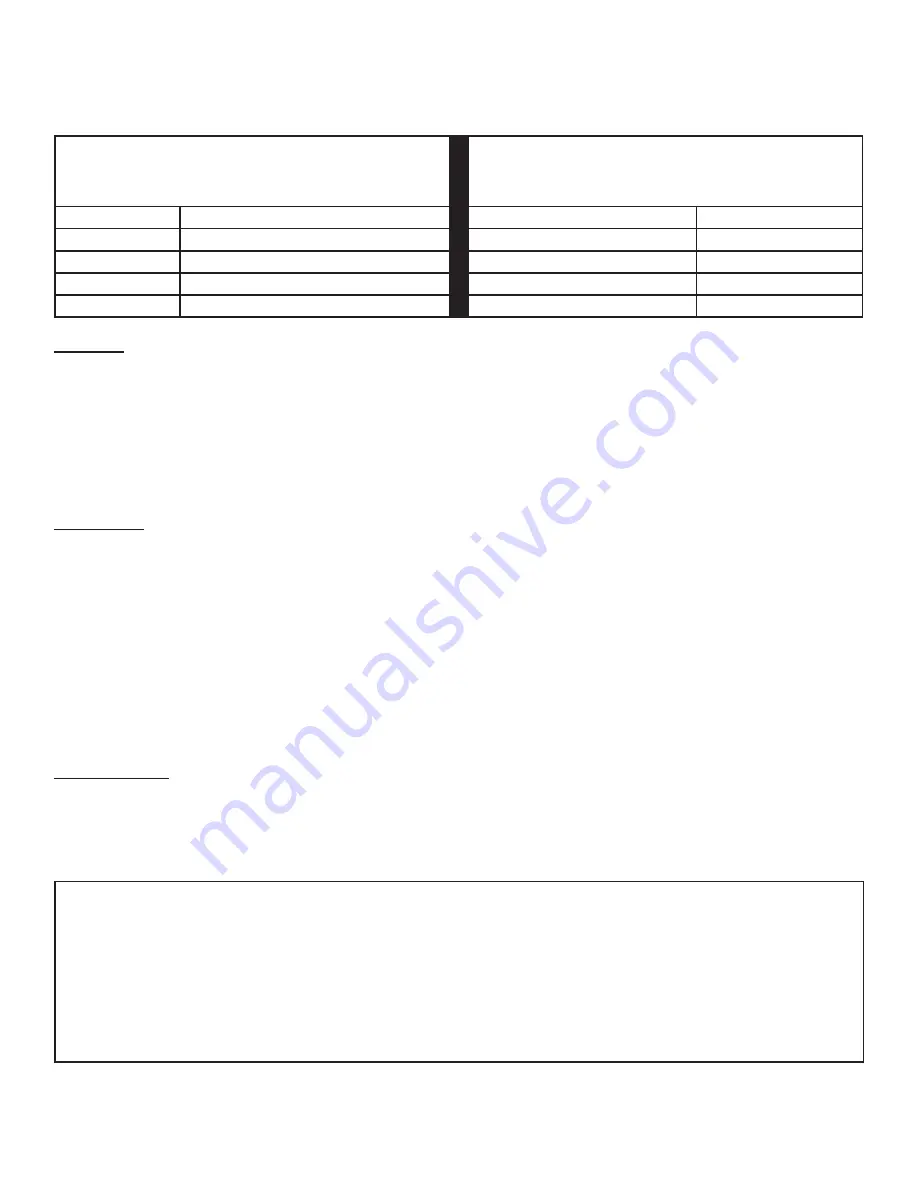

Primary Air Settings

(Slide Damper is located in center of stove under hearth

plate)

(Damper Adjustment: Pulling out on damper increases air)

Electric Blower Speed Setting (Variable)

(Blower is on High when turned “ON”, Rotate clockwise

until stop for “LOW”.)

Burn Rate

Adjust Damper from fully closed

Burn Time

Blower Speed

Low

closed

@ 30 minutes

Low

Medium - Low

approx. 1” (26 mm)

@ 30 minutes

Low

Medium - High

approx. 1.75” (45 mm)

@ 30 minutes

Low

High

approx. 2.3” (59 mm)

Always On

High

WARNINGS:

•

NEVER OVERFIRE YOUR STOVE. IF ANY PART OF THE STOVE STARTS TO GLOW RED, OVER FIRING IS HAPPENING.

READJUST THE AIR INTAKE CONTROL AT A LOWER SETTING.

•

THE INSTALLATION OF A LOG CRADLE OR GRATES IS NOT RECOMMENDED IN YOUR WOOD STOVE. BUILD FIRE

DIRECTLY ON FIREBRICK.

•

NEVER PUT WOOD ABOVE THE FIREBRICK LINING OF THE FIREBOX.

•

ATTEMPTS TO ACHIEVE HEAT OUTPUT RATES THAT EXCEED HEATER DESIGN SPECIFICATIONS CAN RESULT IN

PERMANENT DAMAGE TO THE HEATER.

Summary of Contents for VOGELZANG VG2020

Page 17: ...17 Notes...

Page 18: ...18 Notes...