10

Install the stovepipe as far as possible

into the thimble, but not past the inside

of the flue lining. There should be a

small air space (approximately 1/2 in.)

between the stovepipe and thimble,

allowing for expansion of the stove-

pipe. Seal this airspace with high-tem-

perature caulking or ceramic wool. Fi-

nally, be sure to wire the damper closed

and apply the same sealant you used at

the stovepipe and thimble junction.

Do not vent up through the fireplace

opening, regardless of whether the fire-

place opening is closed.

MASONRY CHIMNEYS have several

positive attributes: If properly built, they

are quite durable, and most

homeowners consider them more at-

tractive perhaps than a non-enclosed

factory built chimney.

And, if the chimney is located within the

confines of the house (that is, not at-

tached to an exterior wall), its mass

alone will store heat longer and con-

tinue to release the heat long after the

fire has died. Masonry chimneys have

many disadvantages though.

Masonry chimneys constructed on an

exterior wall are exposed to cold out-

door temperatures, promoting greater

heater loss, higher accumulations of

creosote, and reduced draft which leads

to poorer heater or furnace perfor-

mance.

FIREPLACE INSTALLATION

Connection of the stovepipe directly into

the existing masonry chimney over the

fireplace opening is the only approved

method. This installation performs bet-

ter, yielding easy to clean and inspect

for creosote. Before beginning this type

of installation plan carefully; a high de-

gree of skill is required to insure safety.

An entry port for the stovepipe must be

cut through the chimney with minimum

damage to the fire clay liner. Some

involved measurements may be required

to locate the flue liner exactly. Before

cutting, take time to mark the size and

position of the entry port. Position the

entry port so that at least 8 inches of the

flue liner remains below the port.

Keep in mind that wood mantels and

combustible trim around the fireplace

must have adequate clearances from

the heater and stovepipe or must be

protected in an approved manner. Also,

be sure to leave at least 24" clearance

between the top of the stovepipe and

the combustible ceiling or other com-

bustibles. Placing the center of the entry

port 2 feet below the ceiling will insure

proper clearance for 6 inch, 8 inch, and

10 inch stovepipes. Next, install a fire

clay (at least 5/8 in. thick) or metal

thimble, being sure that the thimble is

flush with the inner flue lining. Secure

the thimble in place with refractory mor-

tar. The thimble should be surrounded

on all sides with 8 inches of brickwork

(solid masonry units) or 24 inches of

stone.

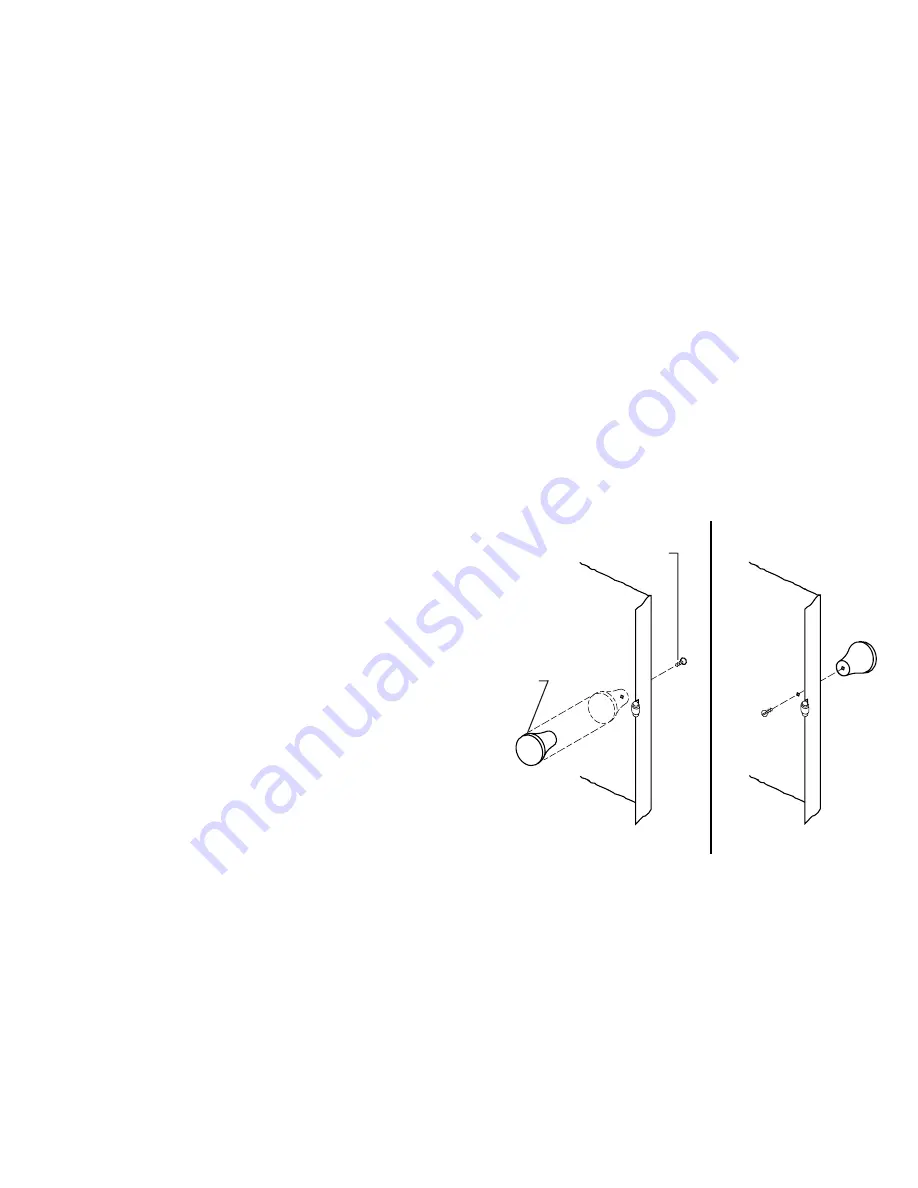

CABINET DOOR KNOB ASSEMBLY

The door knob is mounted inside of the cabinet door to facilitate

shipping and must be reversed for proper usage.

To get cabinet door open, place hand under cabinet frame (right

hand side of cabinet door) and push door out.

INSTALL THE CABINET DOOR KNOB USING THE STEPS

BELOW:

1. Remove the machine screw and door knob (Fig. 9).

2. Place door knob on outside of cabinet door. Then place

machine screw through hole and into door knob and tighten (Fig.

10).

FIG. 9

FIG. 10

CABINET DOOR

KNOB

MACHINE

SCREW

15