19 01/2018 - V1

Classic

P3 60-150 A

Commissioning

Co

m

m

iss

io

ni

ng

6

Commissioning

6.1

Commissioning

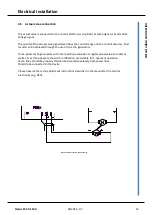

Connect the drive in accordance with the P3 manual and the control electronics manual

(e.g. REG).

Please observe in particular:

Check the power supply voltage with that specified on the type plate

Insert the correct fuses according to the technical data (see contents).

Check the field voltage connection and the motor and tacho connections!!!

For 60Hz applications adjust the switch S2, contact 1 to position 'ON'.

Commissioning

Basic connections:

Mains supply, field, tacho, or armature feedback, drive

enable,

command value

.

For armature voltage control the tacho watchdog must be switched off.

Drive enable switch

open or drive enable voltage 0V/command value voltage 0V

Adjust switch S9 to tacho voltage, adjust to 0 for armature voltage control.

Adjust switch S4 to position 2, switch S5 to position 6.

Adjust the potentiometer

I

max1 to left full scale

Adjust the potentiometer

I

max2 to approx. 10%.

Potentiometer

Xp

to 50%

Potentiometer

I

D

= 100 %

Potentiometer

IxR

= left full scale

Potentiometer

n

max

= left full scale

Potentiometer

INT

= left full scale

DS1:K1, DS2:K4

ON

Bridges R13 and R14 soldered-in (only tacho)

Apply the voltage

The LED L3 (BTB) and the LED L7 (standstill) must light. All other LEDs are off.

Close the switch 'drive enable' or apply a drive enable voltage of >10V

The LEDs L1 and L2 must also light. The drive must be at a standstill or turn slowly (offset

If the drive accelerates in the correct direction, the polarity of the tacho voltage and the armature

voltage feedback must be changed.

If the drive accelerates in the wrong direction, the polarity of the armature or the field must be

changed.

Command value voltage

Increase the command value voltage to 10 %. The drive must accelerate to approx. 10% of the

speed. If the rotation direction is wrong, change the polarity of the tacho and the field

or

the

polarity of the tacho and the armature.