-4-

Installation

SAFETY NOTICE

•

IF THIS STOVE IS NOT PROPERLY INSTALLED, A HOUSE FIRE MAY RESULT. TO REDUCE THE RISK OF FIRE, FOLLOW

THE INSTALLATION INSTRUCTIONS.

•

CONSULT YOUR MUNICIPAL BUILDING DEPARTMENT OR FIRE OFFICIALS ABOUT PERMITS, RESTRICTIONS AND

INSTALLATIONS REQUIREMENTS IN YOUR AREA.

•

USE SMOKE DETECTORS IN THE ROOM WHERE YOUR STOVE IS INSTALLED.

•

KEEP FURNITURE AND DRAPES WELL AWAY FROM THE STOVE.

•

NEVER USE GASOLINE, GASOLINE-TYPE LANTERN FUEL, KEROSENE, CHARCOAL LIGHTER FLUID, OR SIMILAR

LIQUIDS TO START OR “FRESHEN UP” A FIRE IN THIS HEATER. KEEP ALL SUCH LIQUIDS WELL AWAY FROM THE

HEATER WHILE IT IS IN USE.

•

IN THE EVENT OF A CHIMNEY FIRE, PUSH THE AIR CONTROL FULL CLOSED TO DEPRIVE THE FIRE OF OXYGEN.

CALL THE FIRE DEPARTMENT.

•

DO NOT CONNECT TO ANY AIR DISTRIBUTION DUCT OR SYSTEM.

•

A SOURCE OF FRESH AIR INTO THE ROOM OR SPACE HEATED SHALL BE PROVIDED WHEN REQUIRED.

POSITIONING THE STOVE

It is very important to position the wood stove as close as possible to the chimney, and in an area that will favor

the most efficient heat distribution possible throughout the house. The stove must therefore be installed in the

room where the most time is spent, and in the most spacious room possible. Recall that wood stoves produce

radiating heat, the heat we feel when we are close to a wood stove. A wood stove also functions by convection,

that is through the displacement of hot air accelerated upwards and its replacement with cooler air. If necessary,

the hot air distribution from the stove may be facilitated by the installation of a blower. The wood stove must not

be hooked up to a hot air distribution system since an excessive accumulation of heat may occur. A wood stove

must never be installed in a hallway or near a staircase, since it may block the way in case of fire or fail to respect

required clearances.

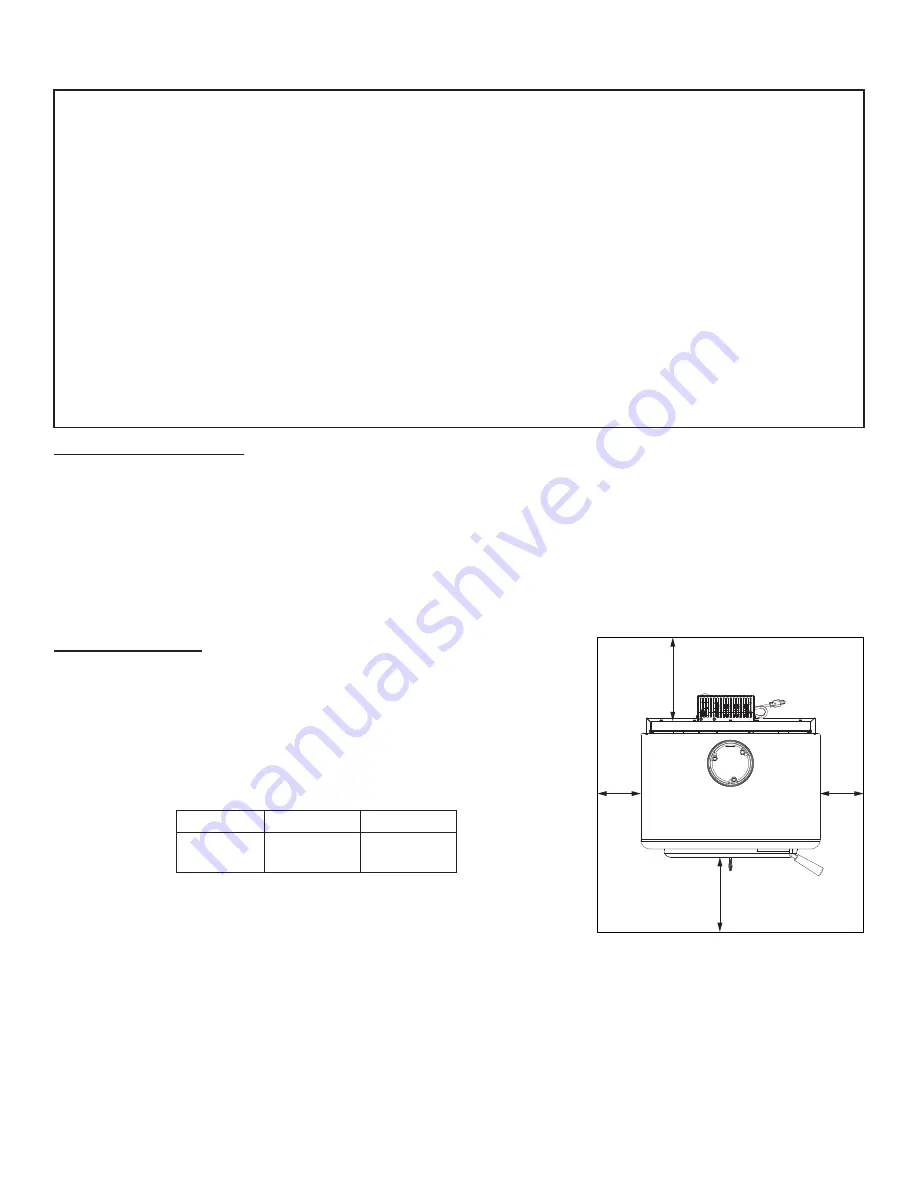

FLOOR PROTECTOR

This heater must have a non-combustible floor protector with an R-Value

of at least 1.4 installed beneath it if the floor is constructed of combustible

material. If a floor pad is used, it should be UL listed or equal. The floor

protector should be large enough to extend under the stove and beyond

each side as indicated. If there is a horizontal run of flue pipe, there needs

to be floor protection under it that extends two inches beyond either side

of the pipe.

The floor protector should exceed the stove as follows:

REAR

FRONT

SIDE

SIDE

Front

Sides

Rear

22”

(559 mm)

8”

(204 mm)

¶

2”

(51 mm)

¶

- Canadian Installations require 8”

(204 mm) to the rear.

Summary of Contents for VOGELZANG VG2020

Page 17: ...17 Notes...

Page 18: ...18 Notes...