6

19

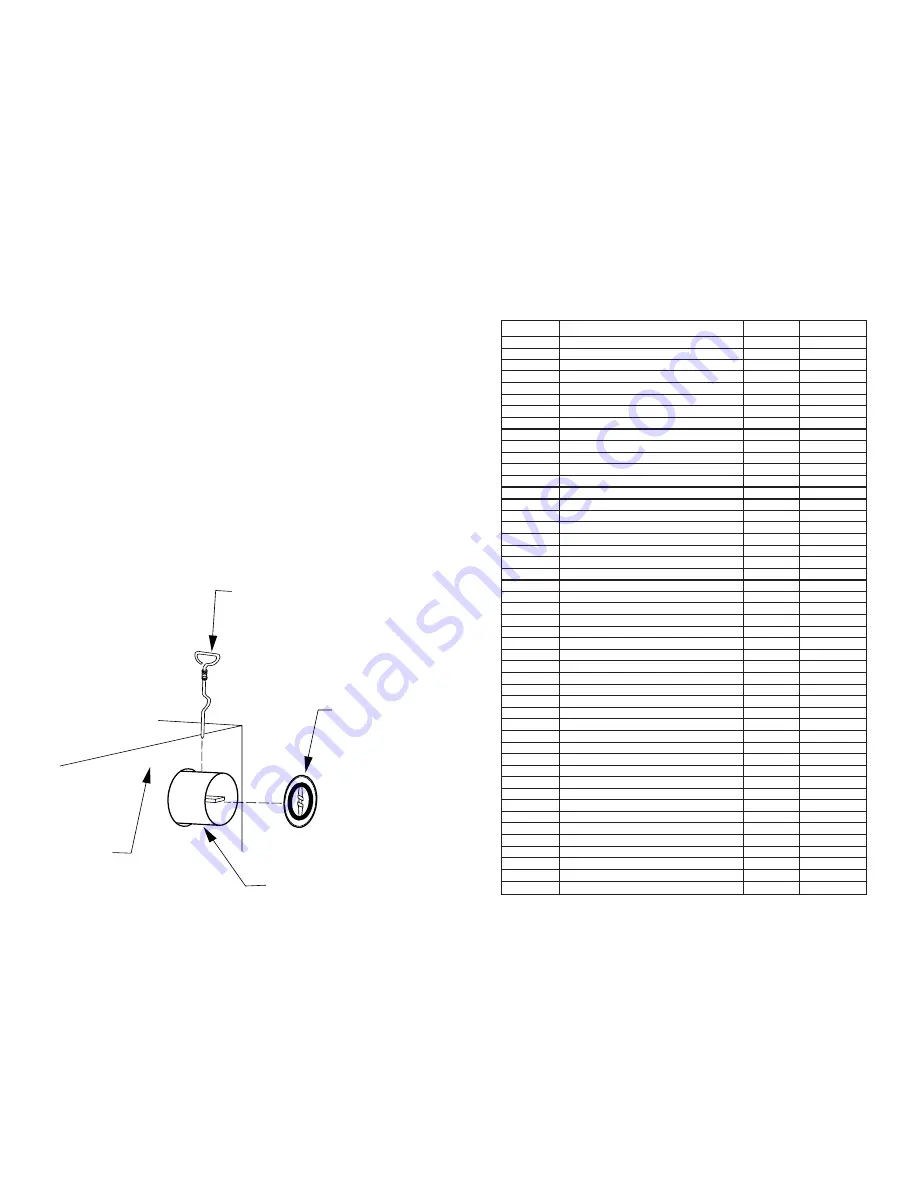

This unit comes equipped with a solid flue damper which is intended to be

installed into the flue collar. The following instructions will help guide you in

installing the solid flue damper.

1.

Before you connect the 6" flue pipe to the flue

collar, place the solid damper inside of the flue

collar on an angle to permit the damper to slide

between to two stops that are welded into the

flue collar.

2.

Place the damper rod into the hole on one side

of the flue collar, aligning it with the flue damper.

Twist the damper rod back and forth as you

slide the damper rod through the flue collar and

solid damper.

3.

Once the damper rod is completely through the

flue collar, lock the damper rod into the solid

damper by pressing in firmly on the damper rod

and twisting. At this point the Damper rod should

be able to open and close the solid damper.

NOTE: This unit has been tested with the cast iron stops in the flue collar to meet

EPA requirements.

SOLID FLUE DAMPER INSTALLATION

REPAIR PARTS LIST - MODEL 2931 (SEE PAGE 18)

AUTOMATIC WOOD BURNING CIRCULATOR

Key No.

Description

Qty.

Part No.

1

Fire Grate

2

40076

2

Ash Pan

1

67444

3

Base

1

67859

4

Draft Damper Hinge Pin

1

17200

5

Draft Damper Frame

1

40075

6

Draft Control Plate

1

23476

7

Clip

2

83818

8

Glass Brass Trim (LH/RH)

2

89382

9

Glass Brass Trim (TOP/BOTTOM)

2

89381

10

Glass Frame

1

68452

11

Glass Gasket

66"

88047

12

Glass (20 1/2"x12 1/2")

1

89409

13

Left Half Brick

1

23782

14

Front Coal Grate

1

40283

15

Flue Collar

1

40343

16

Fire Box Weldment

1

68693

17

Firebrick Retainer

1

40132

18

Firebrick

7

89066

19

Door Hinge Pin

1

83114

20

Feed Door Assembly

1

67775

21

Feed Door Rope Gasket

44"

88033

22

Thermostat

1

67743

23

Thermostat linkage adjustment

1

86191

24

Door Handle

2

40091

25

Flat Washer

1

83045

26

Hex Nut (1/4-20)

2

83250

27

Latch

1

22108

28

Ash Door Rope Gasket

29"

88033

29

Ash Door

1

67781

30

Thermostat Knob

1

89687

31

Front Liner

1

40100

32

Heat Shield

1

23703

33

Draft Damper

1

40282

34

Rear Half Brick

1

23785

35

Left Top Brick Retainer

1

23145

36

Second Heat Shield

1

22030

37

Flue Collar Gasket

1

88032

38

Air Wash Deflector

1

23547

*

Grate Support

2

22536

*

Corner Key (Brass Trim)

10

89419

*

Blank Key (Brass Trim)

10

89420

39

Wood Handle

1

89523

40

Door Hinge Pin

1

23441

41

Door Latch

1

21047

42

Latch Spacer

1

21467

43

Smoke Curtain

1

22090

44

Heat Shield

1

23474

*

Smoke Curtain Bracket

2

22171

*

NOT SHOWN

C

A

S

T

IR

O

N

DAMPE

R

C

A

S

T

IO

R

N

DA

MP

E

R

6

I N CH

SOLID DAMPER

FLUE COLLAR

DAMPER ROD

CABINET BACK