Page 6 of 43

Page 7 of 43

MAN.SCPSCU.REVD.03022015

Description and Principle of Operation

APPLICATION

In order to analyze combustion products or incinerator effluents utilizing a direct extractive sampling technique, it is

important to remove the water vapor without removing the water soluble fraction(s) from the gas sample. The heat

exchangers (impingers) used in the Universal Analyzers gas sample coolers are designed to minimize the gas/condensate

area and time of contact to reduce to a minimum, the amount of mass transfer of those water soluble components from

the gas phase into the liquid phase. The result is a dry gas sample which has the same composition on a dry basis before

and after passing through the chiller.

A gas sample is usually taken from a stack with a probe extending into the stack. The heated probe filter is maintained at

a temperature above the dew point of the stack gas, usually 300

°F

to 400

°

F (149°C to 204°C), in order to avoid cementing

the filtered particulates to the filter medium with condensate. A means is usually provided to automatically blow the

particulates trapped by the filter back into the stack on a periodic basis.

The stack gas sample is clean but “wet” after passing through the filter assembly. The moisture in the gas sample comes

from the fuel as a product of combustion, from the humidity in the air which supports the combustion and from the water

content which was trapped in the fuel. This latter source of water in the sample can be from burning moist coal, wet

garbage, or from water injected into the fire box. Water from all of these sources will remove the water soluble gases

from the sample stream if allowed to condense in the sample line prior to the controlled separation within the Universal

Analyzers’ heat exchangers in the sample cooler.

In order to maintain the temperature of the gas sample above the dew point as it is transported to the gas sample cooler,

a heat traced sample line is usually employed. The heat traced sample line can be very short if the gas sample cooler is

located close to the heated stack filter or it could be several hundred feet long if the gas sample cooler is located in the

analyzer shack some distance from the stack.

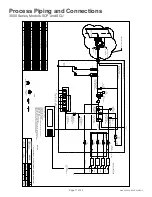

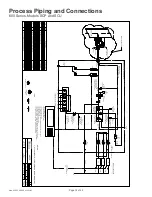

The Universal Analyzers gas sample cooler contains the special impinger type heat exchanger(s). These are mounted

within heat transfer blocks which are cooled by thermoelectric elements utilizing the “Peltier Effect” discovered in

France over half a century ago. Where high water contents are encountered, it is efficient to remove the condensate

in two stages, one at the temperature of the air in the vicinity of the “Precooler” and then by passing the sample into

a heat exchanger cooled by the thermoelectric elements. The precooler can remove water which will condense at the

temperature of the environment. In high water content samples, this could be as much as 80% of the water in the sample.

The thermo-electrically cooled stage is temperature controlled at a factory setting of 4°C (39°F).

The gas sample conditioning system contains additional components to insure that a clean, dry sample is presented to the

analyzer for minimum analyzer maintenance. The water carry over sensor with filter (WCSF) provides the opportunity to

detect if moisture has traveled past the cooler and alarms to indicate a problem with a part of the sample system (possibly,

but not limited to the cooler). The WCSF consists of a coalescing filter (ceramic standard), transparent bowl, and

capacitance sensor. The capacitive sensor allows for detection of any liquid or solid that has passed into the transparent

bowl, including distilled water with no ions present.

DESCRIPTION

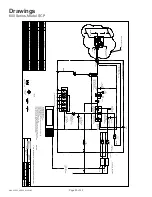

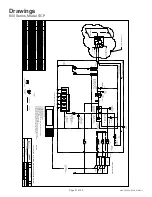

The key to the success of the Universal Analyzers Sample Cooler is being able to condense the water from a wet gas

sample with a minimal loss of the water soluble gas fraction is due to the design of the heat exchanger. Please refer to

Drawings P0147 and P0149. The separation occurs in a classical impinger which has a highly polished cylindrical surface

cooled to the desired dew point temperature. The hot wet sample is brought to the bottom of the cylinder through an

insulated tube and allowed to rise through a narrow annular area at a relatively high Reynolds number to insure the entire

sample is influenced by the cold surface. The condensate falls down the cold polished surface in the form of a sheet

(as opposed to droplets or the bubbling of the gas sample through the condensate) which minimizes the surface area in

contact with the gas sample.