Vision™ OPLC™

Unitronics

7

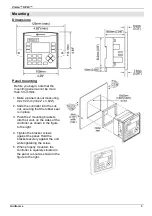

Relay Outputs

Increasing Contact Life Span

To increase the life span of the

relay output contacts and protect

the device from potential damage

by reverse EMF, connect:

A clamping diode in parallel with each

inductive DC load

An RC snubber circuit in parallel with each

inductive AC load

Power Supply

The controller requires an external 24VDC power supply.

A non-isolated power supply can be used if a 0V signal is connected to the chassis.

You must use an external circuit protection device.

Install an external circuit breaker. Guard against short-

circuiting in external wiring.

Double-check all wiring before turning on the power

supply.

Do not connect either the ‘Neutral or ‘Line’ signal of the

110/220VAC to device’s 0V pin.

In the event of voltage fluctuations or non-conformity to

voltage power supply specifications, connect the device

to a regulated power supply.

Earthing the Power Supply

To maximize system performance, avoid electromagnetic interference by:

Mounting the controller on a metal panel.

Earthing the controller’s power supply: connect one end of a 14 AWG wire to the chassis

signal; connect the other end to the panel.

Note: If possible, the wire used to earth the power supply should not exceed 10 cm in

length. However, it is recommended to earth the controller in all cases.