Page 10 of 44

Page 11 of 44

MAN.500.REVD.06302015

Installation

The 500 Series Thermoelectric Gas Coolers are best suited for air conditioned environments. Each unit dissipates

heat, and the surrounding area must be well ventilated to provide adequate cooling. The cooler should be located away

from other heat sources. If located inside an enclosure, outside air should be ducted directly onto the heat sink, and

thermostatically controlled fans and vents should be utilized. The interior of the enclosure should be insulated, and never

mount the unit in direct sunlight to avoid solar heat loading.

Route all sample gas lines directly to the 3/8” inlet tubing fittings located on the top of the cooler heat exchangers. When

two gas streams are being cooled, the left side of the unit is considered to be channel 1, and the right side of the unit is

channel 2. Sample outlet tubing fittings are reduced to 1/4".

At the bottom of each heat exchanger, a 3/8” tubing fitting is provided for the condensate drain. The condensate fitting

may be removed to expose a female 3/8” NPT connection. Equipment must be installed to remove the condensate such

as a peristaltic pump, liquid drainer, or aspirated drainer. A single head peristaltic pump is recommended. If an aspirator

drain is utilized, the outlet tubing should have a small bore and be no longer than two feet to minimize back pressure. The

drain must be run to an appropriate condensate disposal location.

A sample pump is normally required to pull the gas sample through the cooler. A Water Carry-Over Filter (WCOF) sensor

is recommended for each sample path. The pump should be located between the cooler and the filter. A clear glass bowl

should be installed around the filter to allow checking of the condition of the filter while online.

Each cooler consumes about 2 amps (at 115VAC) per every active heat exchanger. Use minimum wire size of 18 AWG,

stranded, tinned copper with a minimum rating of 300 Volts. Dual relays are provided for both the WET/ DRY and HOT/

COLD conditions. One set of relays are MOV protected and designed to interrupt power to the sample pump upon alarm.

The temperature of the heat exchangers may be viewed on the display on the front of the unit. If a multiple channel unit

has been provided, a selector switch on the right side of the display lets the user toggle the display from one block to the

other. For these same cooler models, a second toggle switch on the left side of the display allows the user to view the

settings for the relay and cooler temperatures. Jumpers inside the unit on the control panel allow setting the display for

degrees Celsius or degrees Fahrenheit.

Sample pumps, WCOF sensors, drains, flow meters, regulators, and other optional equipment are available from

Universal Analyzers. These may be purchased separately or installed on a complete 500 Series Sample

Conditioning System.

All installations shall be in accord with the manufacturer’s instructions and the National Electric Code (ANSI/NFPA 70).

Summary of Contents for 500 series

Page 12: ...Page 12 of 44 MAN 500 REVD 06302015 Electrical Connections Model 520 ...

Page 13: ...Page 13 of 44 MAN 500 REVD 06302015 Electrical Connections Model 530 ...

Page 14: ...Page 14 of 44 MAN 500 REVD 06302015 Electrical Connections Model 540 ...

Page 15: ...Page 15 of 44 MAN 500 REVD 06302015 Electrical Connections Model 560 ...

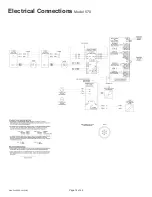

Page 16: ...Page 16 of 44 MAN 500 REVD 06302015 Electrical Connections Model 570 ...

Page 17: ...Page 17 of 44 MAN 500 REVD 06302015 Electrical Connections Model 574 ...

Page 23: ...Page 23 of 44 MAN 500 REVD 06302015 Drawings Model 520 ...

Page 24: ...Page 24 of 44 MAN 500 REVD 06302015 Drawings Model 530 ...

Page 25: ...Page 25 of 44 MAN 500 REVD 06302015 Drawings Model 540 ...

Page 26: ...Page 26 of 44 MAN 500 REVD 06302015 Drawings Model 560 ...

Page 28: ...Page 28 of 44 MAN 500 REVD 06302015 Drawings Model 570 ...