Page 12 of 43

Page 13 of 43

MAN.SCPSCU.REVD.03022015

Start-Up

NOTE: IT IS IMPORTANT THAT THE HEATED PROBE AND HEATED SAMPLE LINE SHOULD BE AT

OPERATING TEMPERATURE BEFORE STARTING THE CHILLER AND SAMPLE PUMP.

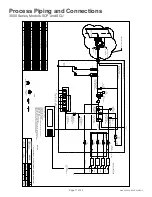

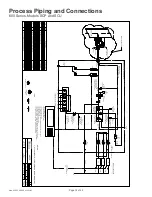

Apply power to the sample conditioning plate or U-bracket. The indicated temperature will start to drop immediately. It

should be below the over-temperature alarm point in approximately four minutes and the “COOL” green LED lamp should

light. When the temperature reaches the control set point, the rate at which the temperature drops will be reduced. The

temperature will stabilize within 1°C of the control set point.

Once the cooler temperature has been reduced to approximately 10°C to 9°C the sample pump will start. Factory

setting of the flow rate is 10 PSIG at mid scale of combined flow meters going to the analyzers. Each flow meter has

an adjustable valve to provide a flow rate as needed for each of the individual sample output. If additional or reduced

pressure is required there is an adjustable pressure regulator located at the pump.

The green “DRY” LED light will be on at start-up. The light will go out and the alarm relay de-energized when the sensor

detects condensate. A test can be performed by putting water on the moisture sensor. The sample pump is powered

through the alarm relay contacts, it will cease running. When the moisture sensor is wiped dry, the sample pump will start.

Turn on the analyzer(s) and initiate the calibration cycle.

Shutdown

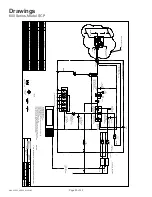

Before removing power from the unit, ensure the system has been purged of any potentially hazardous components.

To purge the system, perform the following:

1. Perform a manual blowback operation.

2. If feasible, provide instrument air to the prove via a cal gas line. If not, disconnect the sample line.

3. Allow the system to run for at least 10 minutes to remove remaining condensate from heat exchangers.

4. Once purging is complete disconnect the sample outlet tube connections and disconnect power from the unit.

Note: If electrical wires are to be disconnected, follow applicable 'Lock Out/Tag Out" requirements.