Page 10 of 44

Page 11 of 44

MAN.500.REVD.06302015

DESCRIPTION

A gas sample pump may be provided as part of the sampling system. If the pump is placed ahead of the sample cooler, it

should be provided with a heated head to avoid the condensation of water vapor. If the sample pump is placed after the

sample cooler, drawing the sample through the cooler, the sample has been dried, and a standard, non-heated pump may

be used.

A means to control the flow of the sample through the system should be available and visible to the operator. This may be

accomplished through the use of pressure regulators with gauges, flowmeters, and/or flow control needle valves.

Condensate removal from the heat exchanger(s) within the Sample Cooler can be accomplished through one of the

following methods:

1.

A continuously running peristaltic tubing pump.

2.

Installing the heat exchanger as a bypass condenser, pulling excess sample through with an eductor.

3.

Using float drain traps similar to a steam trap. This requires the sample within the cooler to be at a positive pressure.

4. Use of drain pots on level control with a removal pump.

Description and Principle of Operation

Summary of Contents for 500 series

Page 12: ...Page 12 of 44 MAN 500 REVD 06302015 Electrical Connections Model 520 ...

Page 13: ...Page 13 of 44 MAN 500 REVD 06302015 Electrical Connections Model 530 ...

Page 14: ...Page 14 of 44 MAN 500 REVD 06302015 Electrical Connections Model 540 ...

Page 15: ...Page 15 of 44 MAN 500 REVD 06302015 Electrical Connections Model 560 ...

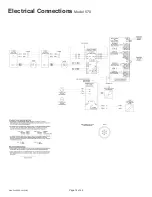

Page 16: ...Page 16 of 44 MAN 500 REVD 06302015 Electrical Connections Model 570 ...

Page 17: ...Page 17 of 44 MAN 500 REVD 06302015 Electrical Connections Model 574 ...

Page 23: ...Page 23 of 44 MAN 500 REVD 06302015 Drawings Model 520 ...

Page 24: ...Page 24 of 44 MAN 500 REVD 06302015 Drawings Model 530 ...

Page 25: ...Page 25 of 44 MAN 500 REVD 06302015 Drawings Model 540 ...

Page 26: ...Page 26 of 44 MAN 500 REVD 06302015 Drawings Model 560 ...

Page 28: ...Page 28 of 44 MAN 500 REVD 06302015 Drawings Model 570 ...