30

BAMOBIL D3.2

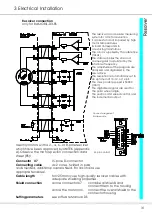

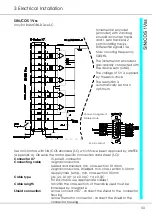

CAN-BUS

The CAN-BUS is a digital connection to the CNC control.

Optimum conditions are achieved with CNC controls and CAN components of

LABOD electronic or CAN Open.

Programming and operation by means of the control panel via the CAN-BUS.

Interface complies with the standard ISO 11898.

Adjustment and programming see Manual DS-CAN.

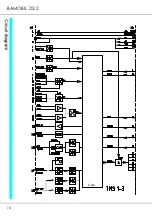

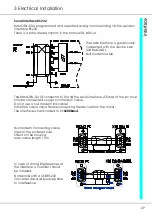

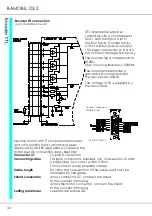

CAN-BUS connection with several BAMOBIL-D3

Master

Address xx

Address xx

Address xx

Terminating resistor at the end of the bus line > 120Ohm between the CAN-H and

CAN-L

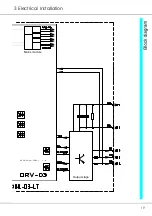

The BUS interface is galvanically

isolated from the internal device

voltage.

.

The voltage is supplied via an

internal, isolated DC-DC

converter or via the BUS cable.

CAN-V+ 9 to 15V=

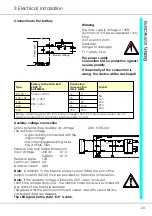

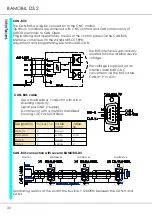

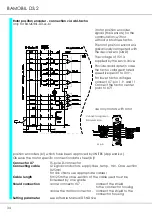

Designation

Connect. no

cable

color

cable

no.

CAN-V+

9

brown

1

CAN-GND

3

white

4

(PE)

CAN-H

7

green

3

CAN-L

2

yellow

2

CAN-BUS cable

Use a shielded bus conductor with a low

shielding capacity.

Signal plus GND (+supply).

D-connector with a metal or metallized

housing. LiYCY 4x0.25+shield.