RULES FOR CONNECTOR PIPE INSTALLATION

1. The crimped end of the stovepipe fits

inside the heater flue collar. Install ad-

ditional pipe and elbow with the

CRIMPED END TOWARD THE

HEATER. This will allow any

condensation in the flue to run back into

the heater. Smoke will not escape when

installed in this manner.

2. Slope any horizontal pipe upward

toward the chimney at least 1/4 inch for

each foot of horizontal run.

3. You must have at least 18 inches of

clearance between any horizontal pip-

ing and the ceiling.

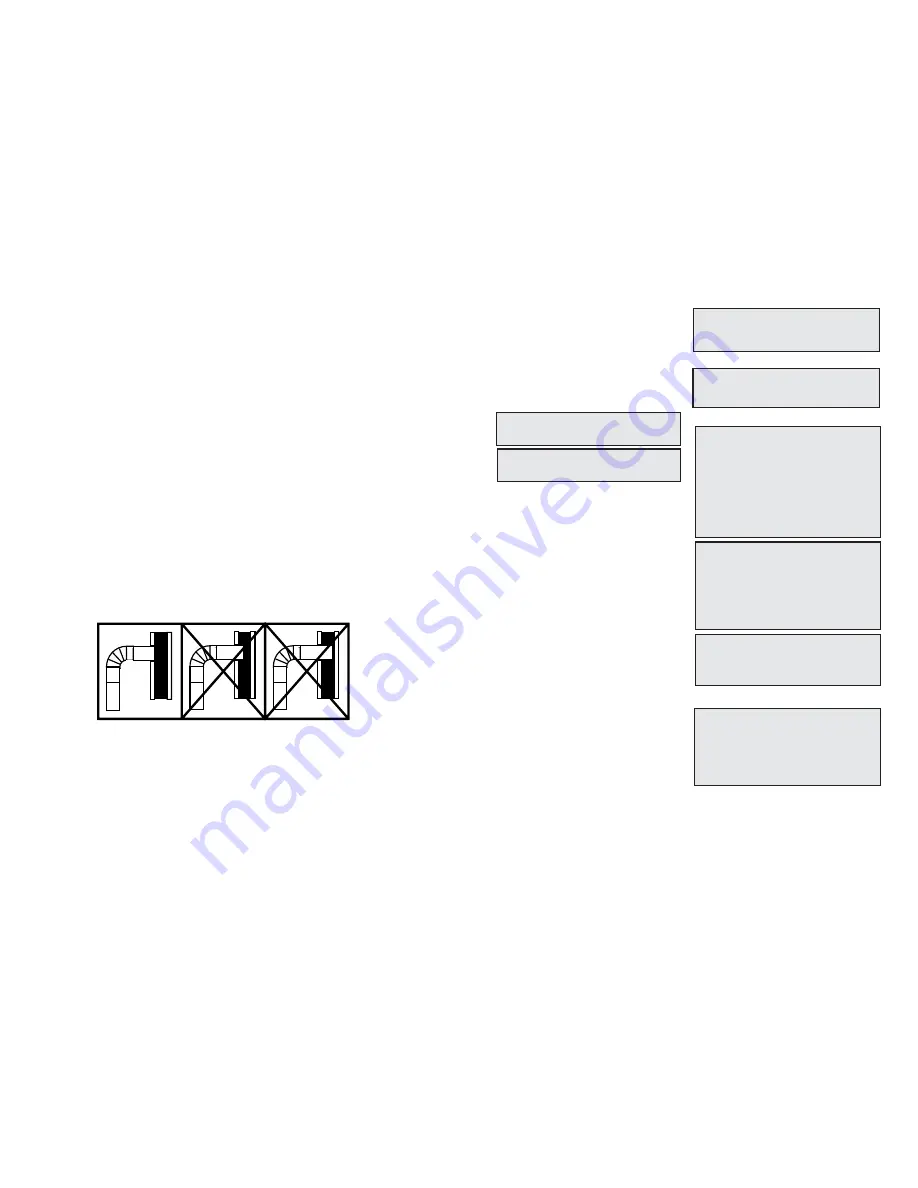

4. The pipe cannot extend into the

chimney flue. (Fig. 8)

5. Seal each connector pipe joint with

furnace cement. Also seal the pipe at

the chimney.

6. Use 3 Sheet Metal screws at each

joint to make the piping rigid.

7. It is recommended that no more than

two 90 degree bends be used in the

stovepipe installation as more than two

may decrease the amount of draw. If

possible, use only corrugated (non-ad-

justable) elbows. They are much more

airtight.

8. The chimney connector must not

pass through an attic or roof space,

closet, or any concealed space, or floor,

ceiling, wall or combustive construction.

OPERATING INSTRUC-

TIONS

FUEL

Hardwood, 18" to 23" should be split

and air dried (seasoned) for 6 months to

obtain maximum burning efficiency.

Wood should be stored in a dry, well

ventilated area. A Wooden box or crate

is ideal for storage.

NOTE: USE SOLID WOOD MATERIAL

ONLY. DO NOT USE COAL.

DO NOT USE MANUFACTURED OR

CHARCOAL LOGS!

LIGHTING

1. Set the thermostat on "High" for

maximum draft.

2. Open the feed door and place paper

and kindling on the grate for starting the

fire.

3. Light fire and close feed door.

4. Add fuel after fire is burning briskly.

Use care not to smother the kindling fire.

5. Set thermostat higher or lower for

desired temperature.

ADDING FUEL

When possible, add small amounts of

fuel each hour or so instead of adding

large quantities of fresh fuel every 4 to

5 hours. This will give more complete

combustion and less build-up of tars or

soot in the chimney.

1. Set Thermostat to HIGH before open-

ing feed door.

2. Empty ash pan regularly. Do not

allow ashes to build up to grate as grate

will warp and burnout will occur, and

you might spill the ashes when remov-

ing the pan. Dispose of hot ashes prop-

erly (see Note 11 on Page 3).

CAUTION: STORING OF WOOD

WITHIN MINIMUM CLEARANCES OF

HEATER MAY CAUSE HOUSE FIRE.

CAUTION: DO NOT OVERFIRE THE

HEATER, AS STATED EARLIER, THIS

CAN PRODUCE A DANGEROUS

CONDITION AND EVEN CAUSE A

HOUSE FIRE. IF ANY PORTION OF

THE HEATER OR ANY CHIMNEY

CONNECTOR GLOWS RED OR DIS-

COLORS, THE HEATER IS BEING

OVERFIRED.

CAUTION: DO NOT OPERATE THIS

HEATER WITH FEED OR ASH DOOR

OPEN. THIS HEATER IS DESIGNED

FOR THERMOSTATIC OPERATION.

OPERATION WITH EITHER DOOR

OPEN WILL OVERHEAT AND DAM-

AGE THE HEATER.

CAUTION:NEVER STORE FLAM-

MABLE LIQUIDS, ESPECIALLY

GASOLINE, IN THE VICINITY OF THE

HEATER.

CAUTION: NEVER USE GASOLINE,

GASOLINE-TYPE LANTERN FUEL,

KEROSENE, CHARCOAL LIGHTER

FLUID, OR SIMILAR LIQUIDS TO

START OR "FRESHEN UP" A FIRE IN

THE HEATER.

CAUTION: BUILD A FIRE ON THE

INTEGRAL GRATE THAT IS PRO-

VIDED WITH THE HEATER.

13

12

RIGHT

WRONG

WRONG

Fig. 8