Page 14 of 43

Page 15 of 43

MAN.SCPSCU.REVD.03022015

Maintenance

MAINTENANCE SCHEDULE

The cooler heat sink is used to dissipate heat away from the heat transfer block/ Peltier elements. Over time in an

industrial environment, dust/ debris can build up between the fins on the back side of the heat sink. This build will reduce

the efficiency of the cooler and can cause premature failure of the Peltier elements.

INSPECT HEAT SINK FINS

Using a flash light (or other light source), shine a light through the heat sink fins. If the fins are unobstructed, you should

be able to see the aluminum blower fins. If the blower is not visible or partial obstruction exists, clean the heat sink fins.

CLEAN HEAT SINK FINS

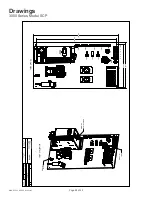

Access to the left side of the cooler is required.

First, remove the side panel from the unit. Remove the screws securing the side panel. Once the panel is loose,

disconnect all electrical connectors from the power supply board.

Looking in from the left side, the blower assembly should be visible at the rear of the enclosure. Immediately in front

of the blower is the inlet side of the heat sink. Using a soft bristled brush, gently remove to debris from the heat sink.

Alternatively, a computer safe aerosol cleaner can be used to remove the debris.

Clean any loose debris from the enclosure and blower motor using a vacuum or compressed air. Replace all

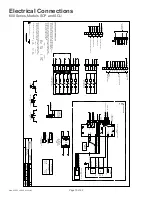

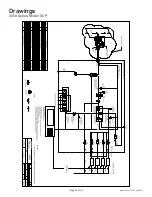

connectors, reference electrical drawings below for details. Reinstall the side pane.

CLEANING INSTRUCTIONS

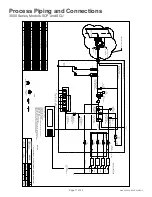

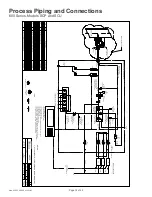

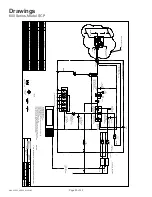

Should the Heat Exchangers require cleaning, disconnect the tubing and remove the Exchangers from the Heat Transfer

Blocks. Wipe off the white heat sink compound with a clean rag. Disassemble the Exchanger. Refer to Drawing Numbers

P0147 through P0149 for an illustration on the assembly of the exchanger. Wipe off all surfaces with a clean rag.

STAINLESS STEEL EXCHANGER (IF REQUIRED)

a) Soak in soap and water solution, or

b) Soak in Solvent such as MEK, Acetone, etc. or

c) Soak in a 10% HNO

3

solution

PV (GLASS & KYNAR) (IF REQUIRED)

a) Soak in Alcohol to remove hydrocarbons

DO NOT USE MEK, ACETONE OR SIMILAR SOLVENTS ON PV EXCHANGERS

Re-assemble Exchangers with new O-Ring(s). Apply an even coat of Heat Sink Paste to the exterior of the exchanger

tube only. Re-install into Heat Transfer Block and reconnect tubing.