Page 12 of 25

Page 13 of 25

MAN.600.REVF.07012015

Troubleshooting

The following table should give an overview of possible errors and an instruction to check and to repair them (is not valid

for the starting-up period of cooler).

Error

Possible reason

Check/Repair

The presence of water

Overloading of the refrigeration

capacity of the cooler due to too

much water vapor or too great a

sample flow rate.

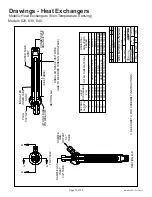

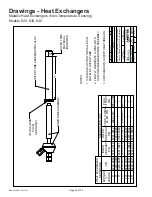

A fault in the condensate removal

equipment. The heat exchanger has

become full of condensate.

An air leak in the condensate

removal tubing.

The temperature of the air passing

through the heat sink is too high due

to the cooler being in an enclosed

box.

Failure of the sample cooler.

No sample gas flow

Heat exchanger plugged

Alarm shutoff

No power on cooler

Check for an obstruction

Remove heat exchanger from unit and

disassemble

Verify cool & dry indicators are Illuminated

Ensure cooler has power supplied

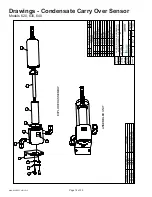

Condensate carry-over sensor

alarm/dry light not illuminated

Inadequate drain apparatus

Excessive flow rate

High ambient temperature

Defective cooler

Verify drain tubing is unobstructed and

equipment is functioning satisfactory

Reduce the flow rate

Reduce the ambient temperature (Increase

ventilation or relocate cooler)

Verify air flow across the heat sink

Hold hand in front of heat sink fins and

ensure air movement.